filmov

tv

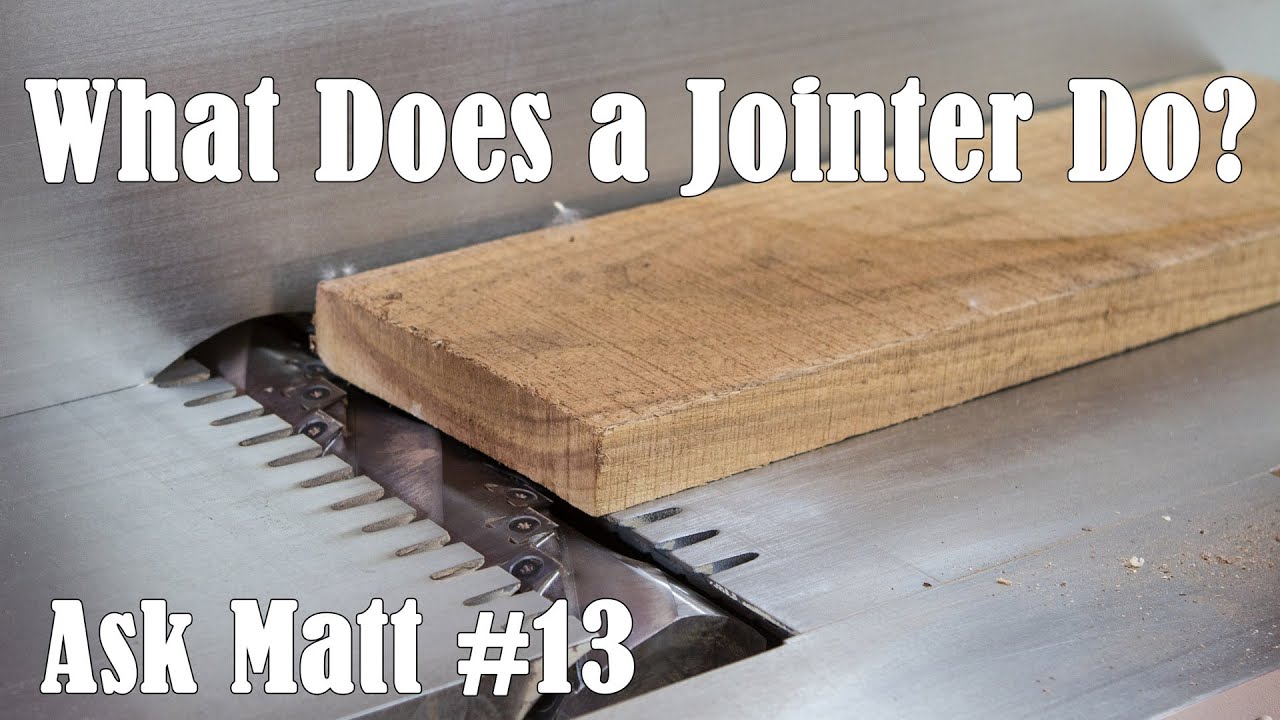

What Does a Jointer Do? - Ask Matt #13

Показать описание

A jointer is a very important tool in a woodworking shop. Its job is to set the foundation for all future work you will be doing with a board. Being able to properly mill a board flat and true is a fundamental task in woodworking because flat work pieces lead to more precise and consistent joinery in your projects.

This is the thirteenth episode of my Ask Matt series. If you have a topic suggestion please feel free to send it to me.

This is the thirteenth episode of my Ask Matt series. If you have a topic suggestion please feel free to send it to me.

Jointer Basics – WOOD magazine

What Does a Jointer Do? - Ask Matt #13

How to Use a Jointer

Planer VS Jointer: What's the Difference? | Woodshop 101

Jointer vs Planer: What Does Each One Do?

Jointers For Beginners - Use Tips, Tricks, Buying Advice and Safety

How to Use a Jointer 5 Ways | What is a Jointer | Woodworking

Why Buy a Jointer for #woodworking

Why do they call it a jointer when it planes wood?

Jointer or Planer? Which One Do You Buy First?

Why the Jointer Can't Do it All

How a Jointer Works

dont waste money on a jointer

Why jointers/planers do NOT make boards flat + square

6 Features to Check Before Buying a Jointer | Woodworking

What does a jointer do?

What is the Difference between a JOINTER and a THICKNESSER!?

Tools you DON'T need: Jointer vs Planer vs Drum sander

Do you need a Jointer AND planer?🤔 #woodworking #shorts #diy #handmade

Why your DeWalt planer is not a jointer #planer #woodworking

Awesome Woodworking Hack – How to Transform Your Router Table into a Jointer!

What Does a Jointer Do?

Here's What a Wahuda Jointer Is Actually Like After 2 Years

2 Ways To Joint Boards without a Jointer #shorts

Комментарии

0:04:06

0:04:06

0:15:08

0:15:08

0:01:00

0:01:00

0:06:10

0:06:10

0:07:01

0:07:01

0:15:13

0:15:13

0:04:00

0:04:00

0:00:34

0:00:34

0:12:32

0:12:32

0:03:21

0:03:21

0:03:21

0:03:21

0:00:23

0:00:23

0:00:58

0:00:58

0:07:13

0:07:13

0:08:33

0:08:33

0:00:22

0:00:22

0:17:42

0:17:42

0:08:41

0:08:41

0:00:28

0:00:28

0:00:26

0:00:26

0:00:46

0:00:46

0:00:12

0:00:12

0:07:53

0:07:53

0:00:47

0:00:47