filmov

tv

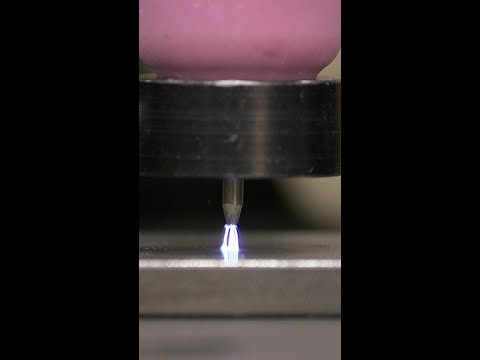

How to do TIG Welding Cast Aluminum, TIG ACDC 201 By CANAWELD PART 2

Показать описание

Cast Aluminum welding tutorial video from Canaweld!

Equipment used in this video: TIG AC/DC 201

The TIG AC/DC 201 Pulse is a portable, powerful and versatile welding machine. This unit is capable of either AC or DC TIG welding (stainless, mild steel and aluminum) or SMAW Stick welding. The professional pulse features of the machine combined with its HF start, make it ideal for welders looking to perform high-quality TIG welds with no distortion for even very thin steel alloys or aluminum.

CONNECT with CANAWELD:

Equipment used in this video: TIG AC/DC 201

The TIG AC/DC 201 Pulse is a portable, powerful and versatile welding machine. This unit is capable of either AC or DC TIG welding (stainless, mild steel and aluminum) or SMAW Stick welding. The professional pulse features of the machine combined with its HF start, make it ideal for welders looking to perform high-quality TIG welds with no distortion for even very thin steel alloys or aluminum.

CONNECT with CANAWELD:

Learning how to TIG weld made easy

How do I start to learn Tig Welding?

the FIRST thing you should learn tig welding

4 Tips To Make YOU a BETTER TIG Welder

TIG Welding Basics for Beginners

BEGINNER'S GUIDE How-To TIG Weld & Welding Basics

What is TIG Welding? (GTAW)

The FIRST 3 things to learn tig welding.

TIG Welding 101 - Walking the Cup

TIG Welding Aluminum

TIG Welding 101: An All Inclusive Introduction to GTAW

Beginner TIG welders NEED to know this...

TIG Welding Basics - SIMPLE Tips & Tricks How to Get Started

🔥 2 HUGE TIPS for tig welding mild steel 🔥

TFS: The Secret to Perfect Stainless TIG Welds

Stop doing this to yourself tig welding! Follow this tip! #shorts

Before Any Tig Welding Pass, do This for 5 Seconds

Handyman's Amazing TIG Welding Techniques That Work Extremely Well

Tig welding Walking The Cup techniques tips & hacks on a stainless steel plate #Shorts

How To Tig Weld Stainless in 3 Hours- COMPLETE LESSON

How to Tig Weld Aluminum in 3 hours- COMPLETE LESSON PLAN

4 Types of Welding Explained: MIG vs TIG vs Stick vs Flux Core

the 3 BEST SETTINGS to start tig welding

Your Very First TIG Welds with EXTREME Detail

Комментарии

0:21:10

0:21:10

0:11:52

0:11:52

0:03:20

0:03:20

0:07:26

0:07:26

0:31:44

0:31:44

0:33:13

0:33:13

0:03:59

0:03:59

0:10:23

0:10:23

0:13:24

0:13:24

0:05:14

0:05:14

0:38:44

0:38:44

0:00:18

0:00:18

0:39:41

0:39:41

0:09:07

0:09:07

0:21:24

0:21:24

0:00:59

0:00:59

0:08:59

0:08:59

0:08:26

0:08:26

0:00:58

0:00:58

0:24:55

0:24:55

0:20:27

0:20:27

0:11:27

0:11:27

0:12:11

0:12:11

0:43:36

0:43:36