filmov

tv

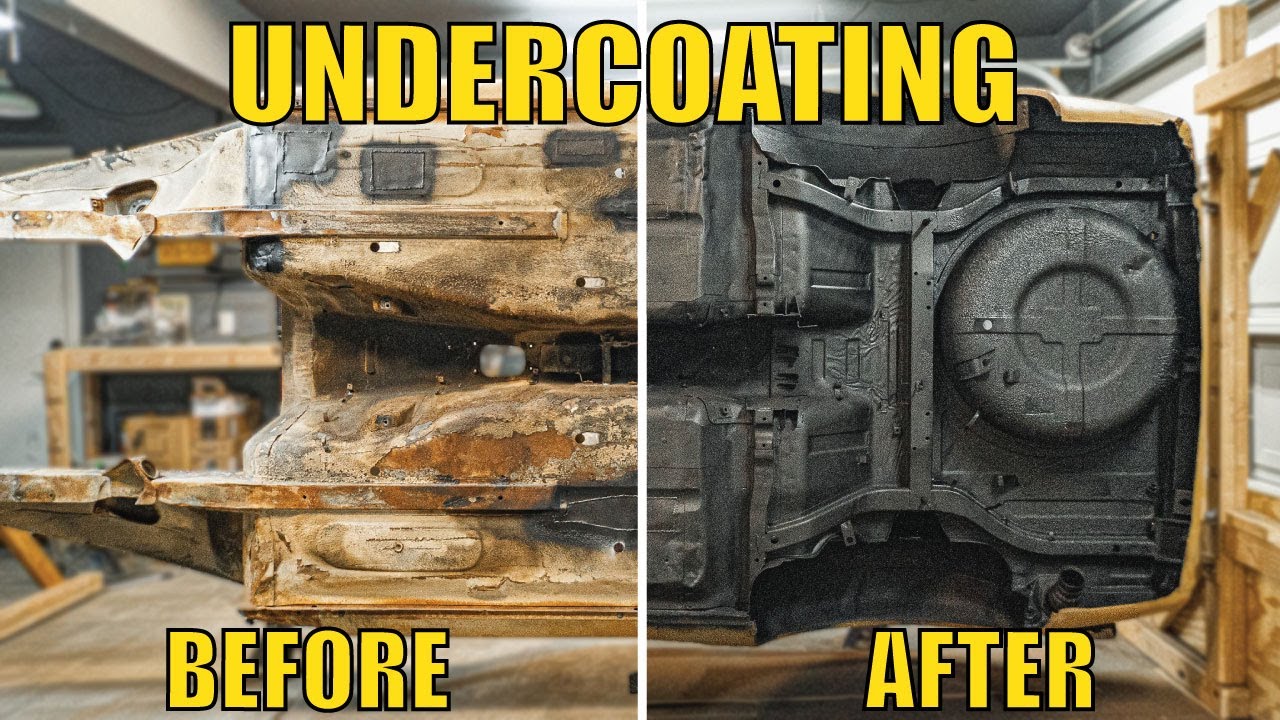

UNDERCOATING a Car For LESS Than $100 - Datsun 240z Restoration Part 13

Показать описание

In this episode, we are undercoating the Datsun! I'll take you through my process of undercoating a car for as cheap as possible without sacrificing results.

PART 13 of my Datsun Restoration Series

Links to almost everything used in this video -

^^Using these links to purchase makes me money from each sale and YOU PAY THE SAME AMOUNT! :)

Watch the other parts of this series:

BradBuilds

Subscribe for more videos!

Thanks!

_______________

Music

Numbered Sounds - Smile

Numbered Sounds - Aspirations

Numbered Sounds - Jet

PART 13 of my Datsun Restoration Series

Links to almost everything used in this video -

^^Using these links to purchase makes me money from each sale and YOU PAY THE SAME AMOUNT! :)

Watch the other parts of this series:

BradBuilds

Subscribe for more videos!

Thanks!

_______________

Music

Numbered Sounds - Smile

Numbered Sounds - Aspirations

Numbered Sounds - Jet

UNDERCOATING a Car For LESS Than $100 - Datsun 240z Restoration Part 13

How to PROPERLY Undercoat A Rusted Car or Truck. (Fluid Film Surface Shield, Woolwax)

How To Undercoat Your Car/Truck/SUV For Under $65 FAST!

Best Car Undercoating? Let's find out! Is Flex Seal the Best Rust & Salt Protection?

This is Why You NEVER Want to Use Rubberized Undercoatings!

BEFORE YOU UNDERCOAT YOUR TOYOTA TACOMA, WATCH THIS!

I Finally Found The Best Undercoating On The Market... Blaster Surface Shield

If You Do This, You'll Never Have to Repair Rust on Your Car

How to Undercoat Your Car: Impala SS

How to Undercoat a Jeep Wrangler Frame or Truck ***SMOOTH FINISH***

How To Undercoat Your Car using Old Engine Oil, CHEAP AND EASY!

Stop Rust Permanently! - Jay Leno's Garage

All you need to know about rust proofing your car

Real World Undercoating Test: Fluid Film, NH Oil, Krown and More...

FLUID FILM® Undercoating Tutorial

Stop Putting Undercoating on Your Car

The Secret to Turn a Normal Car into a Luxury Car - Sound Proofing

3M Car Care - Under body protection | Advaith Hyundai

Testing undercoating car with Fluidfilm sprayed from a cheap electric paint sprayer

Undercoating Your Vehicle with Woolwax: Is it Really Better than Fluid Film Though?

How to Remove and Paint Undercarriage Rust Using Krud Kutter

Ultra cheap Fluid Film spray kit - how to spray Fluid Film

How to PROPERLY Paint Over Rust. PART 1 of 2- Prep Work (Car Rust Repair)

Why It’s The Absolute Best Undercoating For Your Truck

Комментарии

0:17:08

0:17:08

0:27:55

0:27:55

0:09:41

0:09:41

0:15:14

0:15:14

0:07:14

0:07:14

0:07:38

0:07:38

0:13:08

0:13:08

0:06:29

0:06:29

0:16:43

0:16:43

0:11:27

0:11:27

0:01:56

0:01:56

0:04:14

0:04:14

0:02:38

0:02:38

0:17:27

0:17:27

0:05:09

0:05:09

0:00:38

0:00:38

0:04:29

0:04:29

0:01:33

0:01:33

0:06:46

0:06:46

0:53:07

0:53:07

0:07:46

0:07:46

0:10:29

0:10:29

0:21:24

0:21:24

0:15:53

0:15:53