filmov

tv

How to Weld a 2G Horizontal Plate Using the Fluxcore Process

Показать описание

In this video, Kase Ford, Welding Instructor at Tulsa Welding School shows you how to weld a 2G horizontal plate using the fluxcore process.

Tulsa Welding School was founded in 1949 by two welders who recognized a strong demand for skilled tradesman in their industry. Over 60 years later, Tulsa Welding School (TWS) has evolved into an educational institution that prepares students for various skilled trade careers with a multitude of specialties and applications. Graduates from Tulsa Welding School are trained to have the knowledge, skills and essential attitude to immediately enter their chosen profession.

Connect with us:

Tulsa Welding School was founded in 1949 by two welders who recognized a strong demand for skilled tradesman in their industry. Over 60 years later, Tulsa Welding School (TWS) has evolved into an educational institution that prepares students for various skilled trade careers with a multitude of specialties and applications. Graduates from Tulsa Welding School are trained to have the knowledge, skills and essential attitude to immediately enter their chosen profession.

Connect with us:

2G Root welding method cap 7018

6010 Root Tips - 2g Plate at GA Trade School

How to WELD a 2G V-Groove 6010 Root 7018 Fill and Cap (LIKE A BOSS)

Learn how to weld 2G horizontal | welding tips

How to Weld a 2G Open Root 6010 and 7018

How to Weld a 2G Horizontal Plate Using the Fluxcore Process

Stick Welding Tips- 7018 2g Plate Test

2G Root welding method cap 7018

Guidelines for practicing 2G welding that beginners should practice

7018 2G Practice Plate - for Welding Students

How to master HORIZONTAL stick welding? | 2G Back Grind

Welding Certification Position 2G: Horizontal Groove Weld

How to Weld a 2G Horizontal MIG Combo Plate with Flux Core

Combo Pipe Welding | 2G TIG Root, 7018 Fill Cap

How to Weld a 2G 2-Inch TIG All the Way ~ Tulsa Welding School

not many home welders know how to weld a small corner 2G joint

How To Weld: 2G 4' SCH 80 Open Butt V Groove!!

How to Weld 2G with a Half-Inch Plate With a Backing Strip ~ Tulsa Welding School

Types of Welding Positions ( 1G, 2G, 3G, 4G, 5G, 6G & 1F, 2F , 3F, 4F )

HOW TO weld GMAW 2G/Jak spawać Mag 135 BW PC

SMAW 7018 Horizontal 2F Tee | Welding Tips & Tricks #Welding #Tutorial #ArcWelding

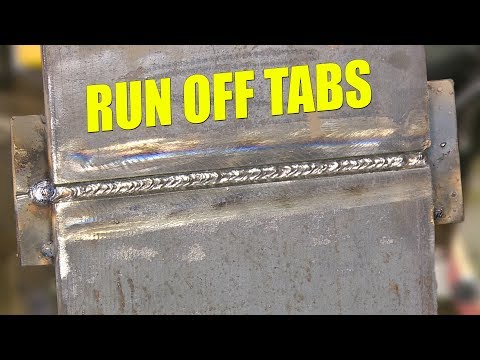

🔥 2G SMAW with Run Off Tabs

What is 2G, 6G, and 5G weld #shorts

Horizontal welding 2G weld stick test

Комментарии

0:10:27

0:10:27

0:06:39

0:06:39

0:08:18

0:08:18

0:06:31

0:06:31

0:30:01

0:30:01

0:11:20

0:11:20

0:10:55

0:10:55

0:05:07

0:05:07

0:04:18

0:04:18

0:09:22

0:09:22

0:19:07

0:19:07

0:03:34

0:03:34

0:14:23

0:14:23

0:18:58

0:18:58

0:32:28

0:32:28

0:12:40

0:12:40

0:14:42

0:14:42

0:31:51

0:31:51

0:04:59

0:04:59

0:07:11

0:07:11

0:05:31

0:05:31

0:09:27

0:09:27

0:00:26

0:00:26

0:08:11

0:08:11