filmov

tv

How to Implement Standard Work

Показать описание

Implementing Standard Work involves: identify process, document current state, analyze for waste, develop clear instructions, train staff, implement, monitor performance, and continuously improve for consistency, efficiency, and quality.

📌 Related videos

▶ What is Standard Work

▶ Why Standard Work is Important

✍ Here is the transcript of the video:

Implementing Standard Work in an industrial setting involves several key steps:

1. Identify the Process:

Start by identifying the process that needs standardization. This could be a task that is performed frequently, has high variability, or is critical for quality or safety.

2. Document Current Process:

Observe the process in its current state and document each step.

This includes the sequence of activities, the time taken for each activity, the tools and materials used, and the layout of the work station.

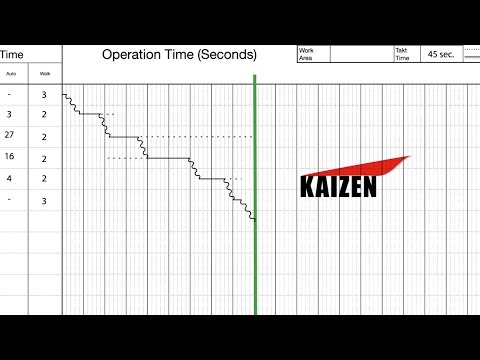

3. Analyze and Improve:

Analyze the current process to identify waste and opportunities for improvement.

This could involve eliminating unnecessary steps, reducing movement, improving the layout of the work station, or standardizing the use of tools and materials.

The goal is to create a process that is efficient, effective, and safe.

4. Develop Standard Work Instructions:

Based on the improved process, develop Standard Work instructions. These should be clear, concise, and visually oriented, providing a step-by-step guide for performing the task.

They should also include safety and quality checks.

5. Train Employees:

Train all employees who perform the task on the Standard Work instructions. This should involve both classroom training and hands-on practice at the work station.

6. Implement and Monitor:

Implement the Standard Work and monitor its performance. This could involve tracking metrics like cycle time, quality, and safety incidents.

7. Review and Improve:

Regularly review the Standard Work and make improvements based on feedback from employees and performance data.

▶ Conclusions

Remember, Standard Work is not a one-time activity but a continuous cycle of improvement.

By following these steps, industrial engineers can implement Standard Work, driving consistency, efficiency, and quality in their operations.

ツ CONNECT WITH ME ツ

Hi,

my name is Mark Anderson a 20+ year Lean Expert.

I have created LeanVlog because I want to spread Lean Thinking worldwide and I think the video is the most effective way to teach, learn, and spread knowledge.

If you want to stay in touch with me you can choose the channel you prefer.

A) Linkedin

B) Latest Videos and Playlist

C) Telegram

#standardwork #leanmanufacturing

📌 Related videos

▶ What is Standard Work

▶ Why Standard Work is Important

✍ Here is the transcript of the video:

Implementing Standard Work in an industrial setting involves several key steps:

1. Identify the Process:

Start by identifying the process that needs standardization. This could be a task that is performed frequently, has high variability, or is critical for quality or safety.

2. Document Current Process:

Observe the process in its current state and document each step.

This includes the sequence of activities, the time taken for each activity, the tools and materials used, and the layout of the work station.

3. Analyze and Improve:

Analyze the current process to identify waste and opportunities for improvement.

This could involve eliminating unnecessary steps, reducing movement, improving the layout of the work station, or standardizing the use of tools and materials.

The goal is to create a process that is efficient, effective, and safe.

4. Develop Standard Work Instructions:

Based on the improved process, develop Standard Work instructions. These should be clear, concise, and visually oriented, providing a step-by-step guide for performing the task.

They should also include safety and quality checks.

5. Train Employees:

Train all employees who perform the task on the Standard Work instructions. This should involve both classroom training and hands-on practice at the work station.

6. Implement and Monitor:

Implement the Standard Work and monitor its performance. This could involve tracking metrics like cycle time, quality, and safety incidents.

7. Review and Improve:

Regularly review the Standard Work and make improvements based on feedback from employees and performance data.

▶ Conclusions

Remember, Standard Work is not a one-time activity but a continuous cycle of improvement.

By following these steps, industrial engineers can implement Standard Work, driving consistency, efficiency, and quality in their operations.

ツ CONNECT WITH ME ツ

Hi,

my name is Mark Anderson a 20+ year Lean Expert.

I have created LeanVlog because I want to spread Lean Thinking worldwide and I think the video is the most effective way to teach, learn, and spread knowledge.

If you want to stay in touch with me you can choose the channel you prefer.

A) Linkedin

B) Latest Videos and Playlist

C) Telegram

#standardwork #leanmanufacturing

0:02:11

0:02:11

0:02:34

0:02:34

0:02:35

0:02:35

0:01:35

0:01:35

0:02:33

0:02:33

0:13:03

0:13:03

0:09:48

0:09:48

0:04:52

0:04:52

0:10:49

0:10:49

0:03:07

0:03:07

0:10:18

0:10:18

0:08:13

0:08:13

0:00:50

0:00:50

0:01:57

0:01:57

0:11:29

0:11:29

0:10:23

0:10:23

0:27:16

0:27:16

0:01:21

0:01:21

0:00:43

0:00:43

0:00:50

0:00:50

0:07:31

0:07:31

0:02:18

0:02:18

0:00:29

0:00:29

0:01:35

0:01:35