filmov

tv

5 Tips - Building Speaker Boxes

Показать описание

My personal advice for building speaker boxes. Make sure to share your own tips.

Music Credits:

Licensed under Creative Commons: By Attribution 4.0 License

Music Credits:

Licensed under Creative Commons: By Attribution 4.0 License

5 Tips - Building Speaker Boxes

Building EXCEPTIONAL speakers using MODERN TECHNIQUES

How to Pick The BEST Drivers For Your DIY Speaker Project

How to design speaker enclosure, basics | 2 things to get right in enclosure design

Is a Deep Speaker Box Better? Tested with Surprising Results

Passive Radiators Explained. Basic Speaker Building Techniques

How To Make Speaker crossover || Capacitor, Resistor, Coil, Lpad Fonction

✅ Best Dolby Atmos Soundbars (Top 5) – Ultimate Guide & Reviews

5 Tools Every Speaker Builder Needs

How To Clean Speaker of Mobile 𝕎ith 𝕊ound || Speaker clean redmi 9 power | Dust remove 2022

YES! You CAN build $5000 HiFi Speakers for UNDER $500 DIY vs HiFi

Best Stuffing for Speakers Tested - Unexpected Results

The BEST Shape for a Speaker REVEALED

Turn Anything Into A Speaker😱 #travelhack

Diy Bass Booster Speaker | 3 Way Hi Fi Speaker crossover

How to speak English like a native speaker

Easy DIY Speaker Enclosure Design Using Free Software In 5 Steps | (How To Design Your Own Speakers)

Make any speakers sound better for less than $1

Are Your Speakers Loud Enough? Use These Formulas To Find Out...

How to Make an $80 Speaker Beat $1,000 Speakers

How to make speaker louder and clear bass

High Bass Speakers

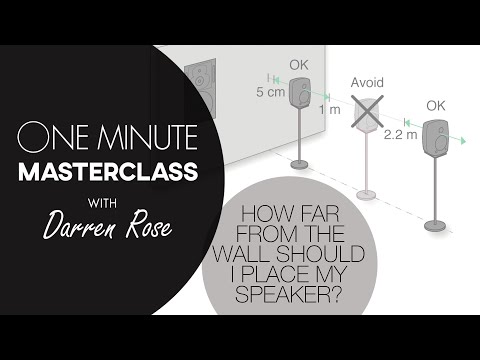

How far from the wall should I place my speaker? | Episode 10 | One Minute Masterclass Season 2

cara membuat speaker bluetooth portable #speakerportable #sound #kreatiftv

Комментарии

0:09:43

0:09:43

0:22:20

0:22:20

0:14:49

0:14:49

0:05:01

0:05:01

0:06:04

0:06:04

0:02:58

0:02:58

0:08:02

0:08:02

0:08:06

0:08:06

0:09:59

0:09:59

0:00:27

0:00:27

0:06:27

0:06:27

0:10:32

0:10:32

0:09:41

0:09:41

0:00:15

0:00:15

0:01:52

0:01:52

0:00:17

0:00:17

0:22:54

0:22:54

0:00:25

0:00:25

0:05:21

0:05:21

0:18:49

0:18:49

0:01:40

0:01:40

0:00:28

0:00:28

0:01:12

0:01:12

0:00:32

0:00:32