filmov

tv

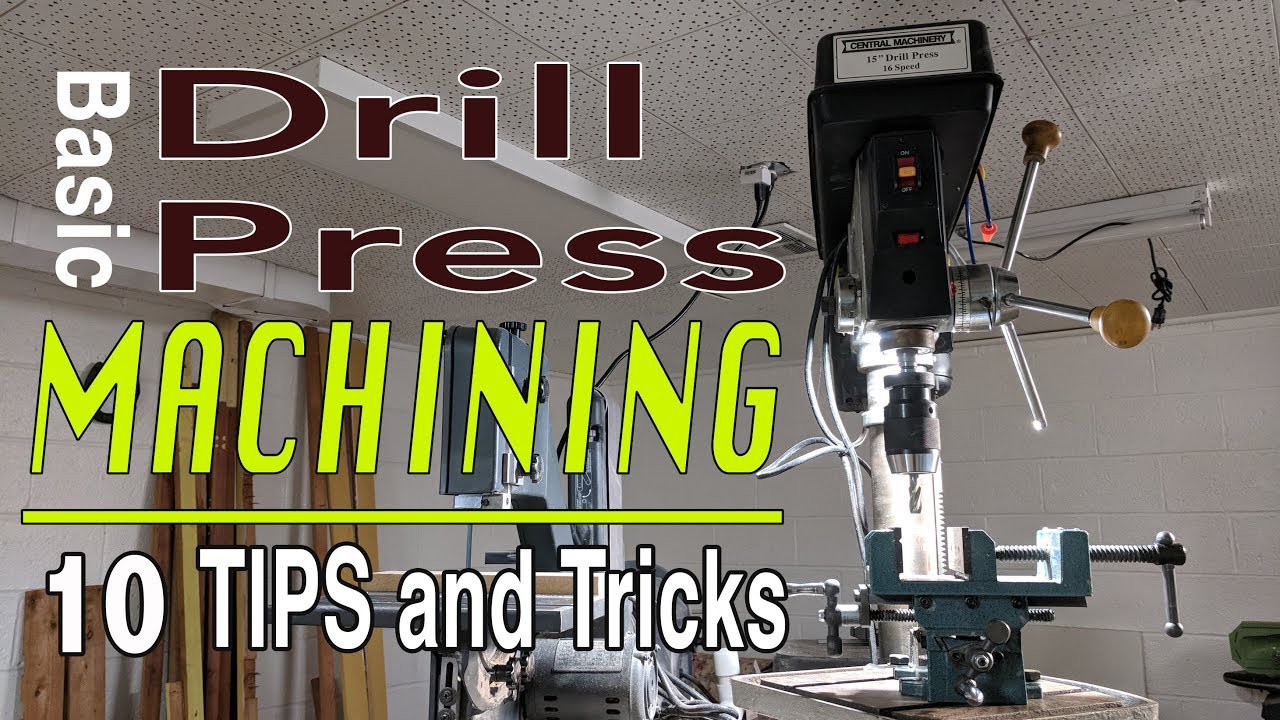

Drill Press Machining Hacking/Tips and Tricks: The Basics

Показать описание

10 Bake-sale Basic Machining hacks/Tips and Tricks for your Drill Press.

I cover some of the basics to use your drill press to do some basic machining.

Never miss a video! Enable '🔔' All Notifications!

1/32-5/8" Keyless chuck is from CME-tools in Michigan

As an Amazon,Bambu,Blick Associate I earn from qualifying purchases.

My Video Gear:

PANASONIC LUMIX G X Vario Power Zoom Lens, 14-42MM Power O.I.S

Samsung 128Gb MicoSD card with adapter

Zhiyun Crane V2 3 Axis Brushless Handheld Gimbal Stabilizer

Pergear Tripod Tabletop Stand for the Zhiyun Handheld Gimbal Stabilizer

My Audio Gear:

My Hardware:

you can follow me on:

Botzen Design Inc.

Industrial Design and Product Visualization

I cover some of the basics to use your drill press to do some basic machining.

Never miss a video! Enable '🔔' All Notifications!

1/32-5/8" Keyless chuck is from CME-tools in Michigan

As an Amazon,Bambu,Blick Associate I earn from qualifying purchases.

My Video Gear:

PANASONIC LUMIX G X Vario Power Zoom Lens, 14-42MM Power O.I.S

Samsung 128Gb MicoSD card with adapter

Zhiyun Crane V2 3 Axis Brushless Handheld Gimbal Stabilizer

Pergear Tripod Tabletop Stand for the Zhiyun Handheld Gimbal Stabilizer

My Audio Gear:

My Hardware:

you can follow me on:

Botzen Design Inc.

Industrial Design and Product Visualization

Drill Press Machining Hacking/Tips and Tricks: The Basics

5 Amazing and Useful Ideas for Drill Press Machine

10 Simple Drill Press Hacks || Woodworking Ideas

EASY Drill Press Mod I Should Have Done Years Ago

Can You Use Router Bits In A Drill Press??? Lets Find Out!

Milling Without A Mill! (On The Drill Press) | Güth Blades

3 drill tips and tricks - life hacks woodworking

OLD MACHINIST TAUGHT ME THIS DRILL PRESS HACK! Works Amazingly well!!

This Cheap Drill Press Hack Will Have You Drilling With Pinpoint Precision! #toolhacks

5 Quick DRILL PRESS Hacks - Woodworking Tips and Tricks

Drill press hack. #drill #hacks #ideas #smart #mechanic #mechanical

12 Ingenious Intelligent Secrets & Tips That Work Extremely Well. Valued woodworking Tricks &...

4 EASY and Useful Ideas for Drill Press

10 clever things to do with a drill press

Drill press hack. No metal lathe? No problem! FarmCraft101

Top 7 Drill Hacks | Drill Powered Tools

9 Best Drill Hacks | DIY Woodworking

Using a Drill Press as Metal Lathe - Simple Life Hack

Shop Tip - Drill Press Vise Quick Release

Essential Skills in Woodworking - Drill Press Tips and Tricks

Drill, Thread, and Chamfer with 1 Tool

Drill Press Mortising made easy

How to Make a Drill Press Into a Milling Machine

5 Quick Drilling Hacks Part 2 - Woodworking Tips and Tricks

Комментарии

0:06:51

0:06:51

0:10:07

0:10:07

0:16:53

0:16:53

0:04:47

0:04:47

0:06:54

0:06:54

0:08:41

0:08:41

0:14:11

0:14:11

0:02:42

0:02:42

0:00:45

0:00:45

0:05:18

0:05:18

0:00:25

0:00:25

0:05:13

0:05:13

0:13:30

0:13:30

0:03:24

0:03:24

0:04:02

0:04:02

0:12:21

0:12:21

0:21:58

0:21:58

0:12:43

0:12:43

0:01:41

0:01:41

0:05:42

0:05:42

0:00:23

0:00:23

0:08:26

0:08:26

0:01:18

0:01:18

0:08:45

0:08:45