filmov

tv

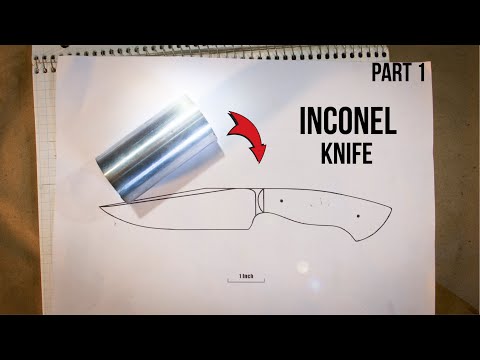

Making A Nitinol Knife. Part 1: Forging Nitinol

Показать описание

Looks like I've been sent original US Navy nitinol and asked to make a 7" blade! I got to squish it out into a usable piece and forge it into a knife! I've been hiding a bow and shoes in my videos in honor of my family, have you noticed?

Starbond Knife Handle Video Tutorial

Special thanks to Patreon supporters Matt Bartlett, Zee Axis and Joe Chestnut, Dan Helfond!

This video content is copyrighted and may not be reused, published or distributed without my express, written permission.

Starbond Knife Handle Video Tutorial

Special thanks to Patreon supporters Matt Bartlett, Zee Axis and Joe Chestnut, Dan Helfond!

This video content is copyrighted and may not be reused, published or distributed without my express, written permission.

Making A Nitinol Knife. Part 1: Forging Nitinol

Making A Nitinol Knife. Part 2: Finishing The Knives!

Making a SUPER ALLOY knife! Can I do it??? Part 3

custom designed nitinol shape memory alloy rolling circle

Making a SUPER ALLOY knife! Can I do it???

nitinol shape memory alloy tube

Comparing $300 Chinese war swords with $30 machete. #shorts #knife

Nitinol alloy | Nitinol metal | astm f2063 | BAOJI HIGHSTAR TITANIUM

Magic props nitinol fork

The rolling mill I built is WORKING!!

We built self healing Wolverine claws! 😨 #marvel #wolverine #engineering #science #superhero

Shape Memory Alloys Can Lift Rocks

Nitinol Metal is insane! #shorts

METAL 3D printed Chainmail🤯

Strider 60 NiTiNOL PM SMF

Nitinol wire demonstration (UOM)

HYDRAULIC PRESS VS NITINOL, METAL WITH MEMORY | THE EXPERIMENT IDEAS

Nitinol tube, memory titanium

The Metal That Remembers - Nitinol

Forging A Ball Bearing Nakiri

Biting through metal (Indium)

Forging a Mosaic Damascus Blade Part 2

Shape Memory Alloy Nitinol | Amazing shape memory effect | #shorts #Nitinol #experiments #Titanium

Ultrafast Laser Cutting of Low Mass Superelastic Nitinol Parts

Комментарии

0:16:23

0:16:23

0:13:10

0:13:10

0:09:46

0:09:46

0:00:19

0:00:19

0:10:49

0:10:49

0:00:13

0:00:13

0:00:32

0:00:32

0:00:55

0:00:55

0:00:25

0:00:25

0:00:19

0:00:19

0:00:15

0:00:15

0:01:00

0:01:00

0:00:12

0:00:12

0:00:33

0:00:33

0:01:59

0:01:59

0:01:51

0:01:51

0:02:02

0:02:02

0:00:06

0:00:06

0:05:11

0:05:11

0:15:06

0:15:06

0:01:01

0:01:01

0:15:10

0:15:10

0:01:10

0:01:10

0:31:22

0:31:22