filmov

tv

COMPRESSION RATIO: HOW to CALCULATE, MODIFY and CHOOSE the BEST one - BOOST SCHOOL #10

Показать описание

In today's video we're talking about your engine's compression ratio. First we'll explain the theory behind the compression ratio, so what it is and how it influences the performance and efficiency of your engines. After that we will dive into the practical side of things and we will see how to calculate and modify your compression ratio and finally we'll talk about choosing the best compression ratio for your application. So, let's get started.

Now when we say compression ratio we're actually referring to the static compression ratio of the engine, and that is the ratio between the largest and smallest volume of your cylinder. In other words it's the ratio between the cylinder volume when the piston is at bottom dead center and the cylinder volume when the piston is at top dead center.

Your compression ratio, as the name implies, determines how much the air and fuel mixture inside your cylinder gets squeezed and compressed. The higher your compression ratio the closer the air and fuel molecules are brought together which means that we allow combustion to occur more effectively and more rapidly which ensures that the air fuel mixture is burned more thoroughly. Iin general a higher combustion ratio is achieved either by reducing the size of the combustion chamber or by bringing the piston closer to the combustion chamber. By doing this we of course bring the piston closer to the heart of the cobmsution or the source of energy which allows more of this energy to be transfered onto the piston and turned into piston movement or mechanical energy. In other words a higher combustion ratio can improve both power and efficiency.

So the more the better right? Well as with all things there's a sensible limit and you can actually have too much of a good thing.

Because a higher compression ratio contributes to a more thorough burn of the air fuel mixture it also increases combustion temperatures. The more compressed the mixture the better it burns and the better it burns the hotter it burns. The upside of this is of course more power potential and more efficiency but the downside is that the engine will run hotter and will have increased nitrogen oxide emissions.

Higher combustion temperatures lead to more nitrogen oxide emissions which is one of the main reasons why more modern diesel engines that have a EURO 6 emissions standard run on average lower compression than their predecessors from a decade or two ago.

But one of the main limiting factors when it comes to compression in spark ignition engines is of course knock. When you compresses gasses they heat up, air is of course a gas and if you compress it too much it can get hot enough to ignite gasoline fuel before it's actually reached by the expanding flame front created by the spark plug. This is called knock. Obviously a higher compression ratio increases the chances of knock and thus limits the ratio of compression a gasoline engine can have. This is especially true for forced induction engines which send already compressed air into the engine.

Okay, so that's the basic theory now let's move onto the practical side of things. So what determines your engine's compression ratio?

It's actually seven things:

1. Your bore

2. Your stroke

3. The thickness of your compressed head gasket

4. The bore of your head gasket

5. The distance between your piston top and your block deck

6. The volume of your piston dish or dome

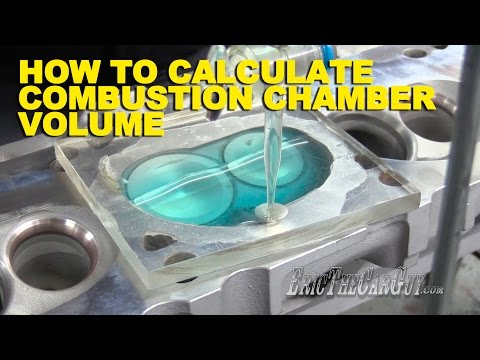

7. And your combustion chamber volume

So how do you calculate it? Well there are formulas but the advent of the internet allows us to be lazy and just plug everything into readily available free to use online compression ratio calculators.

When it comes to changing our compression ratio here's a basic run-down.

Increased bore - increased compression ratio

Increased stroke - increased compression ratio

Thicker head gasket - reduces compression ratio

Thinner head gasket - increases compression ratio

Decking the block - increases compression ratio

Cutting the head - increases compression ratio

Removing material from the combustion chamber - reduces compression ratio

Domed pistons - increase compression ratio

Dished pistons - reduce compression ratio

A special thank you to my patrons:

Daniel

Peter Della Flora

Daniel Morgan

William

Richard Caldwell

Pepe

Brian Durning

Brian Alvarez

Dave Westwood

Joe C

#d4a #boostschool #compressionratio

00:00 What is compression ratio and how it works

04:20 How to calculate compression ratio

06:42 How to change it

09:37 Choosing the optimal one for your application

Now when we say compression ratio we're actually referring to the static compression ratio of the engine, and that is the ratio between the largest and smallest volume of your cylinder. In other words it's the ratio between the cylinder volume when the piston is at bottom dead center and the cylinder volume when the piston is at top dead center.

Your compression ratio, as the name implies, determines how much the air and fuel mixture inside your cylinder gets squeezed and compressed. The higher your compression ratio the closer the air and fuel molecules are brought together which means that we allow combustion to occur more effectively and more rapidly which ensures that the air fuel mixture is burned more thoroughly. Iin general a higher combustion ratio is achieved either by reducing the size of the combustion chamber or by bringing the piston closer to the combustion chamber. By doing this we of course bring the piston closer to the heart of the cobmsution or the source of energy which allows more of this energy to be transfered onto the piston and turned into piston movement or mechanical energy. In other words a higher combustion ratio can improve both power and efficiency.

So the more the better right? Well as with all things there's a sensible limit and you can actually have too much of a good thing.

Because a higher compression ratio contributes to a more thorough burn of the air fuel mixture it also increases combustion temperatures. The more compressed the mixture the better it burns and the better it burns the hotter it burns. The upside of this is of course more power potential and more efficiency but the downside is that the engine will run hotter and will have increased nitrogen oxide emissions.

Higher combustion temperatures lead to more nitrogen oxide emissions which is one of the main reasons why more modern diesel engines that have a EURO 6 emissions standard run on average lower compression than their predecessors from a decade or two ago.

But one of the main limiting factors when it comes to compression in spark ignition engines is of course knock. When you compresses gasses they heat up, air is of course a gas and if you compress it too much it can get hot enough to ignite gasoline fuel before it's actually reached by the expanding flame front created by the spark plug. This is called knock. Obviously a higher compression ratio increases the chances of knock and thus limits the ratio of compression a gasoline engine can have. This is especially true for forced induction engines which send already compressed air into the engine.

Okay, so that's the basic theory now let's move onto the practical side of things. So what determines your engine's compression ratio?

It's actually seven things:

1. Your bore

2. Your stroke

3. The thickness of your compressed head gasket

4. The bore of your head gasket

5. The distance between your piston top and your block deck

6. The volume of your piston dish or dome

7. And your combustion chamber volume

So how do you calculate it? Well there are formulas but the advent of the internet allows us to be lazy and just plug everything into readily available free to use online compression ratio calculators.

When it comes to changing our compression ratio here's a basic run-down.

Increased bore - increased compression ratio

Increased stroke - increased compression ratio

Thicker head gasket - reduces compression ratio

Thinner head gasket - increases compression ratio

Decking the block - increases compression ratio

Cutting the head - increases compression ratio

Removing material from the combustion chamber - reduces compression ratio

Domed pistons - increase compression ratio

Dished pistons - reduce compression ratio

A special thank you to my patrons:

Daniel

Peter Della Flora

Daniel Morgan

William

Richard Caldwell

Pepe

Brian Durning

Brian Alvarez

Dave Westwood

Joe C

#d4a #boostschool #compressionratio

00:00 What is compression ratio and how it works

04:20 How to calculate compression ratio

06:42 How to change it

09:37 Choosing the optimal one for your application

Комментарии

0:15:50

0:15:50

0:04:21

0:04:21

0:03:22

0:03:22

0:03:03

0:03:03

0:03:03

0:03:03

0:16:34

0:16:34

0:20:17

0:20:17

0:02:49

0:02:49

0:06:54

0:06:54

0:35:53

0:35:53

0:12:59

0:12:59

0:13:50

0:13:50

0:39:40

0:39:40

0:08:05

0:08:05

0:04:10

0:04:10

0:21:53

0:21:53

0:05:45

0:05:45

0:37:45

0:37:45

0:06:49

0:06:49

0:25:57

0:25:57

0:00:43

0:00:43

0:09:12

0:09:12

0:10:19

0:10:19

0:18:43

0:18:43