filmov

tv

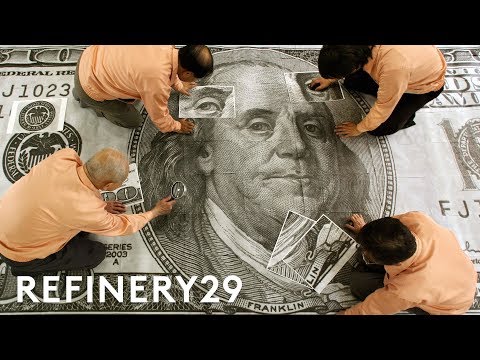

HOW IT'S MADE: Money (In Factories)

Показать описание

HOW IT'S MADE: Money (In Factories)

Money is something that most of us deal with every day. In present days most things are driven by money. Although we are in an era where digital currency has taken over the world, physical money still remains an important part of our day-to-day life. Ever wondered how these physical commodities are made?

Today on How It’s Made we will take you through the journey of manufacturing undoubtedly the most wanted product on Earth, Money. Stay with us till the end of the video to know everything about physical currency notes.

A Brief History of Money

To start with, let’s travel back about 1400 years to the 7th century when evidence of the first banknote-like instrument was seen in China, during this era. But the true paper money was introduced almost 400 years later, in the 11th century during the Song Dynasty in China.

Explorers and merchants from the West took this concept and introduced it to Europe and other parts of the world and thus, paper money started gaining popularity. By the end of the 18th century, almost the whole world had adopted the concept of paper money in place of exchanging metals for trade.

Till now we have seen numerous iterations and additions making the process more and more complicated to ensure security, and prevent forgery. Did you know that almost all countries have their own unique forms of security for their notes?

Just like earning money is not a very easy job, the same goes for making money. Printing money in the factory is not a simple task at all! It includes a long list of processes that are done by both humans and robots.

Material

Most currency notes are made from paper but modern-day currencies also include polymer banknotes. Paper money is not made of simple paper that’s derived from wood pulp, but it is made of cotton paper mixed with about twenty percent of Linen, abaca, or some other textile material to make it much more resilient and resistant to wear and tear.

To add more strength to the currency notes they are infused with polyvinyl alcohol or gelatin instead of water, which is used in common paper. Polymer notes were in fact first introduced as a material for currency all the way back in the eighties.

But in its early days’ polymer notes saw various problems such as fading of ink etc. and could not be continued. A few years later, after a significant amount of research and development, Australia came up with polymer banknotes and this time without any problem.

Since then more countries have started using polymer banknotes. Did you know that in the early 2000s, it came to light that in some cases the cost of manufacturing these polymer notes was actually more expensive than the value of the currency itself?

Interesting, isn’t it?

Now, let’s delve into the manufacturing process!

Step 1: Design and Engraving

The process of making money doesn’t start only with the raw material but from the design stage itself. In the United States, these notes are hand-designed by extremely talented artists and designers and the master dife is hand-cut by engravers.

Yes, you heard it right, these notes are hand-cut! Engravers cut the master die on soft steel, by hand, using various tools. Every time the Treasurer of the country changes, their signatures are engraved by hand using various references.

Step 2: Creating the Master Printing Plate

Once the master plate is done, it is then inspected, heated and a thin plastic sheet is pressed into it to get a raised impression of the full design and then the die is kept in the storage.

Using the plastic alto further processes are followed to manufacture the master printing plate which is used for the printing purpose. Different countries have unique processes for their currency designs which combine various elements to increase security.

Step 3: Paper Manufacturing

As we already mentioned, banknote papers are not common writing papers. Different countries manufacture their banknote papers in different ways. Mixing cotton pulp with other fiber materials is in most cases an in-house paper manufacturing process.

During this process of addition of security, threads come into the picture. Security threads are the ribbon-like feature that is very commonly seen on most paper currencies. Its main purpose is to protect the note from counterfeiting.

Usually, it runs vertically and is woven into the paper. So when seen from one side it is seen only at some places but when it’s held against light a continuous line is seen. These security threads can be made of different materials starting from metal to plastic and also come in various widths and colors.

These embedded threads sometimes even have micro printings and also features such as fluorescing under UltraViolet light etc. Security threads and watermarks on the banknote during the paper manufacturing process are the two most common features that help the general public recognize original currency notes.

#howitsmade #factory #printing

Money is something that most of us deal with every day. In present days most things are driven by money. Although we are in an era where digital currency has taken over the world, physical money still remains an important part of our day-to-day life. Ever wondered how these physical commodities are made?

Today on How It’s Made we will take you through the journey of manufacturing undoubtedly the most wanted product on Earth, Money. Stay with us till the end of the video to know everything about physical currency notes.

A Brief History of Money

To start with, let’s travel back about 1400 years to the 7th century when evidence of the first banknote-like instrument was seen in China, during this era. But the true paper money was introduced almost 400 years later, in the 11th century during the Song Dynasty in China.

Explorers and merchants from the West took this concept and introduced it to Europe and other parts of the world and thus, paper money started gaining popularity. By the end of the 18th century, almost the whole world had adopted the concept of paper money in place of exchanging metals for trade.

Till now we have seen numerous iterations and additions making the process more and more complicated to ensure security, and prevent forgery. Did you know that almost all countries have their own unique forms of security for their notes?

Just like earning money is not a very easy job, the same goes for making money. Printing money in the factory is not a simple task at all! It includes a long list of processes that are done by both humans and robots.

Material

Most currency notes are made from paper but modern-day currencies also include polymer banknotes. Paper money is not made of simple paper that’s derived from wood pulp, but it is made of cotton paper mixed with about twenty percent of Linen, abaca, or some other textile material to make it much more resilient and resistant to wear and tear.

To add more strength to the currency notes they are infused with polyvinyl alcohol or gelatin instead of water, which is used in common paper. Polymer notes were in fact first introduced as a material for currency all the way back in the eighties.

But in its early days’ polymer notes saw various problems such as fading of ink etc. and could not be continued. A few years later, after a significant amount of research and development, Australia came up with polymer banknotes and this time without any problem.

Since then more countries have started using polymer banknotes. Did you know that in the early 2000s, it came to light that in some cases the cost of manufacturing these polymer notes was actually more expensive than the value of the currency itself?

Interesting, isn’t it?

Now, let’s delve into the manufacturing process!

Step 1: Design and Engraving

The process of making money doesn’t start only with the raw material but from the design stage itself. In the United States, these notes are hand-designed by extremely talented artists and designers and the master dife is hand-cut by engravers.

Yes, you heard it right, these notes are hand-cut! Engravers cut the master die on soft steel, by hand, using various tools. Every time the Treasurer of the country changes, their signatures are engraved by hand using various references.

Step 2: Creating the Master Printing Plate

Once the master plate is done, it is then inspected, heated and a thin plastic sheet is pressed into it to get a raised impression of the full design and then the die is kept in the storage.

Using the plastic alto further processes are followed to manufacture the master printing plate which is used for the printing purpose. Different countries have unique processes for their currency designs which combine various elements to increase security.

Step 3: Paper Manufacturing

As we already mentioned, banknote papers are not common writing papers. Different countries manufacture their banknote papers in different ways. Mixing cotton pulp with other fiber materials is in most cases an in-house paper manufacturing process.

During this process of addition of security, threads come into the picture. Security threads are the ribbon-like feature that is very commonly seen on most paper currencies. Its main purpose is to protect the note from counterfeiting.

Usually, it runs vertically and is woven into the paper. So when seen from one side it is seen only at some places but when it’s held against light a continuous line is seen. These security threads can be made of different materials starting from metal to plastic and also come in various widths and colors.

These embedded threads sometimes even have micro printings and also features such as fluorescing under UltraViolet light etc. Security threads and watermarks on the banknote during the paper manufacturing process are the two most common features that help the general public recognize original currency notes.

#howitsmade #factory #printing

Комментарии

0:08:40

0:08:40

0:12:26

0:12:26

0:05:39

0:05:39

0:08:06

0:08:06

0:08:04

0:08:04

0:06:10

0:06:10

0:10:10

0:10:10

0:25:37

0:25:37

0:06:24

0:06:24

0:06:22

0:06:22

0:12:00

0:12:00

0:07:08

0:07:08

0:11:03

0:11:03

0:07:46

0:07:46

0:09:28

0:09:28

0:14:20

0:14:20

0:10:43

0:10:43

0:05:33

0:05:33

0:11:06

0:11:06

0:09:24

0:09:24

0:05:30

0:05:30

0:13:28

0:13:28

0:06:18

0:06:18

0:09:07

0:09:07