filmov

tv

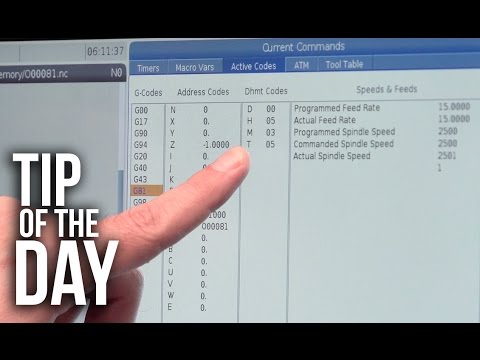

Programming Shortcuts on Your Haas Control – Save Keystrokes & Time! Haas Automation Tip of the Day

Показать описание

Spend less time programming at your Haas machine with these programming tips. Mark shows you how in this "TIP OF THE DAY."

In this video, Mark shows you how to reduce your keystrokes by 30% when programming by hand, using nothing more than some shortcuts and a setting that already exists in your Haas control.

If you enjoyed this video, please hit the like button and share it with a friend who'll find it helpful . . . and thanks!

Follow Haas:

In this video, Mark shows you how to reduce your keystrokes by 30% when programming by hand, using nothing more than some shortcuts and a setting that already exists in your Haas control.

If you enjoyed this video, please hit the like button and share it with a friend who'll find it helpful . . . and thanks!

Follow Haas:

Programming Shortcuts on Your Haas Control – Save Keystrokes & Time! Haas Automation Tip of the ...

How to Stop Your Program With an M-Code – Haas Automation Tip of the Day

Quick and Easy Backup of your Haas CNC Programs – Haas Automation Tip of the Day

Easily Convert Your MDI Program to Memory – Haas Automation Tip of the Day

View Your Haas Control From Your Computer or Phone - Haas Automation Tip of the Day

Apps Minute - Setting Up Remote Net Share on Your Haas Machine - Haas Automation, Inc.

TSC / TAB - Haas Keyboard Shortcut

Programming a M97 code - HAAS CNC Lathe example

Easily Create Your Own Custom M and G Codes – Haas Automation Tip of the Day

Get the info you need by customizing your Haas control home screen – Haas Automation Tip of the Day...

Copy Your CNC Programs Quickly and Easily – Haas Automation Tip of the Day

YOUR FEEDRATE IS WRONG! – Haas Automation Tip of the Day

Display the Axes You Want to See on Your Haas Control – Haas Automation Tip of the Day

Set Work Offsets in Seconds – Haas Automation Tip of the Day

Programming Made Easy With HAAS!

Haas' Visual Programming System for Lathes. How It Works. Haas Automation, Inc.

What's That Button Do - The 2ND HOME button on the Haas Control - Haas Tip of the Day

How to Take a Screenshot on Your Haas Control – Haas Automation Tip of the Day

Haas Apps Minute - Correctly Formatting G04

Apps Minute - Connect Your Haas Machine to the Internet

pick program haas

Haas VF-8 VMC, 1998- Chip Auger, Under Power

What is G-Code? – Haas Automation Tip of the Day

Use G53, not G28, to Cut Cycle Times and Position Your Lathe Turret – Haas Automation Tip of the Day...

Комментарии

0:02:34

0:02:34

0:05:42

0:05:42

0:03:49

0:03:49

0:02:13

0:02:13

0:03:13

0:03:13

0:02:10

0:02:10

0:00:52

0:00:52

0:11:29

0:11:29

0:04:40

0:04:40

0:03:54

0:03:54

0:01:07

0:01:07

0:06:50

0:06:50

0:02:30

0:02:30

0:11:30

0:11:30

0:03:37

0:03:37

0:05:06

0:05:06

0:02:13

0:02:13

0:03:40

0:03:40

0:01:22

0:01:22

0:01:24

0:01:24

0:01:07

0:01:07

0:00:37

0:00:37

0:06:17

0:06:17

0:08:24

0:08:24