filmov

tv

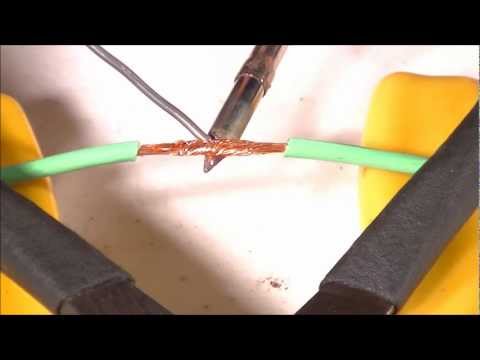

Soldering How To Part 1 - Finding the best solder for Your Projects

Показать описание

This is the first part of a multi part series on choosing the very best solder for our applications and learning how to solder. All of the basics will be covered to help you become a skilled solderer with the best solder, equipment, and techniques.

Thanks for watching!

Feel free to check AggressiveFun out at the following links (liking, subscribing, following, and commenting is encouraged and appreciated!!):

The following are Amazon Affiliate links to the equipment and materials that were used to produce this video. Amazon Affiliate links help us keep this blog up and running so if you are interested in making a purchase, please use one of the links below:

Solder:

Kester 275 No Clean Core K100LD Alloy .020" 24-9574-7610 (Favorite-No lead/no silver, AggressiveFun Package)

Kester 245 No Clean Core 63/37 .015" 24-6337-8853 Solder

(Favorite-My all time favorite, AggressiveFun Package)

Kester 44 Rosin Core 63/37 .010" 24-6337-0001 Solder

(Favorite-Smallest diameter, AggressiveFun Package)

Kester 44 Rosin Core 63/37 .031" .8mm 24-6337-0027 Solder

(Favorite-Most Popular, AggressiveFun Package)

Kester 44 Rosin Core 63/37 .020" 24-6337-0010 Solder

(AggressiveFun Package)

Kester 44 Rosin Core 63/37 .015" 24-6337-0007 Solder

(AggressiveFun Package)

Kester 44 Rosin Core 63/37 .025" 24-6337-0018 Solder

(AggressiveFun Package)

Kester 44 Rosin Core 63/37 .050"(1.27mm) 24-6337-0053 Solder

(AggressiveFun Package)

Alpha Telecore Plus No-Clean Solder Wire, P2, .032", SAC305

(Full 1lb Spool)

Equipment:

AmScope 7X-45X Simul-Focal Stereo Lockable Zoom Microscope on Dual Arm Boom Stand.

AmScope MU500-CK 5.0 MP USB Microscope Camera with Software and Calibration Kit, Compatible with Windows and Mac

AmScope LED-144W-ZK White Adjustable 144 LED Ring Light Illuminator for Stereo Microscope & Camera.

AmScope EG-SM Microscope Eyepiece Eyeshields or Eye-guards.

Video Equipment:

Canon VIXIA HF R700 (the model I use for video).

Canon VIXIA HF R800 (newer version).

Replacement Li-ion Battery and car charger adapter.

SanDisk Ultra 64GB microSDXC UHS-I Card with Adapter (Great deal!)

Sony 64GB SD Memory Card (the exact card I use)

Targus 3-Way Panhead Bubble Level Tripod (the exact one I used).

Canon VIXIA HF R700 Bundle deal with memory card, tripod, carry bag, extra battery, etc.

Thanks for watching!

Feel free to check AggressiveFun out at the following links (liking, subscribing, following, and commenting is encouraged and appreciated!!):

The following are Amazon Affiliate links to the equipment and materials that were used to produce this video. Amazon Affiliate links help us keep this blog up and running so if you are interested in making a purchase, please use one of the links below:

Solder:

Kester 275 No Clean Core K100LD Alloy .020" 24-9574-7610 (Favorite-No lead/no silver, AggressiveFun Package)

Kester 245 No Clean Core 63/37 .015" 24-6337-8853 Solder

(Favorite-My all time favorite, AggressiveFun Package)

Kester 44 Rosin Core 63/37 .010" 24-6337-0001 Solder

(Favorite-Smallest diameter, AggressiveFun Package)

Kester 44 Rosin Core 63/37 .031" .8mm 24-6337-0027 Solder

(Favorite-Most Popular, AggressiveFun Package)

Kester 44 Rosin Core 63/37 .020" 24-6337-0010 Solder

(AggressiveFun Package)

Kester 44 Rosin Core 63/37 .015" 24-6337-0007 Solder

(AggressiveFun Package)

Kester 44 Rosin Core 63/37 .025" 24-6337-0018 Solder

(AggressiveFun Package)

Kester 44 Rosin Core 63/37 .050"(1.27mm) 24-6337-0053 Solder

(AggressiveFun Package)

Alpha Telecore Plus No-Clean Solder Wire, P2, .032", SAC305

(Full 1lb Spool)

Equipment:

AmScope 7X-45X Simul-Focal Stereo Lockable Zoom Microscope on Dual Arm Boom Stand.

AmScope MU500-CK 5.0 MP USB Microscope Camera with Software and Calibration Kit, Compatible with Windows and Mac

AmScope LED-144W-ZK White Adjustable 144 LED Ring Light Illuminator for Stereo Microscope & Camera.

AmScope EG-SM Microscope Eyepiece Eyeshields or Eye-guards.

Video Equipment:

Canon VIXIA HF R700 (the model I use for video).

Canon VIXIA HF R800 (newer version).

Replacement Li-ion Battery and car charger adapter.

SanDisk Ultra 64GB microSDXC UHS-I Card with Adapter (Great deal!)

Sony 64GB SD Memory Card (the exact card I use)

Targus 3-Way Panhead Bubble Level Tripod (the exact one I used).

Canon VIXIA HF R700 Bundle deal with memory card, tripod, carry bag, extra battery, etc.

Комментарии

0:33:07

0:33:07

0:16:11

0:16:11

0:07:33

0:07:33

0:27:14

0:27:14

0:34:19

0:34:19

0:13:45

0:13:45

0:18:30

0:18:30

0:25:10

0:25:10

0:18:10

0:18:10

0:06:17

0:06:17

0:19:15

0:19:15

0:07:18

0:07:18

0:19:25

0:19:25

0:17:33

0:17:33

0:14:06

0:14:06

0:22:09

0:22:09

0:07:44

0:07:44

0:18:13

0:18:13

0:04:59

0:04:59

0:11:56

0:11:56

0:09:14

0:09:14

0:35:03

0:35:03

0:00:16

0:00:16

0:33:18

0:33:18