filmov

tv

3 Ways to Make Sulfur Dioxide Gas

Показать описание

In this video, I'll be demonstrating three methods to produce sulfur dioxide gas. Sulfur dioxide, while undesirable on its own due to its toxicity and environmental impact, serves as a crucial precursor for various chemical processes, including the production of sulfuric acid. These methods have been showcased in previous videos, but I've compiled them here for easy reference.

Method 1: Burning Sulfur

The most cost-effective approach involves burning sulfur. Elemental sulfur, often used in gardening and pest control, is readily available. By burning it and capturing the resulting sulfur dioxide, we can utilize it for various reactions. A gas capture setup is essential, comprising a metal funnel over the burning sulfur, connected to a coil of copper tubing to cool the gas, and finally linked to a reaction flask using plastic tubing. Vacuum assistance is used to pull the gas into the apparatus, eliminating the need for a sealed combustion chamber.

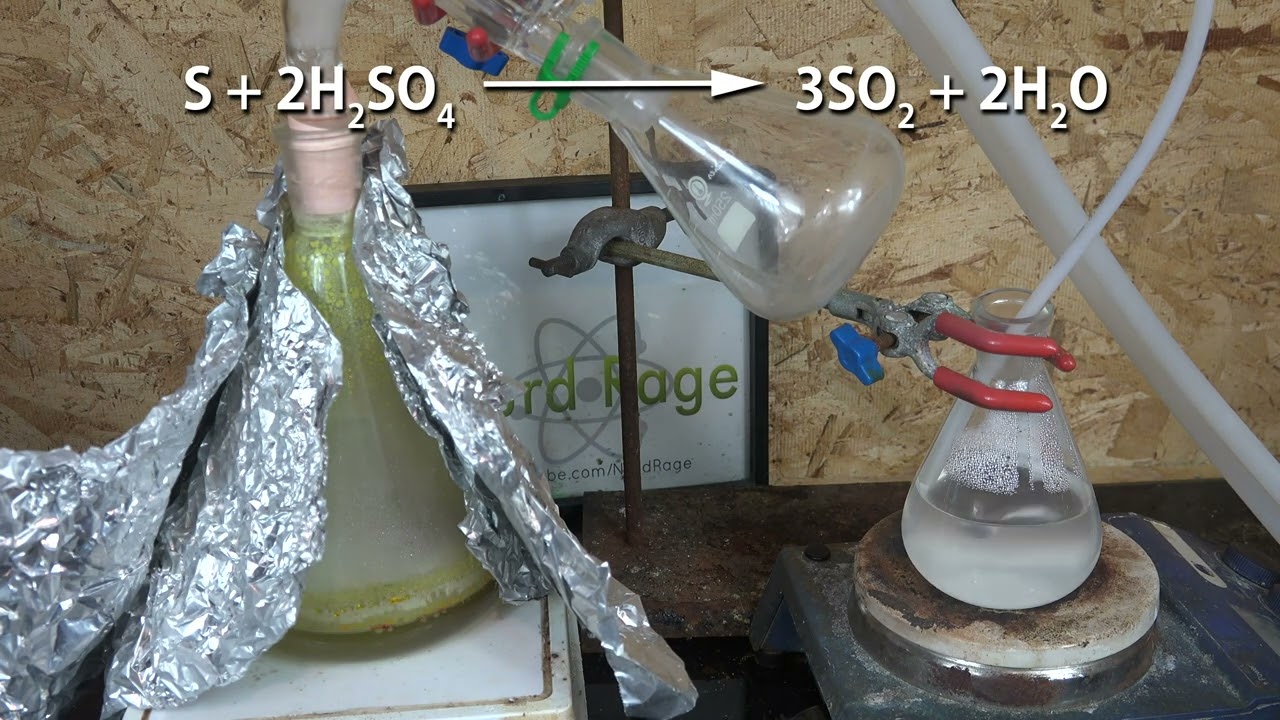

Method 2: Sulfuric Acid Decomposition

This method involves adding elemental sulfur to concentrated sulfuric acid within a sealed distillation setup. The sulfuric acid decomposes the sulfur to produce sulfur dioxide and water. While this approach yields relatively pure sulfur dioxide, it is slow and inefficient for amateur chemists. Moreover, the risk of dealing with boiling hot sulfuric acid makes it impractical for most.

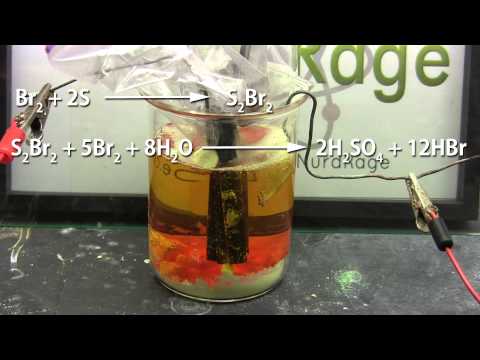

Method 3: Sodium Metabisulfite Acidification

The most convenient yet costly method involves sodium metabisulfite and hydrochloric acid. A generator is set up with water, sodium metabisulfite, and hydrochloric acid. Upon opening a valve, the hydrochloric acid reacts with the sodium metabisulfite to instantly produce sulfur dioxide gas. This method offers convenience, immediate gas production, and purity, making it preferable for many applications. Sodium metabisulfite, found online and used in food preservation, is readily available for purchase.

In summary, these three methods provide options for generating sulfur dioxide gas, each with its advantages and drawbacks. The choice of method depends on factors like cost, convenience, purity, and safety considerations for specific applications.

Donate to NurdRage!

Method 1: Burning Sulfur

The most cost-effective approach involves burning sulfur. Elemental sulfur, often used in gardening and pest control, is readily available. By burning it and capturing the resulting sulfur dioxide, we can utilize it for various reactions. A gas capture setup is essential, comprising a metal funnel over the burning sulfur, connected to a coil of copper tubing to cool the gas, and finally linked to a reaction flask using plastic tubing. Vacuum assistance is used to pull the gas into the apparatus, eliminating the need for a sealed combustion chamber.

Method 2: Sulfuric Acid Decomposition

This method involves adding elemental sulfur to concentrated sulfuric acid within a sealed distillation setup. The sulfuric acid decomposes the sulfur to produce sulfur dioxide and water. While this approach yields relatively pure sulfur dioxide, it is slow and inefficient for amateur chemists. Moreover, the risk of dealing with boiling hot sulfuric acid makes it impractical for most.

Method 3: Sodium Metabisulfite Acidification

The most convenient yet costly method involves sodium metabisulfite and hydrochloric acid. A generator is set up with water, sodium metabisulfite, and hydrochloric acid. Upon opening a valve, the hydrochloric acid reacts with the sodium metabisulfite to instantly produce sulfur dioxide gas. This method offers convenience, immediate gas production, and purity, making it preferable for many applications. Sodium metabisulfite, found online and used in food preservation, is readily available for purchase.

In summary, these three methods provide options for generating sulfur dioxide gas, each with its advantages and drawbacks. The choice of method depends on factors like cost, convenience, purity, and safety considerations for specific applications.

Donate to NurdRage!

Комментарии