filmov

tv

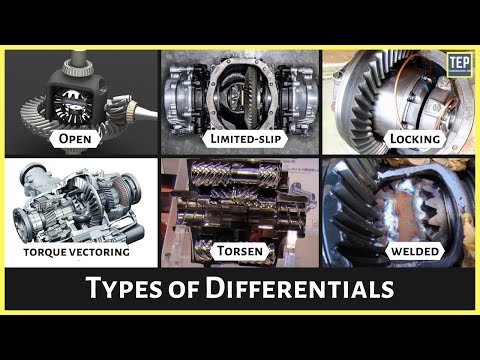

Understanding Differences in Automotive Differentials

Показать описание

See 11 different types of automotive differentials and learn how they work. This video is intended for students in the AUSV 1220 Manual Drivetrain class at Weber State University with Professor John D. Kelly.

CORRECTIONS:

1. The differential I called a "Detroit Locker" is not a Detroit Locker. It is just an Eaton Posi Limited Slip differential. A Detroit Locker uses dog teeth and is a truly locking differential. Thank you goes out to Keith MacDonald for catching my error.

2. I did not adequately explain how the clutch packs of a limited-slip differential are applied. The simple rotation of the side gears versus the differential pinion gears does not cause clutch packs to apply, otherwise, the clutches would apply when turning corners at low load (low torque). Torque from the engine (or another propulsion source) is necessary. The more torque you supply to the differential side gears the higher the force on the angled (ramped) teeth, the higher the force on the clutch packs. Thank you to several viewers for pointing out my omission.

4. I incorrectly described the operation of the original 1956 Dana limited-slip differential. The pinion pins on the original Dana differential have tapered ends. The pins sit in four V-shaped ramps in the differential case. Under a load, the differential case applies rotational torque to the pinion pins causing them to slide up the V-shaped ramps. This action applies outward force to the side gears and the clutch packs. Thank you to several viewers for pointing out my error.

TIMELINE

0:00 Start

0:08 Introduction

0:32 Open Differential

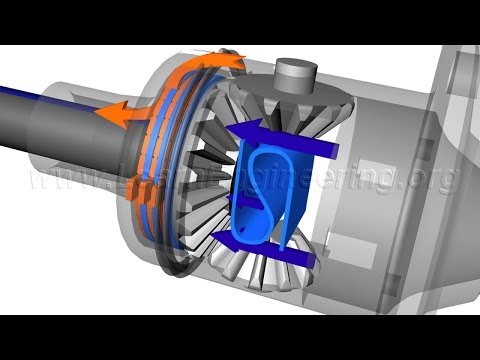

3:55 Power flow through a differential

6:51 Side gear backlash control

9:09 Differential Demonstration

10:21 MUST SEE Differential Equations

13:12 Automotive differential history

14:44 Dana Corporation's 1955 invention of the automatic locking differential

15:33 Various names for Dana's locking differential

17:23 See a 1963 Chevrolet positraction differential with clutch packs

24:00 How rotating gears apply a clutch pack

26:35 Why limited-slip additive may be required for a clutch-type differential

28:46 See a 1970s era GM positraction differential with clutch packs

29:40 See a 1984 Chevrolet Corvette Limited-Slip differential with clutch packs

30:02 See a 2012 Eaton Posi Limited-Slip differential with clutch packs

34:00 MUST SEE See a worn out 2010 Chevrolet Camaro SS Limited-Slip differential with clutch packs

38:00 See a broken 2005 Jeep Wrangler Rubicon Torsen Type B style limited-slip differential with an air locker

43:51 MUST SEE See the pieces of a Torsen Type B style differential and see how it works

48:03 See a 2002 Toyota Tacoma Electric Locking Differential

51:00 See the Eaton Detroit Trutrac (Similar to the Torsen Type B differential design)

49:55 See a spool with no differential action

53:40 See a Mini-Spool and how to install it

56:35 See the Eaton Locker and learn how it works

1:00:45 Final wrapup

ABOUT US:

DONATE TO OUR DEPARTMENT

CORRECTIONS:

1. The differential I called a "Detroit Locker" is not a Detroit Locker. It is just an Eaton Posi Limited Slip differential. A Detroit Locker uses dog teeth and is a truly locking differential. Thank you goes out to Keith MacDonald for catching my error.

2. I did not adequately explain how the clutch packs of a limited-slip differential are applied. The simple rotation of the side gears versus the differential pinion gears does not cause clutch packs to apply, otherwise, the clutches would apply when turning corners at low load (low torque). Torque from the engine (or another propulsion source) is necessary. The more torque you supply to the differential side gears the higher the force on the angled (ramped) teeth, the higher the force on the clutch packs. Thank you to several viewers for pointing out my omission.

4. I incorrectly described the operation of the original 1956 Dana limited-slip differential. The pinion pins on the original Dana differential have tapered ends. The pins sit in four V-shaped ramps in the differential case. Under a load, the differential case applies rotational torque to the pinion pins causing them to slide up the V-shaped ramps. This action applies outward force to the side gears and the clutch packs. Thank you to several viewers for pointing out my error.

TIMELINE

0:00 Start

0:08 Introduction

0:32 Open Differential

3:55 Power flow through a differential

6:51 Side gear backlash control

9:09 Differential Demonstration

10:21 MUST SEE Differential Equations

13:12 Automotive differential history

14:44 Dana Corporation's 1955 invention of the automatic locking differential

15:33 Various names for Dana's locking differential

17:23 See a 1963 Chevrolet positraction differential with clutch packs

24:00 How rotating gears apply a clutch pack

26:35 Why limited-slip additive may be required for a clutch-type differential

28:46 See a 1970s era GM positraction differential with clutch packs

29:40 See a 1984 Chevrolet Corvette Limited-Slip differential with clutch packs

30:02 See a 2012 Eaton Posi Limited-Slip differential with clutch packs

34:00 MUST SEE See a worn out 2010 Chevrolet Camaro SS Limited-Slip differential with clutch packs

38:00 See a broken 2005 Jeep Wrangler Rubicon Torsen Type B style limited-slip differential with an air locker

43:51 MUST SEE See the pieces of a Torsen Type B style differential and see how it works

48:03 See a 2002 Toyota Tacoma Electric Locking Differential

51:00 See the Eaton Detroit Trutrac (Similar to the Torsen Type B differential design)

49:55 See a spool with no differential action

53:40 See a Mini-Spool and how to install it

56:35 See the Eaton Locker and learn how it works

1:00:45 Final wrapup

ABOUT US:

DONATE TO OUR DEPARTMENT

Комментарии

1:03:14

1:03:14

0:12:26

0:12:26

0:04:47

0:04:47

0:04:56

0:04:56

0:09:13

0:09:13

0:03:53

0:03:53

0:06:53

0:06:53

0:07:57

0:07:57

0:12:43

0:12:43

0:03:04

0:03:04

0:05:41

0:05:41

0:07:52

0:07:52

0:24:13

0:24:13

0:02:49

0:02:49

0:05:18

0:05:18

0:18:39

0:18:39

0:04:04

0:04:04

0:15:38

0:15:38

0:16:49

0:16:49

0:04:53

0:04:53

0:05:53

0:05:53

0:04:10

0:04:10

0:03:54

0:03:54

0:07:54

0:07:54