filmov

tv

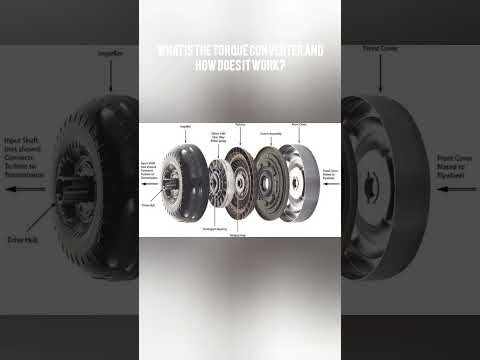

Exploding Torque Converter Fixed

Показать описание

Today I take care of my torque converter problem, turns out Comet clones don't really like being spun over 8000rpm. The Tork-Zilla has ZERO problems with the revs.

I solved my leaky carb problem by adjusting the float height and created a new leak with a fuel pressure regulator.

I solved my leaky carb problem by adjusting the float height and created a new leak with a fuel pressure regulator.

Комментарии