filmov

tv

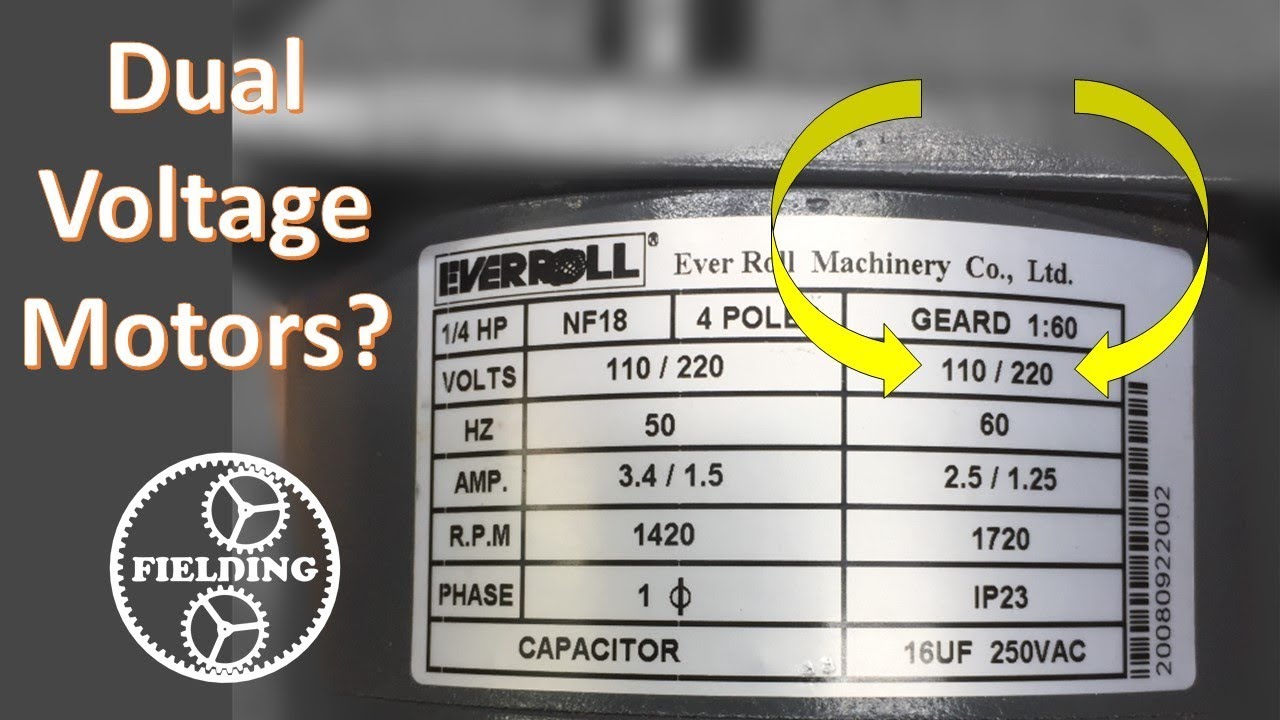

Dual Voltage Motors, How They Work, And Wiring Them Without The Wire Labels. #059

Показать описание

How Dual Voltage Motors Work, and How to Wire them even without the wire labels. I have received several requests to cover this topic.

If you want to chip in a few bucks to support more content like this, please visit my patreon page.

Final Note:

PLEASE UNDERSTAND...I receive hundreds of messages on all platforms asking for advice, and help with projects. At this volume, I simply can't do one on one advice.

If you want to chip in a few bucks to support more content like this, please visit my patreon page.

Final Note:

PLEASE UNDERSTAND...I receive hundreds of messages on all platforms asking for advice, and help with projects. At this volume, I simply can't do one on one advice.

Dual Voltage Motors, How They Work, And Wiring Them Without The Wire Labels. #059

Dual Voltage Motor Connections

Dual Voltage Motors Introduction and Terminal Identification

Delta Dual Voltage Motor - High Voltage Connection

Delta Dual Voltage Motor - Low Voltage Connection

Dual Voltage and Part Start 3-Phase Motors

Wye Dual Voltage Motor - High Voltage Connection

Wye Dual Voltage Motor - Low Voltage Connection

Downgraded!! Senada Herald 750W Budget Ebike Review

Percent Slip Dual Voltage Motors

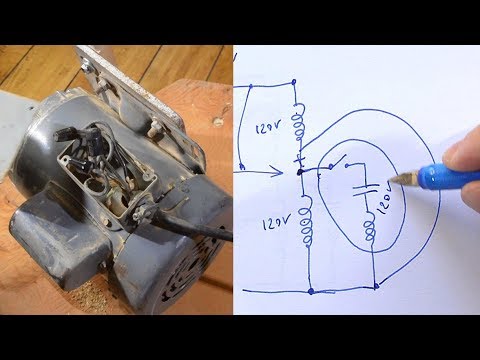

Rewiring a motor from 240 volts to 120 volts

DUAL VOLTAGE MOTOR WIRING

Dual Voltage 3 Phase Motor Wiring (How To Wire A Multi Voltage 3 Phase Motor) Simple & Easy!

Wiring a 3 phase dual voltage motor simple way

Motor Minute™ Technical Tip: Evergreen® EM Dual Voltage Motors

Wiring Connection and Operation of Dual Voltage Motor

Industrial Lab 1A & 1B- Dual voltage motor, single phase

Single Phase Dual Voltage Motor Wiring Project

Industrial Lab 1A & 1B- Dual voltage motor, single phase

Rewiring Motors for 110V / 220V

Industrial Lab 1A & 1B- Dual voltage motor, single phase

Single Phase Electric Motor Wiring Tutorial: Baldor, WEG, Leeson

How to wire a 3 phase motor

Dual Voltage, 3 Phase, 9 Lead Wye Motor Connections #1

Комментарии

0:09:39

0:09:39

0:16:13

0:16:13

0:04:32

0:04:32

0:02:33

0:02:33

0:03:59

0:03:59

0:09:35

0:09:35

0:02:25

0:02:25

0:02:49

0:02:49

0:37:35

0:37:35

0:11:21

0:11:21

0:04:41

0:04:41

0:15:45

0:15:45

0:11:18

0:11:18

0:01:31

0:01:31

0:02:15

0:02:15

0:27:30

0:27:30

0:00:22

0:00:22

0:57:18

0:57:18

0:00:38

0:00:38

0:16:06

0:16:06

0:00:22

0:00:22

0:07:52

0:07:52

0:06:18

0:06:18

0:24:15

0:24:15