filmov

tv

Electronics - Tapping and repairing PCB traces.

Показать описание

Demonstrating the method I use to tap a PCB trace, and then how to repair a broken trace. My hands are not as steady as they used to be, but I think I get the idea across OK.

Yes, I know, it' better to tap at solder pads, but that's not what the viewer asked about. :-)

Discuss this and other videos on Facebook:

Yes, I know, it' better to tap at solder pads, but that's not what the viewer asked about. :-)

Discuss this and other videos on Facebook:

Electronics - Tapping and repairing PCB traces.

tap in for all you electronic repairs and modifications needs I also can do HDMI mod on most console

#𝙈𝙀𝘾𝙃𝘼𝙉𝙄𝘾® PACK high temperature resistant electronic tap

Water Tap Repair Tips And Tricks | Electronic Hints #diy #reels #shorts

Wireless Charger | Theory & Homemade Circuit

How a Fuse Tap Works #FuseTap #Wiring #Electronics

How the junction box terminals tapping #terminal #accessories #machinery #electricbox #electronics

nostalgic song | cassette tap | Panasonic #electronic #repair #electric #automobile #audioequipment

Parkside Tap Die Set - should you buy ?

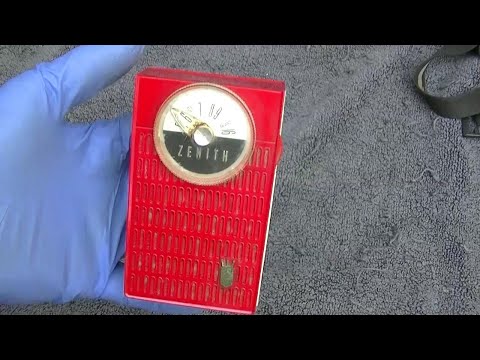

Repairing 2 Vintage Transistor Radios

Lenovo Lap Tap Keyboard #electronic #laptop #repairing

JBL MPX600 Amplifier Repair : Can A Blown Channel Have A Short If The Fuses Are OK?

How to Replace Thermal Fuses: Repair Tips from the Fixit Clinic

tap licking #tech #technology #electrical #innovative #electronic #engineering

GARBAGE DISPOSAL NOT WORKING?! Try These Easy Fixes! (3 Sink Disposal Repairs...More Tips + Tricks!)

emergency tap for charger on #tutorial #electrical #electronic #youtube #youtubeshorts #shorts #s

How to make a terminal tapping for junction boxes #machinery #terminal #electronics #electricbox

How to use the Minerva 4-in-1 Electronic Tap

Connecting multiple electronics laboratory power supplies in series with center tap UPDATED 2021

5 Mistakes Everyone Makes Changing Sockets ❌

SNES Repair: Broken Traces & Burn In Test Socket (Part 1)

Smart Water Tap: Electronics For You DIY Project

How to make automatic sensor tap / sk projects electronic.

6 Easy Ways to Remove Rust from Tools & Hardware | The Home Depot

Комментарии

0:10:54

0:10:54

0:00:25

0:00:25

0:00:27

0:00:27

0:00:51

0:00:51

0:14:08

0:14:08

0:01:01

0:01:01

0:00:14

0:00:14

0:00:51

0:00:51

0:02:37

0:02:37

0:46:40

0:46:40

0:00:38

0:00:38

1:16:04

1:16:04

0:02:42

0:02:42

0:00:16

0:00:16

0:05:24

0:05:24

0:00:20

0:00:20

0:00:17

0:00:17

0:01:47

0:01:47

0:07:46

0:07:46

0:11:44

0:11:44

0:50:50

0:50:50

0:01:22

0:01:22

0:04:46

0:04:46

0:01:59

0:01:59