filmov

tv

Steel Numbering System

Показать описание

In this video I give a brief explanation of the AISI steel numbering system for carbon, alloy, and tool steels. Also, I discuss some of the steels we use in our production as well as offer for sale.

CORRECTION: The carbon content is actually expressed in hundredths of percent rather than tenths as I said in the video.

CORRECTION: The carbon content is actually expressed in hundredths of percent rather than tenths as I said in the video.

Steel Numbering System

SAE STEEL GRADES: Major Classifications of Carbon and Alloy Steel

Grade Guide: AISI A36 Steel | Metal Supermarkets

Advance Steel - Numbering with Drawing Number Method

The Four Types of Steel (Part 1) | Metal Supermarkets

Getting Started with Advance Steel: Part 30 - Run the numbering again

Steel Types - Stainless Steel Vs Carbon Steel Explained.

AISI/SAE Steel Designation System

How to calculate the weight of a steel bar | #construction #steelbars #civilEngg #civilengeenring

What Is the Difference Between 304 and 316 Stainless Steel? | Technical Tuesday

SS Pipe Manufacturer 304 Stainless Steel Pipes Tube Price

Stainless steel grade testing liquid | Stainless steel quality testing ||

Star Brite Chrome and Stainless Steel Polish Chemical

Orcher Stainless Steel Modular Kitchen - 1

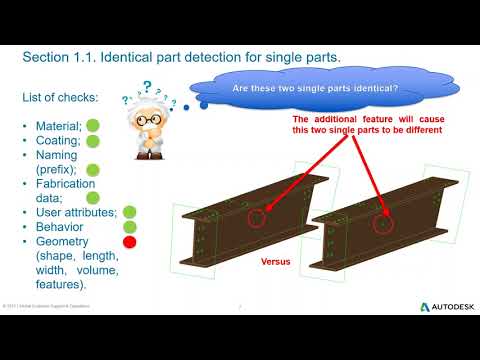

14. Numbering (Identical part detection) in Advance Steel 2018

Polishing stainless steel to a high-gloss finish with an angle polisher – tips for discs and speed

⭐ Product Link in Comments ⭐Elegant Stainless Steel Waterfall Kitchen Sink #viral

Stainless Steel Lunchbox System

Steel Types: Carbon-Steel Explained in 3 Minutes

Applying The Nashville Number System To Common Song Structures | Pedal Steel Guitar

Advance Steel Numbering with Standard Parts

Mingyou 17SEA Mini Steel Security Safe Box Electronic Home Safety Locker Small Caja Fuerte

30 - Run numbering after modifications with Autodesk Advance Steel

Process of Manufacturing Stainless Steel Quality Restaurant Spoon

Комментарии

0:07:47

0:07:47

0:03:25

0:03:25

0:02:38

0:02:38

0:03:03

0:03:03

0:03:41

0:03:41

0:00:35

0:00:35

0:08:48

0:08:48

0:14:55

0:14:55

0:01:01

0:01:01

0:01:51

0:01:51

0:00:25

0:00:25

0:01:24

0:01:24

0:00:28

0:00:28

0:01:31

0:01:31

0:49:15

0:49:15

0:01:52

0:01:52

0:00:34

0:00:34

0:00:18

0:00:18

0:02:40

0:02:40

0:14:52

0:14:52

0:05:48

0:05:48

0:00:48

0:00:48

0:00:25

0:00:25

0:06:07

0:06:07