filmov

tv

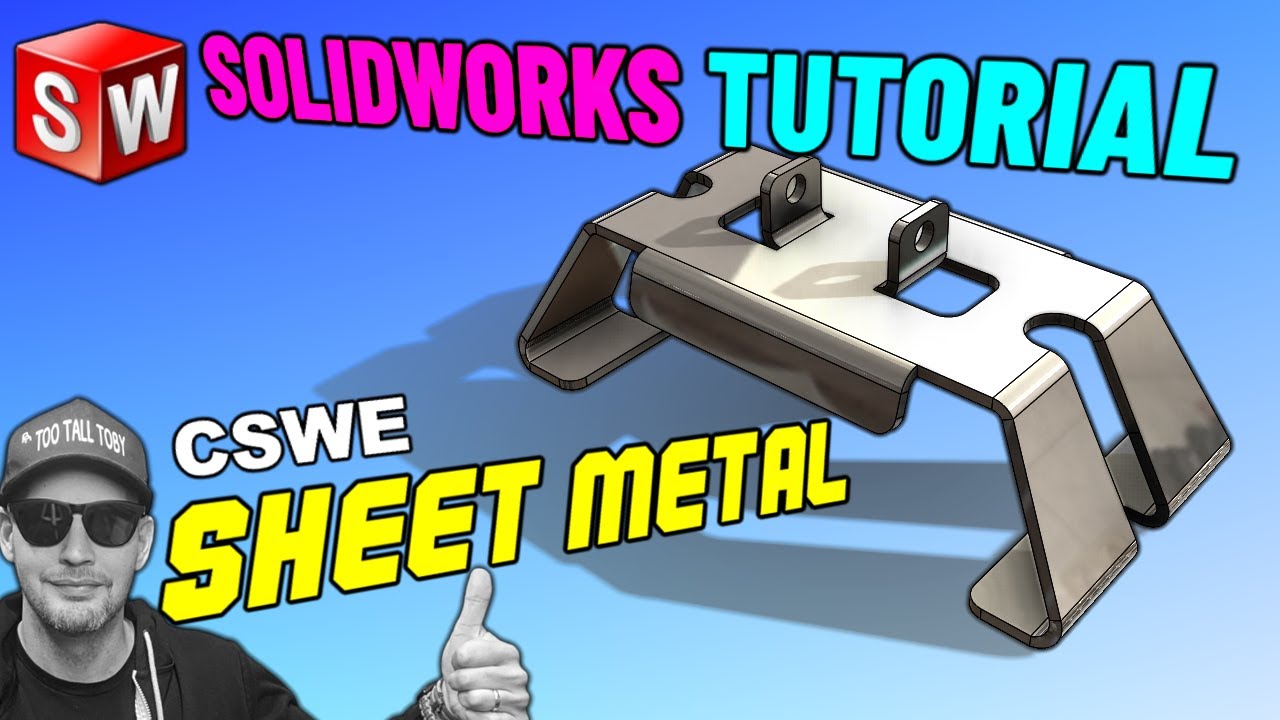

SolidWorks Sheet Metal Tutorial - METAL CLIP - 23-02-02

Показать описание

0:00 - INTRO

2:08 - GAME PLAN - Some TRICKY areas

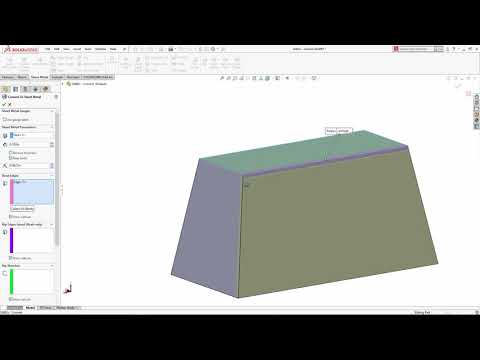

4:05 - First Sketch and Base Flange

5:00 - TECHNIQUE 1 - Discussion of a technique that didn't work very well...

7:54 - TECHNIQUE 2 - REVERTING BACK to original base flange

8:35 - Change original sketch to have a sharp bottom

9:00 - Create flared out section of angled flange using BASE FLANGE/TAB

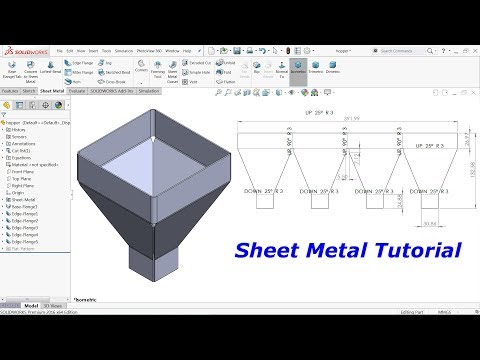

9:55 - Create EDGE FLANGE on the bottom of the part using parallel to face

10:40 - Discussion of FLANGE POSITION

12:11 - Flange Length - up to vertex? CAN'T USE SKETCH POINT!!

13:35 - Double Tombstone Cut Extrude

14:20 - Discussion of NORMAL CUT option in sheet metal

17:32 - Upper Rectangular Cut - AVOID EQUALS relationship on a rectangle

19:28 - Upper Edge Flanges - Edit Flange Profile Sketch

20:38 - Cut Extrude HOLE in upper flange

21:07 - Final Flange - Flared out on sides

21:33 - COOL TRICK to calculate oddball dimensions

23:11 - Side Flange FILLETS and MIRROR

23:28 - Bottom Flange Fillets

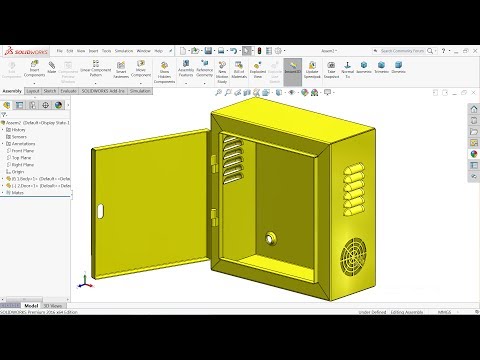

23:40 - MIRROR ALL

24:00 - EVALUATE MASS PROPERTIES and checking my answer

24:48 - Conclusion

In this #solidworks tutorial for #beginners , SolidWorks Expert TooTallToby will show #howto use the #,Bassflange tab command and #edgeflange command as well as explain how to get started creating a 3D model from a 2D print

Love dogecoin? So do we!! TTT DOGE wallet address: DKfGVFe1SbeZCff3i3zPS34Wq8PafVs1Zf

Комментарии

0:11:35

0:11:35

0:12:52

0:12:52

0:12:39

0:12:39

0:08:20

0:08:20

0:13:42

0:13:42

0:36:03

0:36:03

0:18:09

0:18:09

0:13:10

0:13:10

0:03:37

0:03:37

0:24:11

0:24:11

0:12:14

0:12:14

0:14:40

0:14:40

0:27:03

0:27:03

0:31:42

0:31:42

0:14:39

0:14:39

0:19:42

0:19:42

0:13:26

0:13:26

0:07:02

0:07:02

0:12:08

0:12:08

0:17:41

0:17:41

0:28:00

0:28:00

0:25:45

0:25:45

0:15:18

0:15:18

0:28:18

0:28:18