filmov

tv

Restoring old leaf springs DIY

Показать описание

Follow along as I disassemble and clean up my old leaf springs and give them a fresh coat of paint. Then reassemble them to finish the shackle flip lift kit.

Thanks for watching and if you like the video please hit the thumbs up and subscribe if you want to see more videos like it.

Consider buying me a coffee to help support this channel.

Amazon affiliate links:

Ospho rust treatment

Follow me on instagram

Follow me on facebook @offroadfarm

Email me at:

As an Amazon Associate I earn from qualifying purchases.

Thanks for watching and if you like the video please hit the thumbs up and subscribe if you want to see more videos like it.

Consider buying me a coffee to help support this channel.

Amazon affiliate links:

Ospho rust treatment

Follow me on instagram

Follow me on facebook @offroadfarm

Email me at:

As an Amazon Associate I earn from qualifying purchases.

Restoring old leaf springs DIY

Restoring old leaf springs DIY

REARCH LEAF SPRINGS AT HOME FOR FREE - Easy Leaf Spring Re-Arching | DIY Lift Kit | Leaf Spring Sag

Restoring old leaf springs DIY #leafspring #diy #mechanic #trucks #mechaniclife #automotive

Amazing Technique Of Repairing A Leaf Spring | Van Suspension System

Restoring Leaf Springs of a Truck | Old Leaf Spring Replacing

Land Rover Restoration Part 12 - Refurbishing Leaf Springs

Restoring old leaf springs DIY#shorts #mechanic #mechanicaltips #mechanical #viralstatus #automobile

Rifleman’s Knife Build

Land Rover Series 2 Restoration: How to Rebuild a Leaf Spring

Restoring The Rusty Old Leaf Springs on Our Vintage 70s Bedford Truck: Full Restoration & Rebuil...

Amazing Restoration Of An Old Leaf Spring Suspension - Indigenous Repairing & Restoration

Removing Leaf Springs - One Minute Monday by EATON Detroit Spring

Mini Bus Leaf Spring Restoration | Fixing Broken Old leaf Spring Suspension System

Fixing An Old Leaf Spring

Leaf spring reset: Can you fix a sagging spring? | Auto Expert John Cadogan

Restoration of rusty and old truck Leaf Spring

Leaf Spring Re-Arching

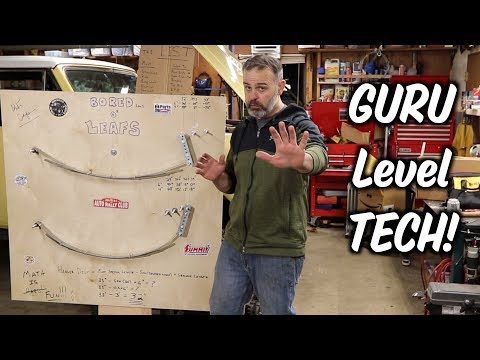

5.04 Leaf Springs & Shackles GURU Level Tech!

Restoration leaf spring| leaf spring manufacturing| leaf spring replacement| Leaf spring

How to Replace Leaf Springs and Lift your Truck

Dirt Cheap, Simple Upgrade For All Leaf Spring Cars And Trucks

6x4 Trailer Repairs - New Leaf Springs / Mounting Points / Rust Repairs and Greased Bearings.

Truck Sagging, Banging, or Rattling in the Rear? New Leaf Springs Can Smooth Out These Problems!

Комментарии

0:09:56

0:09:56

0:17:47

0:17:47

0:11:44

0:11:44

0:00:14

0:00:14

0:08:37

0:08:37

0:01:41

0:01:41

0:16:06

0:16:06

0:00:15

0:00:15

0:37:52

0:37:52

0:11:02

0:11:02

0:26:52

0:26:52

0:07:20

0:07:20

0:00:40

0:00:40

0:08:04

0:08:04

0:00:59

0:00:59

0:12:21

0:12:21

0:00:59

0:00:59

0:04:50

0:04:50

0:19:44

0:19:44

0:00:58

0:00:58

0:17:57

0:17:57

0:08:39

0:08:39

0:32:34

0:32:34

0:06:17

0:06:17