filmov

tv

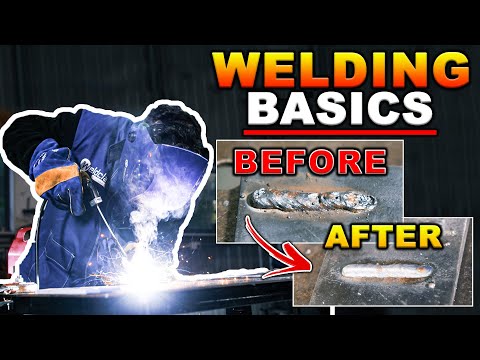

Learn to (Mig Weld) in A DAY pt. 3 (MIG Welding Thin Square Tubing)

Показать описание

This is pt. 3 of the video series "Learn to Mig Weld in a DAY". This video goes into depth on how to mig weld thin wall square tubing. For me this is one of the more difficult types of welding for the beginner. The problem lies with different style weld joints. You have inside corner joints, outside corner joints and also butt weld joints, and if that's not enough you are welding on thin wall tubing in very short runs. I even struggled on some of the joints and I also need more practice. I like to share my failures as well as my wins in these videos, so you can see that it don't always go as smoothly as people show!!! Hopefully you can take away some valuable tricks in this video to help speed up your learning curve. This type of weld joint is a familiar to the beginner because this is a common and easy bought type of material used by beginners. Hope this helps guys . Make sure to drop a comment, Like share and Subscribe. God Bless Have a Blessed day, Adrian at AC Designs Garage!!!!!!

My PO BOX PO BOX 782 Troutman NC 28166

Mig Welder Im using in video Link and coupon code below.

COUPON CODE For ARCCAPTAIN: AC DESIGNS

ArcCaptain Coupon Code AC Designs

Tools Links BELOW

My PO BOX PO BOX 782 Troutman NC 28166

Mig Welder Im using in video Link and coupon code below.

COUPON CODE For ARCCAPTAIN: AC DESIGNS

ArcCaptain Coupon Code AC Designs

Tools Links BELOW

Комментарии

0:08:29

0:08:29

0:14:40

0:14:40

0:22:14

0:22:14

0:27:18

0:27:18

0:04:53

0:04:53

0:22:24

0:22:24

0:16:27

0:16:27

0:12:40

0:12:40

0:03:10

0:03:10

0:16:21

0:16:21

0:07:44

0:07:44

0:04:15

0:04:15

0:25:13

0:25:13

1:15:34

1:15:34

0:11:47

0:11:47

0:16:44

0:16:44

0:11:36

0:11:36

0:18:42

0:18:42

0:00:16

0:00:16

0:17:28

0:17:28

0:18:25

0:18:25

0:09:34

0:09:34

0:25:53

0:25:53

0:10:02

0:10:02