filmov

tv

GAME OVER!? - A.I. Designs New ELECTRIC Motor

Показать описание

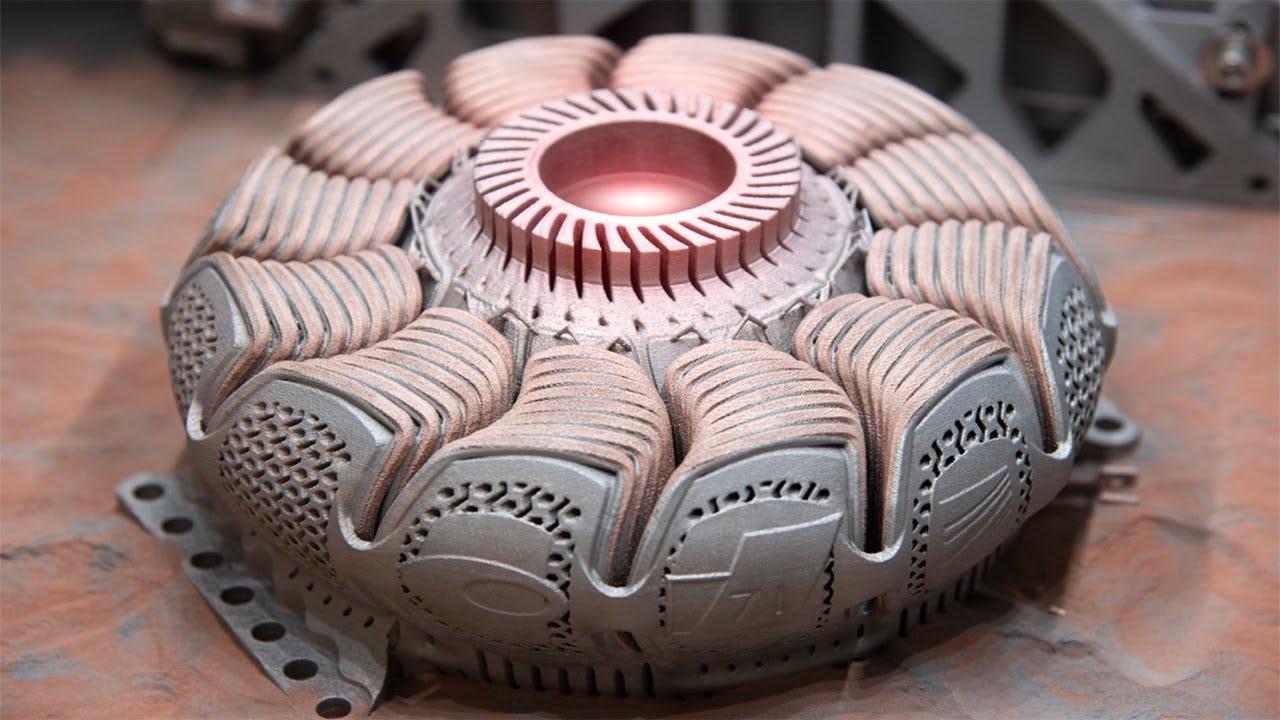

PicoGK forms the basis for all of the company’s computational engineering models. It has lead to the development of a completely new electric motor that is entirely 3D printed through AM. But is this the future of motor design?

Sources & Credits:

Sources & Credits:

GAME OVER!? - A.I. Designs New ELECTRIC Motor

GAME OVER - A.I. Designs CRAZY New ROCKET Engine

GAME OVER - A.I. Designs CRAZY Rocket of the FUTURE

Revolutionary A.I. Rocket Engine: Game Over for Traditional Designs!

Game Design as Narrative Architecture | The 5 Types of Spaces in Games

Cars & School Bus vs Giant Hammer #16 - BeamNG.Drive

Max Design pro game over Bootleg

Tesla VS. $6 000 000 Cars #shorts

Atari 7800+ FULL REVIEW | New Console, CX-78+, & Crystal Quest

Minecraft Battle Tank🪖 (World's Smallest Violin) #shorts #minecraft

Dogs teach us love in its purest form EP-9😰

THEY FLOODED MY BASE?!

Bringing History and Depth to A City

Game changing design trick! 🤯 #procreate #design

Game design mechanics for our indie game #indiegame #devlog

Are Lives Outdated Game Design?

The Simulation Fallacy in Game Design

Game over 😞 #trending #behlbrothers #shorts

August - FEAST or FAMINE Champs Are Great Game Design (SAMIRA)

Ramped Up Action: Spider-Man's Bike Stunts in GTA 5 | Rampage: Spider-Man's Daring Bike St...

5 Game Design Principles Every Developer Should Know

Cars vs Chained Hydraulic Crush #8 - BeamNG.Drive

Intentional Game Design/Game Over Films (1998) 'Comic's Revenge'

Simon Belmont’s Costume Origins in Smash Ultimate

Комментарии

0:06:03

0:06:03

0:05:26

0:05:26

0:08:42

0:08:42

0:08:38

0:08:38

0:10:54

0:10:54

0:00:21

0:00:21

0:01:41

0:01:41

0:01:00

0:01:00

0:19:50

0:19:50

0:00:38

0:00:38

0:00:28

0:00:28

0:00:48

0:00:48

0:01:00

0:01:00

0:00:46

0:00:46

0:00:20

0:00:20

0:08:45

0:08:45

0:12:52

0:12:52

0:01:00

0:01:00

0:01:00

0:01:00

0:00:17

0:00:17

0:00:57

0:00:57

0:00:14

0:00:14

0:00:18

0:00:18

0:00:55

0:00:55