filmov

tv

100W Solar panel || DIY or Buy

Показать описание

In this episode of DIY or Buy I will show you how I created a 100W solar panel by myself. Along the way you will learn how to wire up solar cells and how they are usually wired up in a commercial solar panel. At the end we will then evaluate whether the DIY version is cheaper to produce.

Thanks to JLCPCB for sponsoring this video

Music:

2011 Lookalike by Bartlebeats

Killing Time, Kevin MacLeod

100W Solar panel || DIY or Buy

100 Watt Solar Panel Kit Beginner Set-Up | How to and Step by Step Solar Kit Instructions

How Much Energy Does a 100 Watt Solar Panel Produce?

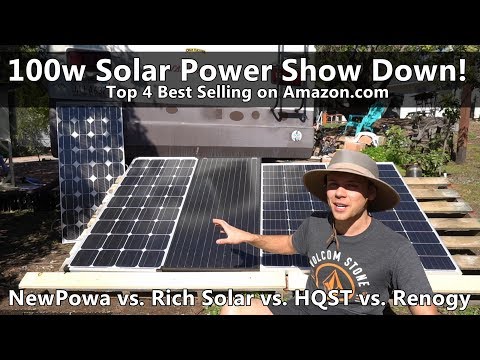

Top 4 Amazon.com 100w Solar Panels Tested! Renogy vs. HQST vs. Rich Solar vs. NewPowa

Best Wattage of Solar Panel for a DIY Camper Electrical System (and why there isn't a 'bes...

100w Renogy Solar Suitcase and Renogy Voyager Tested and Reviewed

Thunderbolt Solar 100 Watt Monocrystalline Solar Panels from Harbor Freight, a quick review!

DIY Lion Energy Solar System - Featuring the Lion 100W 12V Solar Panel

Unleashing EcoFlow Delta 2 Powerhouse with 2- 100W Solar Panel

Solar Panel + DIY Light Reflectors = More Power? Renogy vs Rich Solar vs Flexible Panel

CIGS Solar Panel Review - BougeRV CIGS Compact 100W #bougerv #solar #rvsolar #tinycamper

Renogy 100 Watt Solar panel VS Harbor Freight 100 Watt Solar panel

Solar Electric Air Heater! (100W 12V) - 100W Solar Panel runs it! - PV space heating!! Ez DIY

100w Budget DIY Campervan Flexible Solar Setup - How good is it?

DIY Portable Solar Panel Stand Mount Very Affordable

SolarSaga 100W Solar Panel Unboxing & how to parallel connect

Can You Power Your Entire House With This Ultra Cheap Solar System??

Eco-worthy 100w solar panel kit with leisure battery on garden shed - 1 year review

100W Solar Car Battery Maintainer

BEGINNER FRIENDLY Step-by-Step: DIY SOLAR GENERATOR for Emergency Power, RV, Shed... Ampere Time

100W Solar Light Floodlight

DIY 100W LED flashlight with solar panel

ROCKPALS RP100 100W Portable Solar Panel

Why are people NOT buying raw LiFePO4 cells?

Комментарии

0:09:06

0:09:06

0:11:15

0:11:15

0:04:06

0:04:06

0:10:31

0:10:31

0:04:18

0:04:18

0:06:46

0:06:46

0:02:33

0:02:33

0:01:37

0:01:37

0:06:38

0:06:38

0:11:47

0:11:47

0:08:02

0:08:02

0:08:24

0:08:24

0:05:21

0:05:21

0:09:04

0:09:04

0:17:33

0:17:33

0:00:39

0:00:39

0:21:37

0:21:37

0:03:33

0:03:33

0:04:09

0:04:09

0:22:34

0:22:34

0:00:16

0:00:16

0:15:05

0:15:05

0:00:39

0:00:39

0:08:31

0:08:31