filmov

tv

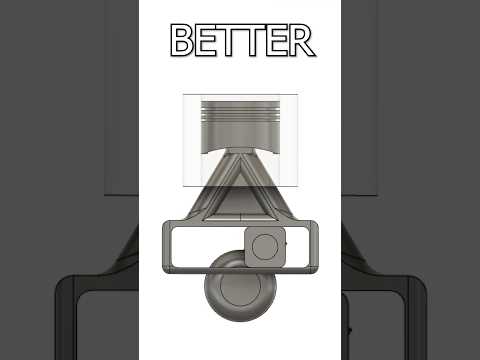

6 Cylinder Engine with Only 5 Moving Parts

Показать описание

Here's an "Elbow Engine" that I made very loosely based on the plan

in the July 1965 issue of Popular Mechanics and on Julius de Waal's plan that I found on a model engineering website.

It is very simple but has to be machined very precisely.

It's made out of brass, stainless steel, aluminium and delrin.

in the July 1965 issue of Popular Mechanics and on Julius de Waal's plan that I found on a model engineering website.

It is very simple but has to be machined very precisely.

It's made out of brass, stainless steel, aluminium and delrin.

The Only 9 Best Sounding 6-Cylinder Bikes Ever Made

1956 Chevrolet 6 Cylinder (MOTOR ONLY)- SOLD!

Which Engine sounds the Best? #shorts #v6 #v8 #v10 #v12 #w16 #engine

Honda CBX 6 Cylinder superbike ‼️|Exhaust sound🔊

Best Sounding 6-Cylinder Powered Cars

[Pure Sound Only] 1966 Honda RC166 Start | 6 Cylinder 250cc Beast

6 Cylinder Engine with Only 5 Moving Parts

Why All Semi-Trucks Use Inline-six Engines?

2007 Porsche 911 Turbo !

Just a inline 6 cylinder. #1968 #c10 #stepside

These are the STRANGEST 6-cylinder engines | Ep. 1

Testing Engine

Six cylinder firing order || 6 cylinder in-line engine 🤩🤔 How to work?

Is This Toughest US 6-Cylinder?

The Strongest Inline-Six Engine Is...

Honda CBX1000 F1 Sound! Six Cylinder Madness 🤩🚀😮

ISUZU 6 Cylinder Engine Filled With Water? Motor Sunk? Mechanical Genius Revived It!

What's the name of the second engine? #engineering #engine #hp #power #d4a #thumper #jdm #toyot...

These Six-Cylinder Engines Were LITERALLY Hard to Kill..

GM Atlas 4 vs 5 vs 6 Cylinder Engine Comparison

The TOP 3 4 Cylinder Engines of All Time 😳 #shorts

Engine cylinder piston cleaning easily 😃😅 #shorts

Diesel Engine vs Petrol Engine: INTERNAL COMBUSTION ENGINE📌 #engine #automobile #automotive#engines...

10 Most Reliable 6-Cylinders Which Run Forever

Комментарии

0:21:18

0:21:18

0:02:08

0:02:08

0:00:30

0:00:30

0:00:13

0:00:13

0:00:38

0:00:38

![[Pure Sound Only]](https://i.ytimg.com/vi/RcGGYMRt9Kg/hqdefault.jpg) 0:01:58

0:01:58

0:04:55

0:04:55

0:06:31

0:06:31

0:01:47

0:01:47

0:00:21

0:00:21

0:09:49

0:09:49

0:00:18

0:00:18

0:00:16

0:00:16

0:10:14

0:10:14

0:00:14

0:00:14

0:00:27

0:00:27

1:49:06

1:49:06

0:00:10

0:00:10

0:17:25

0:17:25

0:17:42

0:17:42

0:00:17

0:00:17

0:00:17

0:00:17

0:00:11

0:00:11

0:09:27

0:09:27