filmov

tv

Watertight 3D Printing

Показать описание

Today, we’re going to figure out how to make watertight 3D prints!

————————————————————————————————

————————————————————————————————

Are 3D prints water tight?

Making 3D prints actually waterproof

Is it possible to make 3D prints watertight?

Mastering Watertight 3D Prints: The Ultimate Guide

Are 3D printed parts (and bottles) watertight? 💦 #nexa3d #xip #mSLA #watertight #3dprinting

Watertight 3D Printing

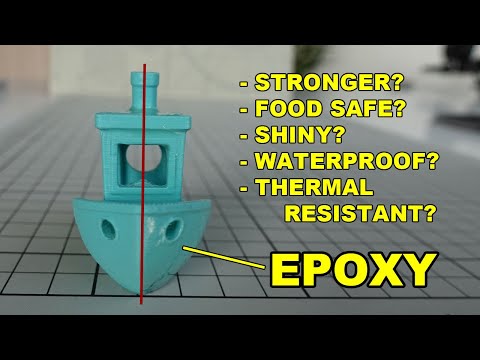

3D printed objects coated with epoxy resin - but why?

Bully Liner coating can improve your 3D prints dramatically

Magnum+ vs. Prime: Which Hotend Is Right for Your 3D Printer?

Watertight 3D Prints and Calculating Volume in Fusion 360 - Refil Bottle Tweaks

💧 Watertight PLA Vases - Waterproof 3D Print - Watertight 3D Printing

Is this 3D Printable Storage Box Watertight? #shorts

3d printing planters is AWESOME. Here's why.

This Box Keeps Out Water Without a Seal | Design for Mass Production 3D Printing

Water-Resistant Vents for Industrial Applications | Design for Mass Production 3D Printing

Does 3D printing work at 40 m depth underwater?

Episode 15 - Watertight 3d prints

Can 3D Printed Parts be Waterproof?

Can you 3D Print a Water Bottle? | Design for Mass Production 3D Printing

Designing a Watertight 3D Printed Pipe #3dprinted #3dprinter #diy

Gas tight 3D-prints

add:north - How to make 3D-prints watertight

I 3D Printed a Form Fitted Rugged Box | Here's How I Did It.

8 slicer settings to waterproof your 3D prints

Комментарии

0:05:39

0:05:39

0:16:05

0:16:05

0:01:00

0:01:00

0:11:51

0:11:51

0:00:38

0:00:38

0:04:35

0:04:35

0:12:19

0:12:19

0:17:40

0:17:40

0:11:03

0:11:03

0:11:44

0:11:44

0:01:44

0:01:44

0:00:55

0:00:55

0:04:21

0:04:21

0:04:30

0:04:30

0:09:55

0:09:55

0:10:49

0:10:49

0:08:13

0:08:13

0:03:16

0:03:16

0:09:07

0:09:07

0:00:21

0:00:21

0:08:30

0:08:30

0:01:00

0:01:00

0:10:46

0:10:46

0:00:55

0:00:55