filmov

tv

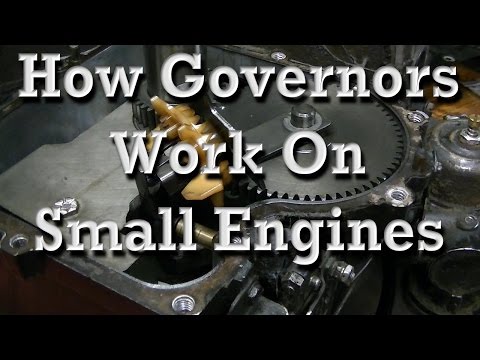

How a Mechanical Governor Works on a 4-Stroke Lawnmower Engine

Показать описание

This How a Mechanical Governor Works on a Small Four Stoke Lawn mower Engine.

This video shows you how the mechanical governor works on a 4 Stroke Lawn mower, but the principles of this can be applied to the workings of an Engine Governor in general.

So, whether you are using a Riding lawn mower, Push mower, Petrol lawnmower or even an electric lawn mower, this principle could possibly be valid. The Robot Lawn mower doesn't escape this principle either!

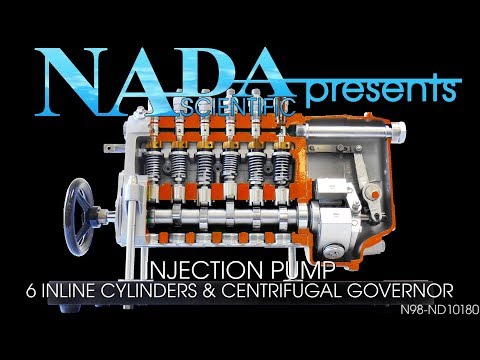

Four-stroke internal combustion engines frequently employ a mechanical governor system to control engine speed and maintain a constant RPM (revolutions per minute) under a variety of load circumstances. To maintain smooth operation and avoid overspeeding or underspeeding, the governor system helps regulate the fuel flow to the engine.

A four-stroke engine's mechanical governor system is described in the following manner:

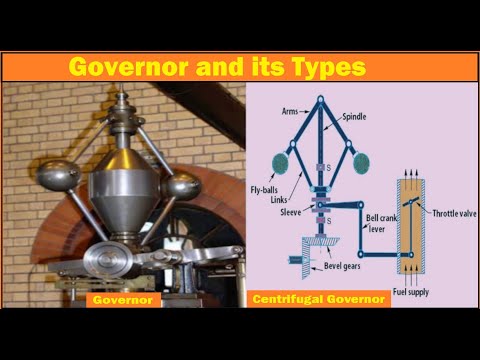

The mechanical governor system consists of the following essential components:

Flyweights, a control lever, and the governor shaft are all part of the governor assembly.

The throttle regulates how much gasoline and air are injected into the engine.

Control Springs: The governor system requires a certain amount of tension from these springs in order to function properly.

The governor assembly is joined to the throttle mechanism by linkages.

Sensing Engine Speed: The governor system keeps track of the engine speed. This is accomplished either by a governor gear installed on the flywheel or by a magnetic pickup that measures the engine's rotational speed. The governor assembly is connected to the governor gear, also known as the magnetic pickup. Two flyweights are a part of the governor assembly and are fastened to the governor shaft. The flyweights are subjected to an increase in centrifugal force as engine speed rises. The governor shaft is rotated by this force, which also causes the flyweights to travel outward.

Control Lever and Linkages: A control lever that is attached to the throttle mechanism is connected to the governor shaft. The control lever is engaged when the flyweights shift outward as a result of increasing engine speed, and it changes the throttle position appropriately. The control lever limits the throttle if the engine speed is too high, decreasing the fuel supply to the engine. The control lever closes the throttle to decrease the fuel flow when the engine speed rises.

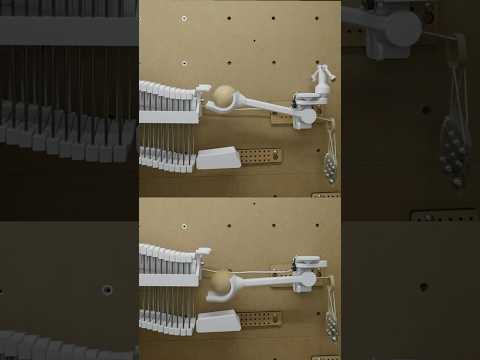

The governor system works on the basis of a feedback mechanism. The engine speed is impacted as the throttle position is changed by the control lever. The governor gear or magnetic pickup detects a change in engine speed, and the flyweights adjust to maintain the correct RPM.

The governor mechanism also makes adjustments for changes in load. The governor system detects the decrease in engine speed when the engine sees an increase in load, such as when more devices are connected or the workload increases. In response, it opens the throttle to give the engine more fuel, making up for the extra load and keeping the appropriate RPM.

Overall, a four-stroke engine's mechanical governor system is crucial for controlling engine speed and guaranteeing reliability. The governor system keeps the RPM steady so that the engine can run smoothly and efficiently under a variety of load conditions by monitoring engine speed, spotting variations, and regulating the throttle position.

I hope you gain something from this.

Many thanks indeed

Craig (Owner and Creator of The Repair Specialist Channel)

#MechanicalGovernor

#EngineSpeedControl

#FourStrokeEngine

#RPMRegulation

#EnginePerformance

#ThrottleControl

#Flyweights

#LoadAdjustment

#ConstantRPM

#GovernorSystem

#EngineGovernor

#EngineSpeedSensor

#FlywheelGovernor

#MechanicalControl

#ThrottlePosition

#LoadVariations

#EngineStability

#GovernorMechanism

#ControlLevers

#SpeedFeedback

This video shows you how the mechanical governor works on a 4 Stroke Lawn mower, but the principles of this can be applied to the workings of an Engine Governor in general.

So, whether you are using a Riding lawn mower, Push mower, Petrol lawnmower or even an electric lawn mower, this principle could possibly be valid. The Robot Lawn mower doesn't escape this principle either!

Four-stroke internal combustion engines frequently employ a mechanical governor system to control engine speed and maintain a constant RPM (revolutions per minute) under a variety of load circumstances. To maintain smooth operation and avoid overspeeding or underspeeding, the governor system helps regulate the fuel flow to the engine.

A four-stroke engine's mechanical governor system is described in the following manner:

The mechanical governor system consists of the following essential components:

Flyweights, a control lever, and the governor shaft are all part of the governor assembly.

The throttle regulates how much gasoline and air are injected into the engine.

Control Springs: The governor system requires a certain amount of tension from these springs in order to function properly.

The governor assembly is joined to the throttle mechanism by linkages.

Sensing Engine Speed: The governor system keeps track of the engine speed. This is accomplished either by a governor gear installed on the flywheel or by a magnetic pickup that measures the engine's rotational speed. The governor assembly is connected to the governor gear, also known as the magnetic pickup. Two flyweights are a part of the governor assembly and are fastened to the governor shaft. The flyweights are subjected to an increase in centrifugal force as engine speed rises. The governor shaft is rotated by this force, which also causes the flyweights to travel outward.

Control Lever and Linkages: A control lever that is attached to the throttle mechanism is connected to the governor shaft. The control lever is engaged when the flyweights shift outward as a result of increasing engine speed, and it changes the throttle position appropriately. The control lever limits the throttle if the engine speed is too high, decreasing the fuel supply to the engine. The control lever closes the throttle to decrease the fuel flow when the engine speed rises.

The governor system works on the basis of a feedback mechanism. The engine speed is impacted as the throttle position is changed by the control lever. The governor gear or magnetic pickup detects a change in engine speed, and the flyweights adjust to maintain the correct RPM.

The governor mechanism also makes adjustments for changes in load. The governor system detects the decrease in engine speed when the engine sees an increase in load, such as when more devices are connected or the workload increases. In response, it opens the throttle to give the engine more fuel, making up for the extra load and keeping the appropriate RPM.

Overall, a four-stroke engine's mechanical governor system is crucial for controlling engine speed and guaranteeing reliability. The governor system keeps the RPM steady so that the engine can run smoothly and efficiently under a variety of load conditions by monitoring engine speed, spotting variations, and regulating the throttle position.

I hope you gain something from this.

Many thanks indeed

Craig (Owner and Creator of The Repair Specialist Channel)

#MechanicalGovernor

#EngineSpeedControl

#FourStrokeEngine

#RPMRegulation

#EnginePerformance

#ThrottleControl

#Flyweights

#LoadAdjustment

#ConstantRPM

#GovernorSystem

#EngineGovernor

#EngineSpeedSensor

#FlywheelGovernor

#MechanicalControl

#ThrottlePosition

#LoadVariations

#EngineStability

#GovernorMechanism

#ControlLevers

#SpeedFeedback

Комментарии

0:04:51

0:04:51

0:08:17

0:08:17

0:02:44

0:02:44

0:05:09

0:05:09

0:08:33

0:08:33

0:01:50

0:01:50

0:10:28

0:10:28

0:01:39

0:01:39

0:02:33

0:02:33

0:00:53

0:00:53

0:07:03

0:07:03

0:01:36

0:01:36

0:06:34

0:06:34

0:42:21

0:42:21

0:02:27

0:02:27

0:01:33

0:01:33

0:13:36

0:13:36

0:04:20

0:04:20

0:00:43

0:00:43

0:18:32

0:18:32

0:01:47

0:01:47

0:04:12

0:04:12

0:09:43

0:09:43

0:00:47

0:00:47