filmov

tv

Calculating and setting up a taper part #1

Показать описание

Making a balancing mandrel for grinding arbors.

Calculating and setting up a taper part #1

Calculating and setting up a taper part #2

Setting up a VASP calculation - Beginners

ALEKS: Setting up a reaction table for a pH calculation with a common ion

Setting up a VASP calculation

ALEKS: Setting up a reaction table for a pH calculation with a common ion

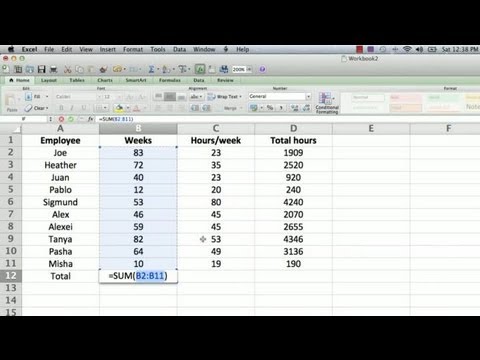

How to Make a Totaling Column Formula in Excel : Using Microsoft Excel

Aleks Setting up a reaction table for a pH calculation with a common ion

How Do You Set Up Tax Rates? | Step-by-Step Guide

Setting up and Performing a Titration

Calculate the cost of setting up your business in the UAE with our cost calculator | Decisive Zone

How to Calculate the RIGHT Lot Size for Forex Trading 📈

How to calculate Capacity of Starting capacitor in single phase motors | starting capacitor value

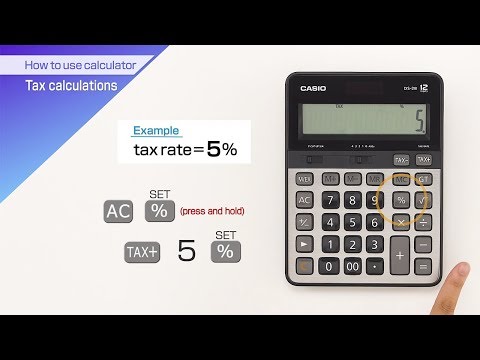

CASIO【How to use calculator Tax calculations】

How to do Square-up Diagonal Calculations without Formulas | Construction Master 5

Introduction to Density Functional Theory [Part Two] Setting up a VASP Calculation

How To...Calculate the Confidence Interval for a Sample

Calculating Mechanical Advantage when setting up a climbing haul

Setting up a reaction table for a pH calculation with a common ion

17.6b Setting up a reaction table for a pH calculation with a common ion

ATR - Average True Range indicator EXPLAINED in less than 2 minutes

How to Set Up Double Integrals

IV Drip Flow Rates Drop Factor gtts/minute Dosage Calculations Nursing | NCLEX Review

Setting up a calculated field in Access

Комментарии

0:18:25

0:18:25

0:19:34

0:19:34

0:02:40

0:02:40

0:02:05

0:02:05

0:02:44

0:02:44

0:01:51

0:01:51

0:03:57

0:03:57

0:04:53

0:04:53

0:24:53

0:24:53

0:06:53

0:06:53

0:00:26

0:00:26

0:09:19

0:09:19

0:02:33

0:02:33

0:00:48

0:00:48

0:00:53

0:00:53

0:23:19

0:23:19

0:06:59

0:06:59

0:13:50

0:13:50

0:05:42

0:05:42

0:02:57

0:02:57

0:01:49

0:01:49

0:08:56

0:08:56

0:11:08

0:11:08

0:02:33

0:02:33