filmov

tv

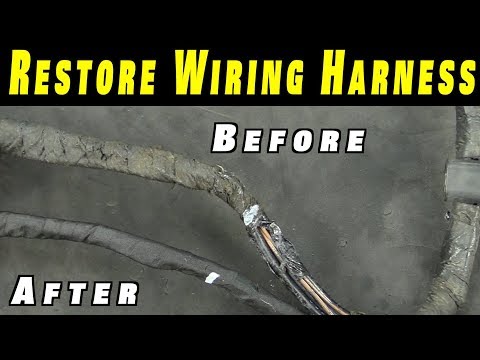

Fixing The Wiring In The Free Abandoned Airplane !

Показать описание

Huge step done for the Free Abandoned Airplane project today as we fix the wiring issues in the new 402 wings. After removing all four wing harnesses from the 401 and 402 wings, we inspect and clean everything and then reinstall the best two harnesses into the new wings. Bar connecting it all to power and checking if it works, the wing wiring is now all taken care of.

Rebuild Rescue Videos:

FREE Abandoned Airplane... If I Can Start It! Ep1

Taking Our FREE Abandoned Airplane Home! Ep2

He's Trying To STEAL Our FREE Abandoned Airplane ! Ep3

Will Our FREE Abandoned Airplane Finally Start? Ep4

Is The FREE Abandoned Airplane Finally Ours ?! Ep5

Did We Ruin The FREE Abandoned Airplane Engine ? Ep6

Our FREE Abandoned Airplane Gets Its First Wash In 17 Years ! Ep7

Will Engine #2 Ever Run Again On Our FREE Abandoned Airplane !? Ep8

Please support the 401 project with a donation to our gofundme. Anything you can offer is greatly appreciated!

Grab yourself some Rebuild Rescue Merch!

CHECK OUT THIS LINK..... its free...

Contact info

#FreePlane #AbandonedPlane #RebuildRescue

Rebuild Rescue Videos:

FREE Abandoned Airplane... If I Can Start It! Ep1

Taking Our FREE Abandoned Airplane Home! Ep2

He's Trying To STEAL Our FREE Abandoned Airplane ! Ep3

Will Our FREE Abandoned Airplane Finally Start? Ep4

Is The FREE Abandoned Airplane Finally Ours ?! Ep5

Did We Ruin The FREE Abandoned Airplane Engine ? Ep6

Our FREE Abandoned Airplane Gets Its First Wash In 17 Years ! Ep7

Will Engine #2 Ever Run Again On Our FREE Abandoned Airplane !? Ep8

Please support the 401 project with a donation to our gofundme. Anything you can offer is greatly appreciated!

Grab yourself some Rebuild Rescue Merch!

CHECK OUT THIS LINK..... its free...

Contact info

#FreePlane #AbandonedPlane #RebuildRescue

Комментарии

0:33:25

0:33:25

0:10:33

0:10:33

0:08:50

0:08:50

0:08:36

0:08:36

0:05:02

0:05:02

0:11:06

0:11:06

0:02:18

0:02:18

0:09:01

0:09:01

0:01:00

0:01:00

0:49:01

0:49:01

0:12:00

0:12:00

0:04:27

0:04:27

0:06:58

0:06:58

0:04:35

0:04:35

0:42:51

0:42:51

0:05:12

0:05:12

0:07:11

0:07:11

0:07:11

0:07:11

0:07:29

0:07:29

0:28:42

0:28:42

0:06:06

0:06:06

0:23:40

0:23:40

0:18:12

0:18:12

0:09:30

0:09:30