filmov

tv

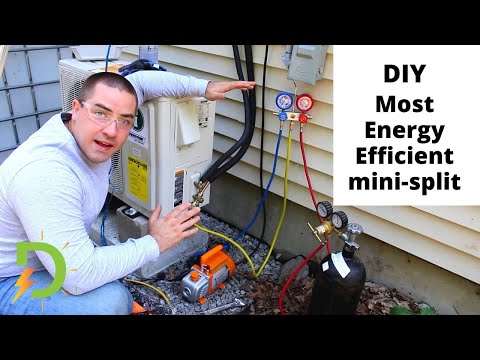

DIY Mini Split Install - All the Things Nobody Shows You

Показать описание

Installing a Mini Split is totally doable, but there are several things that all of the other videos gloss over. This is a TRUE, STEP BY STEP tutorial, baby. #minisplit #tosot #heatingairconditioning

🎬 CHECK OUT THESE RELATED VIDEOS! 🎬

📦 PRODUCTS IN THIS VIDEO 📦

USE COUPON CODE 💰"LRN2DIY"💰 to save $100 on TOSOT orders!

👍 WANT TO HELP SUPPORT THIS CHANNEL? 👍

👕 LRN2DIY SHIRTS, HOODIES & MORE 👚

📸 MY FILMING GEAR 📸

🕶 SOCIAL MEDIA 🕶

📲 MORE DIY GOODNESS 📲

Check out our many projects and plans at

📲 WANT TO LEARN MORE ABOUT 3D PRINTING? 📲

All things 3D Printing at The 3D Printing Zone

📚 TWO FREE AUDIOBOOKS! 📚

🎬 CHECK OUT THESE RELATED VIDEOS! 🎬

📦 PRODUCTS IN THIS VIDEO 📦

USE COUPON CODE 💰"LRN2DIY"💰 to save $100 on TOSOT orders!

👍 WANT TO HELP SUPPORT THIS CHANNEL? 👍

👕 LRN2DIY SHIRTS, HOODIES & MORE 👚

📸 MY FILMING GEAR 📸

🕶 SOCIAL MEDIA 🕶

📲 MORE DIY GOODNESS 📲

Check out our many projects and plans at

📲 WANT TO LEARN MORE ABOUT 3D PRINTING? 📲

All things 3D Printing at The 3D Printing Zone

📚 TWO FREE AUDIOBOOKS! 📚

DIY Mini Split Install - All the Things Nobody Shows You

DIY Mini Split Install: 3 Regrets After 1 Year of Use

Complete DIY Mini Split Installation | New Mr Cool 4th Gen Unit

DIY Mini Split Install: Mr. Cool, Multi Zone System.

DIY Ductless Mini Split Install - MrCool Unit

Mini Split Install So Easy A Handyman Can Do It | No Need For HVAC Company | THE HANDYMAN |

I Saved $2000 Installing My Own Mini Split

DIY Mini-Split Install: I did NOT expect this...

How to Install a DIY Mini Split Air Conditioning and Heat Unit. MR COOL 24K Split Unit

This MINI-Split AC System Changed My Life | Learn How To Install One Yourself

DIY Mini Split Step by Step Install: Save Thousands of Dollars...

DIY Mini-Split Heat Pump, Full Installation, 2021

Budget Mini Split Installation for Beginners! w/ Vacuum Pump and Gauges

Install your own AIR CONDITIONING in 4 HOURS! DIY Mini Split MR COOL

DIY MULTI-ZONE Ductless MINI SPLIT Installation in New Construction!

How to Install a Ductless Mini-Split Air Conditioner | This Old House

Mr Cool DIY 4th Gen 12000btu Mini Split Full Install

How to Install a Wall-Mounted Mini-Split | Ask This Old House

Installing My Own Mini-Split Heat Pump, DIY

How To Make an R410A Flare for a Mini Split AC Unit Installation

HVAC Pros Don't want you to See This! Pioneer Mini Split DIY INSTALL

How To Install A MrCool DIY Ductless Mini Split YOURSELF! - FAST and EASY!

MrCool DIY Mini Split Install

Mr Cool DIY Mini Split (1 Year Review)

Комментарии

0:33:25

0:33:25

0:08:11

0:08:11

0:18:43

0:18:43

0:53:28

0:53:28

0:09:44

0:09:44

0:16:37

0:16:37

0:16:45

0:16:45

0:11:16

0:11:16

0:15:01

0:15:01

0:14:46

0:14:46

0:13:57

0:13:57

1:08:07

1:08:07

0:19:47

0:19:47

0:10:13

0:10:13

0:17:14

0:17:14

0:07:09

0:07:09

0:18:52

0:18:52

0:08:25

0:08:25

0:15:44

0:15:44

0:12:11

0:12:11

0:16:34

0:16:34

0:45:02

0:45:02

0:18:42

0:18:42

0:06:51

0:06:51