filmov

tv

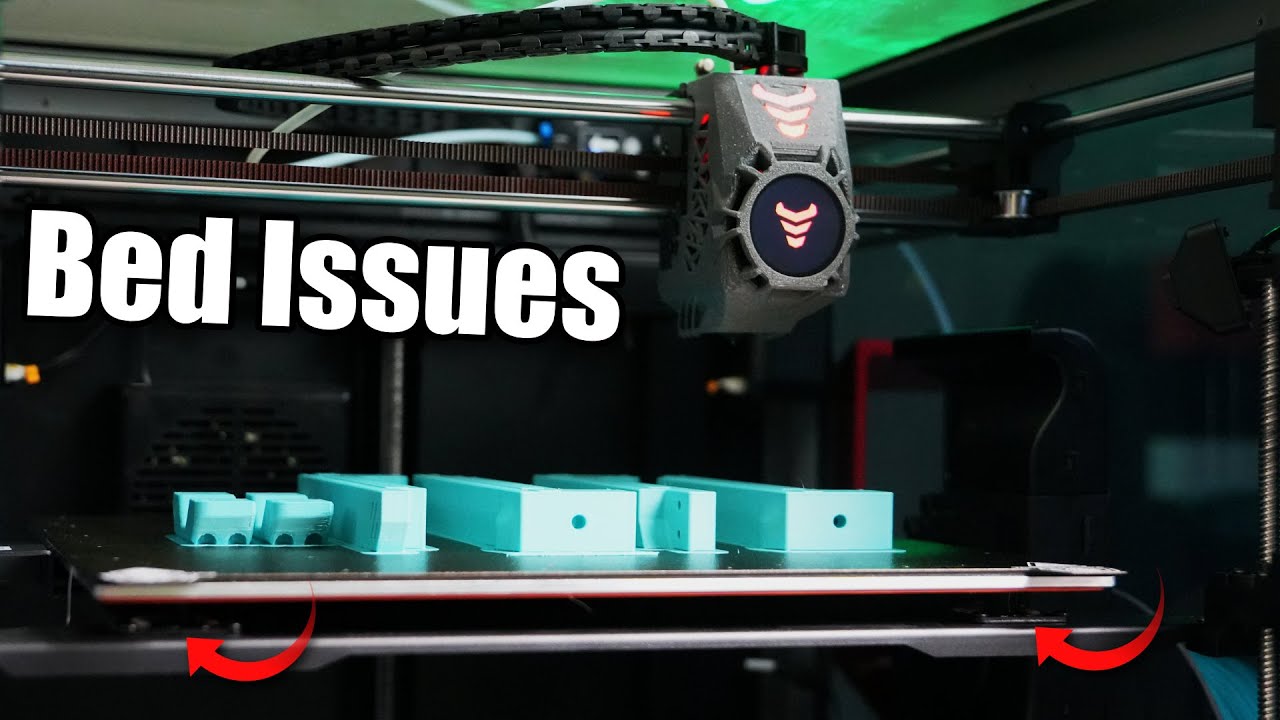

My Biggest Creality K1 Max Complaint (And Current Fix)

Показать описание

Love the channel? Consider supporting me on Patreon:

Get Great Filament From PolyMaker & Help Support The Channel:

Springs I Used (AFF):

K1 Klipper Installer Script:

NeedItMakeIt's video on fixing from the bottom:

Leveling Knobs model:

Screw Tilt Adjust documentation:

D3vil Burner Stream:

Find out more or pick up the Enderwire kit here (AFF):

ModBot Merch Store is now live! Get yours here:

In this video we dive into the Creality K1 Max. There is a lot that has been done well on this printer but the large and commonly warped bed can be problematic. I went down a bit of a rabbit hole with this and will share what I found and what worked to give me much better results.

(´∀`)♡ As an Amazon Associate I earn from qualifying purchases:

Lets Get Social!

Get Great Filament From PolyMaker & Help Support The Channel:

Springs I Used (AFF):

K1 Klipper Installer Script:

NeedItMakeIt's video on fixing from the bottom:

Leveling Knobs model:

Screw Tilt Adjust documentation:

D3vil Burner Stream:

Find out more or pick up the Enderwire kit here (AFF):

ModBot Merch Store is now live! Get yours here:

In this video we dive into the Creality K1 Max. There is a lot that has been done well on this printer but the large and commonly warped bed can be problematic. I went down a bit of a rabbit hole with this and will share what I found and what worked to give me much better results.

(´∀`)♡ As an Amazon Associate I earn from qualifying purchases:

Lets Get Social!

My Biggest Creality K1 Max Complaint (And Current Fix)

Creality K1 MAX Review - 6 Months Later...Is it STILL Good!?

THIS Fixes the Creality K1 Max

Creality K1 Max 3D Printer Review: Big + Fast Prints!

Dont Use Your Creality K1 Series Printer Until You've Seen THIS ** BONUS Mod At The End

Creality K1 Max Review - It's BIG, FAST & AMAZING!

SHATTERING Expectations - K1 Max Review

Is 3D printer modification dead? Creality K1 Max claims, it is..

Creality K1 Max Unboxing & Honest First Impressions - Bambu PRUSA Custom Build? Small Print farm

Watch This Before You Buy the Creality K1/K1 Max 3D Printer! | Unboxing & Hands-On Review

New mod for creality K1 & K1 max! Improve your creality K series 3D printer with this! K1 max mo...

Is the K1 Max better than the Bambu?

Creality K1 Max Review - A 3D Printer That is Big, Fast and Smart

Creality K1 Max In-Depth Review: A larger K1 with micro LiDar, AC Heated Bed, Ai Camera, air filter

My BIGGEST Print BY FAR! Creality Ferret Pro + K1 Max

Must upgrades for the Creality K1 Max - Part 1

17 Essential Upgrades to Enhance Your Creality K1

How Well Does ABS Filament Print on Modern 3D Printers? Creality K1, K1 Max & FlashForge Tests

Creality K1 MAX... it's a LIE... Buyer BEWARE!!, JUST DON'T BUY IT!

Introducing The Creality K1 Max! (And how is the K1 after 100+ hours?)

Creality K1 Max Review - Bigger, Faster, and Smarter!

Crazy Fast Out of The Box But With One Big Problem - Creality K1 3D Printer

The Best 3D Printer From Creality? K1C Review - This Is Not What I Expected

Creality JUST announced MULTI COLOR Printer and Add-on for your 3d Printer! Everything we know!!

Комментарии

0:10:44

0:10:44

0:09:31

0:09:31

0:15:25

0:15:25

0:17:20

0:17:20

0:10:14

0:10:14

0:13:38

0:13:38

0:18:49

0:18:49

0:12:11

0:12:11

0:09:24

0:09:24

0:12:13

0:12:13

0:09:25

0:09:25

0:20:26

0:20:26

0:09:26

0:09:26

0:31:17

0:31:17

0:14:19

0:14:19

0:00:41

0:00:41

0:18:26

0:18:26

0:14:59

0:14:59

0:03:11

0:03:11

0:13:06

0:13:06

0:19:20

0:19:20

0:07:40

0:07:40

0:18:18

0:18:18

0:02:30

0:02:30