filmov

tv

PRECISION SPINDLE METROLOGY Pt. 3: Measuring Error Motion

Показать описание

In which we start to get into how to actually measure spindle errors and process the data. Next time, we get to go into error separation.

PRECISION SPINDLE METROLOGY Pt. 3: Measuring Error Motion

PRECISION SPINDLE METROLOGY Pt. 1: Fundamental Concepts

Drew's Views - Axis of Rotation Metrology

Machine Spindle Diagnostics and Maintenance - Spindle Analyzer by Automated Precision Inc.

Precision Metrology- Two footed twist gage and Hertzian contact stresses

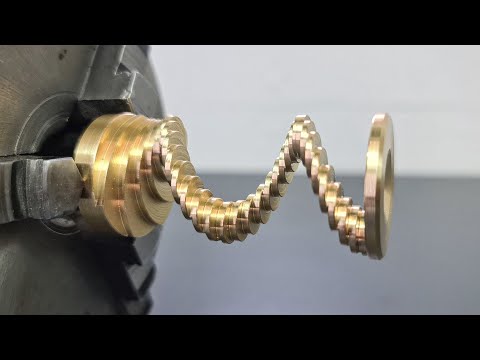

Making a Crazy Part on the Lathe - Manual Machining

MAKING ULTRA PRECISION TOOLROOM SPINDLES #1

Incremental Encoder (Shaft Encoder)- how it works

How to Identify Thread Pitch and Size | Tech Tips | Swagelok [2020]

DIY Spindle square - Part 3, Pimp it out

HaasTooling Precision Machinist's Level - Haas Automation, Inc.

high precision ID micrometer Mitutoyo #cncmachine #manufacturing

How to Measure FLATNESS Perfectly with Jack Stands

How to Measure Parallelism in Machining/Manufacturing

M3-L3, METROLOGY & INSTRUMENTATION, MODULE 3, LEC-3

OFFSET SETTING IN MILLING MACHINE #vmc #mechanicalengineering

Measuring Brass Parts w/ a Tube Micrometer

How to Read a Metric Vernier Caliper

Dial and Digital Height Gauges Now on HaasTooling.com - Haas Metrology

vhf dental machines – Part 1/3 Machine Accuracy and Calibration

Simple metrology for a semi precision angle plate

Measuring all 6 Degrees of Freedom - XD Laser by Automated Precision Inc.

Roundness Measuring Instrument I How To Adjust Centering and Leveling on Surtronic R150

Portable CNC Rotary Calibration System - Swivelcheck by Automated Precision Inc.

Комментарии

0:23:45

0:23:45

0:29:40

0:29:40

0:02:42

0:02:42

0:02:35

0:02:35

0:12:53

0:12:53

0:04:15

0:04:15

0:30:37

0:30:37

0:01:17

0:01:17

0:03:24

0:03:24

0:30:15

0:30:15

0:06:34

0:06:34

0:00:27

0:00:27

0:08:31

0:08:31

0:00:47

0:00:47

0:23:47

0:23:47

0:00:16

0:00:16

0:00:30

0:00:30

0:07:02

0:07:02

0:15:39

0:15:39

0:05:25

0:05:25

0:09:00

0:09:00

0:03:22

0:03:22

0:01:12

0:01:12

0:03:56

0:03:56