filmov

tv

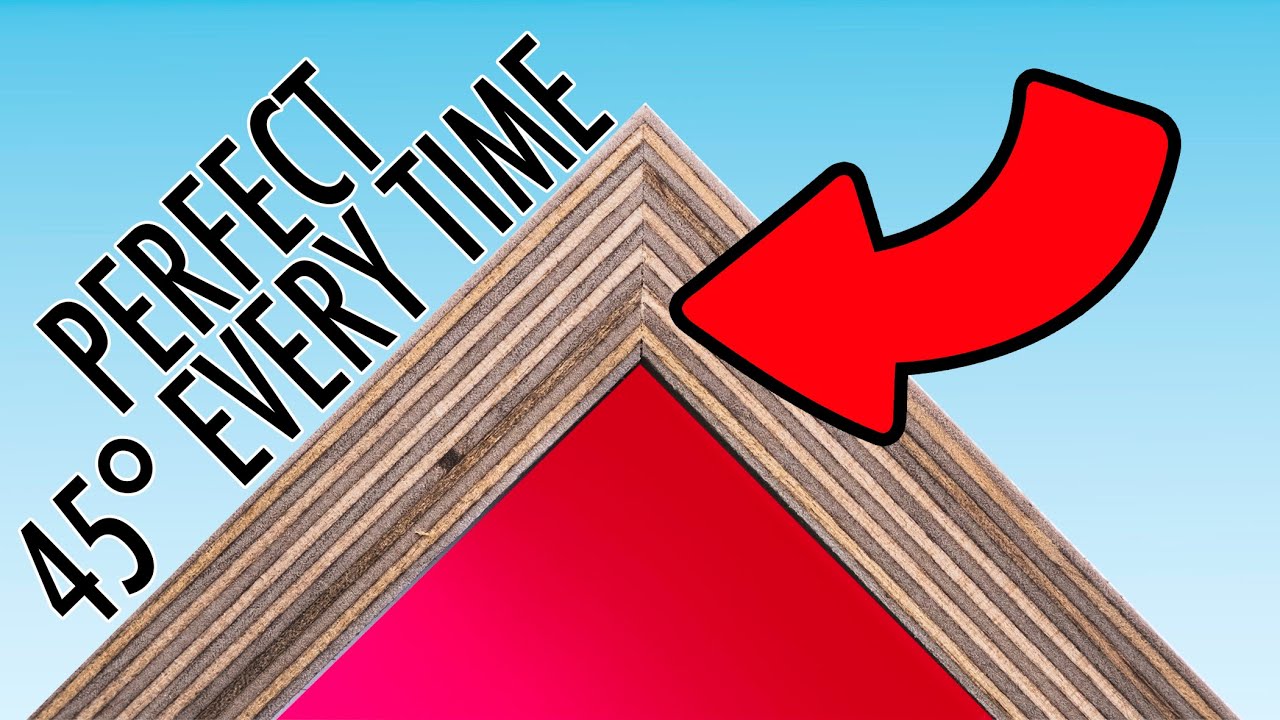

It's like cheating

Показать описание

Why is it that the miters sometimes looks awful even though you've done everything to the book? This might be the answer your looking for.

Above links are affiliate links, it means I may get a small percentage at no extra cost to you.

SOCIAL:

Above links are affiliate links, it means I may get a small percentage at no extra cost to you.

SOCIAL:

It was Supposed to be like Cheating

This girl Caught Her Husband Cheating On Her wedding day 😭❤️ #shorts

Bridesmaid gets caught cheating with groom!😱 #Shorts

4 signs she’s cheating on you

A present for your CHEATING HUSBAND😳🎁 #shorts #couples

Cheating isn’t real

Boyfriend catches Girlfriend cheating | Heart Broken | Sad status

cheating girlfriend begs for forgiveness..

catching girlfriend cheating.. #jvke ‘this is what heartbreak feels like’

Girlfriend Cheating On Boyfriend 😓💔 Heart Broken 😖 || Full Screen || Whatsapp Status #shorts...

Top signs that a woman is cheating

Flying the BRAND NEW Cessna 182 is like CHEATING!

How To Get Someone To Tell The Truth About Cheating

Girl crashed her boyfriend's car because he's cheating...😰 #medical #md

This is like cheating... War Robots #warrobots

This is part of the game, but it feels like cheating...

If You Think He's Cheating on You, Watch This

2 best cheating wife movies to watch tonight

Two Married People CAUGHT Cheating!

This new Widowmaker skin is like CHEATING in Overwatch

5 Major Signs She's Cheating (or Losing Interest!) | Courtney Ryan

CHEATING HUSBAND didn't expect THIS to REVEAL HIM | @DramatizeMe

Why cheating men aren’t bad

Spies Like Us (1985) - Cheating on the Exam Scene (1/8) | Movieclips

Комментарии

0:11:38

0:11:38

0:00:19

0:00:19

0:01:00

0:01:00

0:01:00

0:01:00

0:01:00

0:01:00

0:00:41

0:00:41

0:00:43

0:00:43

0:08:43

0:08:43

0:01:01

0:01:01

0:00:31

0:00:31

0:01:27

0:01:27

0:18:51

0:18:51

0:07:12

0:07:12

0:00:58

0:00:58

0:00:59

0:00:59

0:00:32

0:00:32

0:04:45

0:04:45

0:02:55

0:02:55

0:01:00

0:01:00

0:11:06

0:11:06

0:10:21

0:10:21

0:10:22

0:10:22

0:00:53

0:00:53

0:03:15

0:03:15