filmov

tv

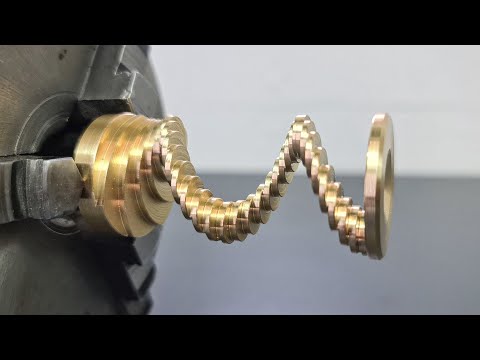

The world's largest lathe in operation

Показать описание

The world's largest lathe in operation

****************************************

We hope you enjoy the interesting Videos of Global Technology TV! Don't forget to sign up! Thanks very much!

* We hope you enjoyed this review!

See below for a full list of assertions:

Music:

* Success Of The Whole Team by WinnieTheMoog

* Video:

- Heavy Machining

- Seco Tools

- The Biggest Lathe in the World Part 01

- The Biggest Lathe in the World Part 02

- The Biggest Lathe in the World Part 03

- The Biggest Lathe in the World Part 04

- Axel Fibro

- CRANK SHAFT MACHINING OF 4000 TON PRESS

- MAYUR SHAH

- Herkules Grinding WS1100 WS600 WS450L

- Maschinenfabrik Herkules

- Hankook Propulsion Shaft Lathe

- Han-Zu Haller

-

- PROFILE ROLL SHAFT MACHINING ON CNC ROLL TURNING MACHINE

- 1600 ton press cranck shaft reconditioning done on heavy duty CNC skoda roll turning machine

- SAFOP CNC LATHE HT18 V@

- RBR Machine Tools Ragnini

********************************************************

* Thank you for your cooperation.

***************************************

*Disclaimer: Global Technology TV is not affiliated with the businesses whose products are shown in this review. Any trademarks depicted are the property of their respective owners.

****************************************

We hope you enjoy the interesting Videos of Global Technology TV! Don't forget to sign up! Thanks very much!

* We hope you enjoyed this review!

See below for a full list of assertions:

Music:

* Success Of The Whole Team by WinnieTheMoog

* Video:

- Heavy Machining

- Seco Tools

- The Biggest Lathe in the World Part 01

- The Biggest Lathe in the World Part 02

- The Biggest Lathe in the World Part 03

- The Biggest Lathe in the World Part 04

- Axel Fibro

- CRANK SHAFT MACHINING OF 4000 TON PRESS

- MAYUR SHAH

- Herkules Grinding WS1100 WS600 WS450L

- Maschinenfabrik Herkules

- Hankook Propulsion Shaft Lathe

- Han-Zu Haller

-

- PROFILE ROLL SHAFT MACHINING ON CNC ROLL TURNING MACHINE

- 1600 ton press cranck shaft reconditioning done on heavy duty CNC skoda roll turning machine

- SAFOP CNC LATHE HT18 V@

- RBR Machine Tools Ragnini

********************************************************

* Thank you for your cooperation.

***************************************

*Disclaimer: Global Technology TV is not affiliated with the businesses whose products are shown in this review. Any trademarks depicted are the property of their respective owners.

Комментарии

0:08:49

0:08:49

0:00:22

0:00:22

0:14:07

0:14:07

0:10:39

0:10:39

0:00:26

0:00:26

0:02:22

0:02:22

0:11:58

0:11:58

0:00:05

0:00:05

0:12:02

0:12:02

0:26:45

0:26:45

0:05:35

0:05:35

0:00:15

0:00:15

0:06:14

0:06:14

0:04:15

0:04:15

0:00:19

0:00:19

0:19:57

0:19:57

0:00:33

0:00:33

0:00:15

0:00:15

0:06:07

0:06:07

0:00:14

0:00:14

0:00:56

0:00:56

0:01:00

0:01:00

0:00:16

0:00:16

0:00:42

0:00:42