filmov

tv

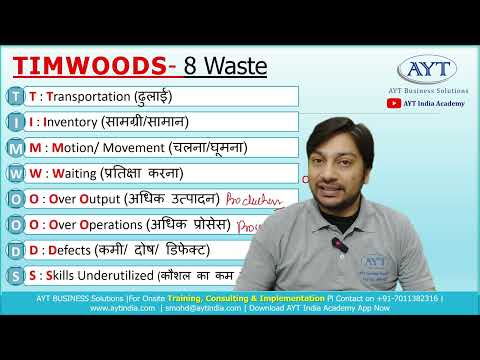

𝟴 𝗪𝗮𝘀𝘁𝗲𝘀 𝗼𝗳 𝗟𝗲𝗮𝗻 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 [ Lean manufacturing wastes ] Lean manufacturing waste elimination

Показать описание

This video explains the 8 different types of waste in Lean Manufacturing. Traditional lean identifies eight key areas of waste – typically referred to as the Eight Deadly Wastes and the acronym for the eight wastes is DOWNTIME.

📹 𝐁𝐞𝐬𝐭 𝐋𝐞𝐚𝐧 𝐒𝐢𝐱 𝐬𝐢𝐠𝐦𝐚 & 𝐐𝐮𝐚𝐥𝐢𝐭𝐲 𝐓𝐨𝐨𝐥𝐬 𝐕𝐢𝐝𝐞𝐨𝐬

--------------------------------------------------------------------------------

⏱️ 𝑻𝒊𝒎𝒆 𝑺𝒕𝒂𝒎𝒑 ⏱️

--------------------------------

0:00 - Introduction

0:34 - 8 deadly wastes of Lean

2:27 - Acronym "DOWNTIME" for 8 deadly wastes

3:22 - Waste 1 ( #Transportation)

5:12 - Waste 2 (#Inventory )

6:58 - Waste 3 (#Motion)

8:10 - Waste 4 (#Waiting)

10:00 - Waste 5 (#OverProduction)

11:48 - Waste 6 (#OverProcessing)

13:35 - Waste 7 (#Defect)

15:17 - Waste 8 (#UnutilizedSkills)

📢📢 📢📢 𝐅𝐨𝐥𝐥𝐨𝐰𝐬 𝐮𝐬 𝐨𝐧 𝑺𝒐𝒄𝒊𝒂𝒍 𝑴𝒆𝒅𝒊𝒂

-------------------------------------------------------------------------

✍️ 𝓓𝓲𝓼𝓬𝓵𝓪𝓲𝓶𝓮𝓻:

Copyright Disclaimer under section 107 of the Copyright Act of 1976, allowance is made for “fair use” for purposes such as criticism, comment, news reporting, teaching, scholarship, education and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. The information contained in this video is just for educational and informational purposes only and does not have any intention to mislead or violate Google and YouTube community guidelines or policy. I respect and follow all terms & conditions of Google & YouTube.

𝐂𝐨𝐦𝐦𝐨𝐧 𝐊𝐞𝐲 𝐬𝐞𝐚𝐫𝐜𝐡 𝐫𝐞𝐥𝐚𝐭𝐞𝐝 𝐭𝐨 𝐭𝐡𝐢𝐬 𝐭𝐨𝐩𝐢𝐜 :

----------------------------------------------------------------------

#Lean #LeanSixSigma #Digital_e_Learning #Project_Management #Lean #LeanSixSigma #SixSigma #Quality

Lean Manufacturing wastes

lean manufacturing 8 wastes

lean manufacturing 7 wastes

What are the 7 wastes in lean manufacturing?

What are the 8 deadly wastes?

What are the 8 Wastes of Lean?

What are the 7 wastes in Six Sigma?

how to reduce waste in lean manufacturing

7 deadly wastes lean manufacturing

📹 𝐁𝐞𝐬𝐭 𝐋𝐞𝐚𝐧 𝐒𝐢𝐱 𝐬𝐢𝐠𝐦𝐚 & 𝐐𝐮𝐚𝐥𝐢𝐭𝐲 𝐓𝐨𝐨𝐥𝐬 𝐕𝐢𝐝𝐞𝐨𝐬

--------------------------------------------------------------------------------

⏱️ 𝑻𝒊𝒎𝒆 𝑺𝒕𝒂𝒎𝒑 ⏱️

--------------------------------

0:00 - Introduction

0:34 - 8 deadly wastes of Lean

2:27 - Acronym "DOWNTIME" for 8 deadly wastes

3:22 - Waste 1 ( #Transportation)

5:12 - Waste 2 (#Inventory )

6:58 - Waste 3 (#Motion)

8:10 - Waste 4 (#Waiting)

10:00 - Waste 5 (#OverProduction)

11:48 - Waste 6 (#OverProcessing)

13:35 - Waste 7 (#Defect)

15:17 - Waste 8 (#UnutilizedSkills)

📢📢 📢📢 𝐅𝐨𝐥𝐥𝐨𝐰𝐬 𝐮𝐬 𝐨𝐧 𝑺𝒐𝒄𝒊𝒂𝒍 𝑴𝒆𝒅𝒊𝒂

-------------------------------------------------------------------------

✍️ 𝓓𝓲𝓼𝓬𝓵𝓪𝓲𝓶𝓮𝓻:

Copyright Disclaimer under section 107 of the Copyright Act of 1976, allowance is made for “fair use” for purposes such as criticism, comment, news reporting, teaching, scholarship, education and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. The information contained in this video is just for educational and informational purposes only and does not have any intention to mislead or violate Google and YouTube community guidelines or policy. I respect and follow all terms & conditions of Google & YouTube.

𝐂𝐨𝐦𝐦𝐨𝐧 𝐊𝐞𝐲 𝐬𝐞𝐚𝐫𝐜𝐡 𝐫𝐞𝐥𝐚𝐭𝐞𝐝 𝐭𝐨 𝐭𝐡𝐢𝐬 𝐭𝐨𝐩𝐢𝐜 :

----------------------------------------------------------------------

#Lean #LeanSixSigma #Digital_e_Learning #Project_Management #Lean #LeanSixSigma #SixSigma #Quality

Lean Manufacturing wastes

lean manufacturing 8 wastes

lean manufacturing 7 wastes

What are the 7 wastes in lean manufacturing?

What are the 8 deadly wastes?

What are the 8 Wastes of Lean?

What are the 7 wastes in Six Sigma?

how to reduce waste in lean manufacturing

7 deadly wastes lean manufacturing

Комментарии

0:17:06

0:17:06

0:07:49

0:07:49

0:05:34

0:05:34

0:01:55

0:01:55

0:03:07

0:03:07

0:04:13

0:04:13

0:20:31

0:20:31

0:05:42

0:05:42

0:01:35

0:01:35

0:13:08

0:13:08

0:14:06

0:14:06

0:01:53

0:01:53

0:03:29

0:03:29

0:03:04

0:03:04

0:05:00

0:05:00

0:01:22

0:01:22

0:05:01

0:05:01

0:04:56

0:04:56

0:04:12

0:04:12

0:23:05

0:23:05

0:01:35

0:01:35

0:02:01

0:02:01

0:01:33

0:01:33

0:10:54

0:10:54