filmov

tv

Ultrasonic Flow Meter Explained | Working Principles

Показать описание

▶ You can read the full post here

⌚Timestamps:

00:00 - Intro

00:54 - Ultrasonic flow meter

01:20 - Physical principles

02:00 - Mechanical principles

02:49 - Electrical principles

03:16 - Dynamics

05:16 - Design considerations

06:40 - Applications

=============================

There are many types of process flow meters:

- Coriolis mass flow meters;

- Positive displacement flow meters, such as turbine meters;

- Volumetric flow meters, like the ultrasonic flow meter, just to name a few.

Each type of flow meter operates on different physical, mechanical, and electrical principles.

In this video, we will explore the working principles for Ultrasonic flow meters. We will demonstrate how a simple physical property, sound, can be used to measure the rate of flow of a fluid moving in a pipe.

Ultrasonic flow meters measure the volumetric flow of the fluid, that is, the number of gallons or liters per unit time.

Ultrasonic flow meters require the use and understanding of some basic physical, mechanical and electrical principles that allow ultrasonic flow meters to accurately measure flow rate over a wide range of flow conditions.

Here are a few examples of using basic physical, mechanical, and electrical principles to measure the flow rate using an ultrasonic flow meter:

1) When fluid flows through a pipe, it flows in one direction at a velocity that is influenced by many factors, such as temperature, pressure, fluid viscosity, and pipe size.

2) Sound waves move through a fluid based on the transmission of vibrations through the fluid. These mechanical oscillations between molecules of the flowing fluid are passed to adjacent molecules, thereby transferring the wave to those adjacent molecules.

3) An ultrasonic flow meter generates sound waves using a rapidly vibrating piezoelectric crystal. These special ceramic crystals deform when an electric current is applied. By rapidly changing the electrical signal, the crystal will deform in one direction, and then in the other, causing a high-frequency wave to be generated.

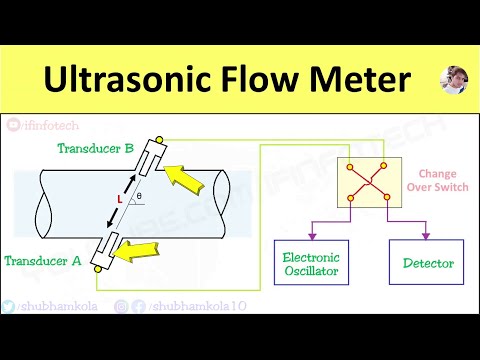

An ultrasonic flow meter consists of at least one sensor and transducer pair. Each member of the pair can act both as a transmitter and a receiver.

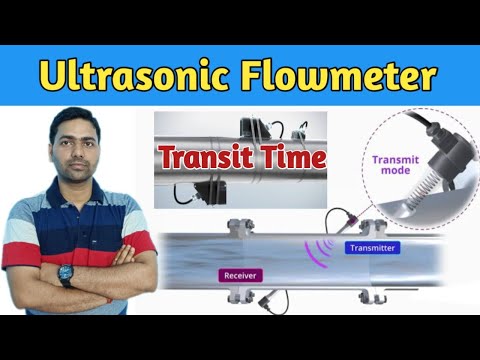

- When in transmit mode, an oscillating electrical current creates a vibration in the piezoelectric crystal, and an ultrasonic wave is sent through the flowing fluid.

- When in receive mode, an ultrasonic wave passing through the fluid creates vibration in the piezoelectric crystal, and an electrical impulse is generated.

A pulse that travels from the upstream element to the downstream element, or with the flow, takes less time to make the trip than the pulse returning in the opposite direction, or against the flow. The difference in this time of flight between the two pulses is directly proportional to the flow velocity.

Since the volumetric flow rate is equal to velocity times the cross-sectional area of the pipe, which is fixed at the flow meter, this measurement yields the flow rate. This type of ultrasonic flow meter is appropriately named a time of flight flow meter.

In order to eliminate differences in the flow profile across the pipe, additional pairs of sensors are added to ensure an accurate measurement. Each pair of transmitter and receiver forms what is called a chord.

There are many different ways that the sensors are mounted in a time of flight ultrasonic flow meter.

- The sound wave pulses can travel directly from transmitter to receiver or the pipe wall can be used to reflect the sound waves.

- The sensors can be wetted, or built into the wall of the flow meter such that the sensors contact the fluid. Or the sensors can be strapped to the exterior of the pipe, where the sensors do not contact the fluid. The non-contact sensors are not quite as accurate.

Ultrasonic flow meters are an excellent choice for high-pressure, high-flow applications.

=============================

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #UltrasonicFlowMeter #Sensor

Комментарии

0:08:23

0:08:23

0:01:16

0:01:16

0:05:55

0:05:55

0:03:21

0:03:21

0:03:11

0:03:11

0:04:12

0:04:12

0:03:21

0:03:21

0:59:55

0:59:55

0:01:42

0:01:42

0:03:31

0:03:31

0:39:50

0:39:50

0:08:05

0:08:05

0:01:34

0:01:34

0:11:51

0:11:51

0:01:35

0:01:35

0:06:13

0:06:13

0:06:59

0:06:59

0:05:43

0:05:43

0:03:38

0:03:38

0:03:04

0:03:04

0:04:37

0:04:37

0:02:59

0:02:59

0:12:46

0:12:46

0:00:16

0:00:16