filmov

tv

Machining the Bed on the Flex CNC

Показать описание

In this video we take the final steps of the Flex CNC mill installation. Typically this is is done by @FlexMachineTools prior to shipping out to the customer but I asked if we could do this in the shop to help getting a little more training and seat time on the machine. Everything turned out great and the machine is now ready for some work and projects. #abom79 #flexcnc #flexmachinetools #cnc #cncmachine #longbedmill

Visit my second Youtube channel where you can follow our travels, camping, RVing, cooking, and bbq!

Visit my second Youtube channel where you can follow our travels, camping, RVing, cooking, and bbq!

Machining the Bed on the Flex CNC

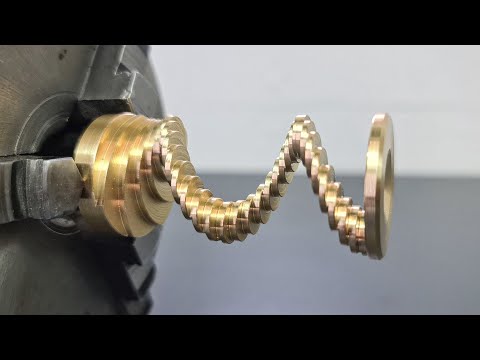

Impressive CNC Lathe Machine Turning

Making a Crazy Part on the Lathe - Manual Machining

Lathe Machine Opretion Center #technical #tech #iti #technology #nagar technical

Sawmill Drive Roller | Machining & Broaching

Machining a Miniature Lathe - The Bed and Legs - (A)

OUT of POCKET... #shorts

This Machine Tucks You PERFECTLY Into Bed ! 🤯

MDF tape machine. #woodworking #wooden #diywoodworking #diy #mdf #tool #cnccut #machine #diywood

Plastoseal Hand Sealer 500mm / 20' Hand sealing machine #plasticbagsealer #sealingmachine

Easy Low Profile Side Clamps For The Milling Machine

How to make a Sheet Bending Machine ''Crocodile''

Making a Bed Leg on Lathe Machine | Full Machining Process | Turning, Drilling Threading'#tran...

Machining a Miniature Lathe - The Bed and Legs - (B)

Wood Saw Machine Tool #Gadget #Gadgets 😉SUBSCRIBE PLEASE!👇👇👇 #shorts

Will A 3D Printed Quarter Work In A Gumball Machine? #shorts

I took apart the BED to make this MIRACLE MACHINE. DIY

Finally the machinist solution to this old problem 🤓 #cnc #machining #cncfun #tools #bohren #howto...

Land Cultivator Agriculture machine | Bed Maker Machine | BEST POWER TILLER - MINI POWER TILLER

Hydraulic press machine working | 80 ton Hydraulic power press machine price | O.P.S UDYOG, Batala

MRI Machine and Metal

Belajar mobil - tips tarik rem tangan/handbrake manual cukup mudah

#cricket #bowling #machine

Couch Got Pressed in Machine 😳

Комментарии

0:39:21

0:39:21

0:00:10

0:00:10

0:04:15

0:04:15

0:00:21

0:00:21

0:45:30

0:45:30

0:37:07

0:37:07

0:02:51

0:02:51

0:00:36

0:00:36

0:00:15

0:00:15

0:00:15

0:00:15

0:07:29

0:07:29

0:15:18

0:15:18

0:00:31

0:00:31

0:41:25

0:41:25

0:00:19

0:00:19

0:00:30

0:00:30

0:32:01

0:32:01

0:00:15

0:00:15

0:02:00

0:02:00

0:00:15

0:00:15

0:00:12

0:00:12

0:00:08

0:00:08

0:00:13

0:00:13

0:00:16

0:00:16