filmov

tv

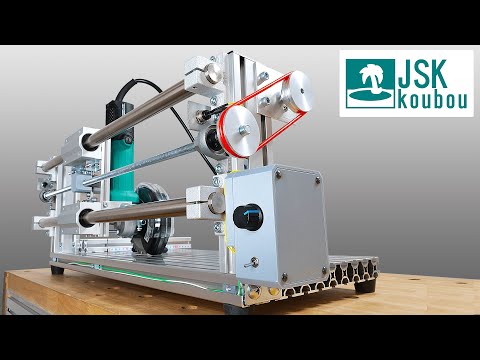

Amazing precision of a DIY Wire EDM machine

Показать описание

This video demonstrates what kind of precision is possible on a DIY wire EDM machine.

Amazing precision of a DIY Wire EDM machine

Crafting Precision Dowels: Explore the Adjustable Dowel Maker for Woodworking Excellence!

Small CNC machining tools- Good tools and machinery make work easy

Amazing device to cut metal with high precision

How to join 2 wooden bars with amazing precision #construction #diy

Screw it! Ultra-Precision for Shopmade Tools

Woodworking tips and tricks! How to make a reliable corner joint for boards of different sizes

#amazing ideas #lathe #becreative

Double - Slot Six - Sided Light Box: Precision Engineering in Action#shorts #aluminum #chinafactory

Watch Metal Fill an Eggshell in Seconds! #shorts #viralvideo #restoration #aluminum #metal

Mini Precision Electric Screwdriver for Gadgets, Watches, Computers, Etc. | #diycrafts

Dieses Werkzeug ist einfach nur GENIAL!

Handheld Laser Welding Machine | Precision Welding with Advanced Laser Technology

* 'The Smallest Lock Ever? Miniature Engineering Masterpiece!'

Super DIY! How to Make A Chain Fidget Spinner

Precision Metal Spinner Sprocket Chain Fidget Toy - The Ultimate Stress-Relieving Tool

Amazing Jigsaw Guide #Shorts

dc motor | speed control | Amazing Experiment Projects

He Built a Designer Table from a Tree Root and a Desert Rock!

📏 Measuring Tape Hack For Perfect Accuracy! | DIY Tool Upgrade in 2 Mins 🔧

Multi Sliding Table Saw with Precision Techniques in Action

Mini Drill Machine: Compact Power for Precision! 🔧⚙️

Freedomandfeathers - Shooting an arrow through an Axe (Archery)

Throw Cards Like a Pro! 😱

Комментарии

0:25:20

0:25:20

0:00:10

0:00:10

0:00:13

0:00:13

0:23:56

0:23:56

0:00:46

0:00:46

0:00:59

0:00:59

0:00:16

0:00:16

0:01:00

0:01:00

0:00:22

0:00:22

0:00:20

0:00:20

0:00:27

0:00:27

0:00:16

0:00:16

0:00:18

0:00:18

0:00:09

0:00:09

0:00:16

0:00:16

0:00:16

0:00:16

0:01:00

0:01:00

0:00:17

0:00:17

0:01:00

0:01:00

0:00:15

0:00:15

0:00:38

0:00:38

0:00:08

0:00:08

0:00:29

0:00:29

0:00:23

0:00:23