filmov

tv

The Correct Height of a Toilet Flange

Показать описание

Ergonomics | Monitors: Height

How To Choose The Best Screen Height To Avoid Neck Pain

Why Tall People Die Younger: The ideal height for the longest life

Height Measurement

How to Set Your Bicycle Seat Height

Neuroscientist : Your HEIGHT is determined by this | Andrew Huberman | Dr. Kyle Gillett

Correct Paddle Height / How To Find The Right Height For Your SUP Paddle

The Correct Height of a Toilet Flange

The best height adjustable desk

The Perfect Bench Height | what height should your Woodworking Bench

How to Measure your Height Correctly

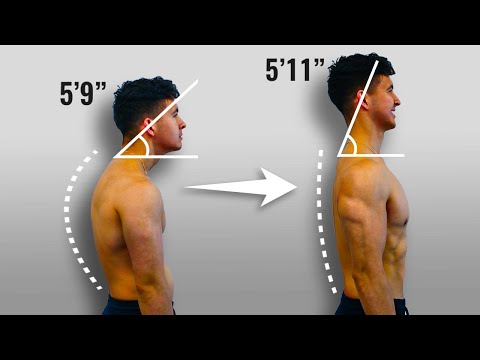

The PERFECT 5 Minute Posture Routine To Increase Your Height

Setting the Right Height - Piano Sitting Posture

How to Accurately Measure Your Height At Home

How to Measure a Cane for Correct Height for a User

How to measure the ideal height for your tv on the wall | TV Wall Mounts | Vogel's

Easy Way to Measure the Correct Height for Your Walking Cane

How to decide the correct height of Kitchen Countertop? | Kitchen Planning Tips

How To Find The Perfect Saddle Height On Your Bike

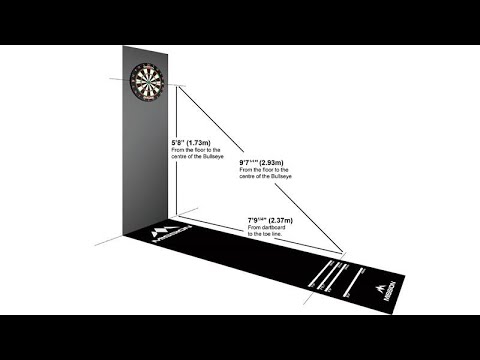

How To Setup A Dartboard At The Correct Height?

Seeing if boys lie about their height 😂 #shorts #comedy #interviews #socialexperiment #funny

How to measure dartboard height and Oche (throwline) distance.

COMPARISON: Normal Height for Every Age ( Male ) #shorts #height

+15 cm more height with limb lengthening surgery #limblengthening #gettaller #longlegs #shorts

Комментарии

0:01:24

0:01:24

0:05:46

0:05:46

0:13:26

0:13:26

0:00:52

0:00:52

0:04:02

0:04:02

0:00:44

0:00:44

0:06:51

0:06:51

0:04:11

0:04:11

0:00:15

0:00:15

0:11:34

0:11:34

0:01:00

0:01:00

0:09:20

0:09:20

0:08:46

0:08:46

0:02:15

0:02:15

0:01:31

0:01:31

0:00:26

0:00:26

0:02:33

0:02:33

0:01:17

0:01:17

0:06:52

0:06:52

0:01:51

0:01:51

0:00:42

0:00:42

0:01:19

0:01:19

0:00:44

0:00:44

0:00:56

0:00:56