filmov

tv

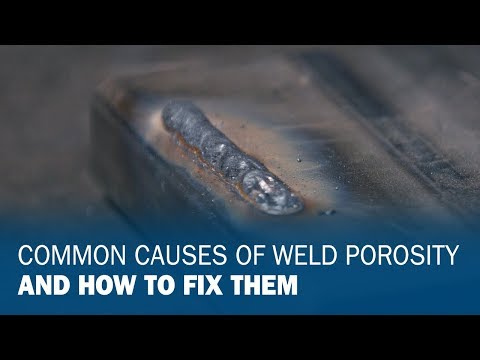

Common Causes of Weld Porosity and How to Fix Them

Показать описание

Have you ever experienced porosity in your welds? Peter Torres from BS Industries provides some common causes of porosity and how to fix them.

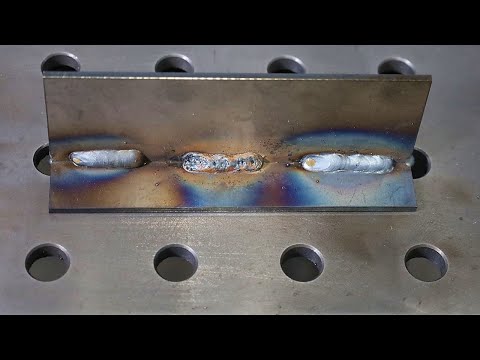

Porosity stems from inside of the weld, where there should be no voids — causing holes to appear in the weld. Common causes of porosity include low gas flow, a hole in the gas line, spatter in the MIG gun plugging the gas diffuser, rusty/contaminated weld wire and oils/contamination on the base metal. Torres provides an example of weld porosity due to low gas flow. By adjusting the flow to manufacturer specs, located on the front of his Millermatic® 252 MIG welder, he is able to fix the issue.

For more information on common weld defects, visit:

---------------------------------------------------------------

CONNECT with Miller Welders:

ABOUT Miller Electric Mfg. LLC:

Miller Electric Mfg. LLC is a leading worldwide manufacturer of Miller® brand arc welding and cutting products. The Miller Welders channel provides the tips and techniques you need to tackle even the most challenging applications, and shares the stories of welders around the world who believe that together, WE BUILD.

Porosity stems from inside of the weld, where there should be no voids — causing holes to appear in the weld. Common causes of porosity include low gas flow, a hole in the gas line, spatter in the MIG gun plugging the gas diffuser, rusty/contaminated weld wire and oils/contamination on the base metal. Torres provides an example of weld porosity due to low gas flow. By adjusting the flow to manufacturer specs, located on the front of his Millermatic® 252 MIG welder, he is able to fix the issue.

For more information on common weld defects, visit:

---------------------------------------------------------------

CONNECT with Miller Welders:

ABOUT Miller Electric Mfg. LLC:

Miller Electric Mfg. LLC is a leading worldwide manufacturer of Miller® brand arc welding and cutting products. The Miller Welders channel provides the tips and techniques you need to tackle even the most challenging applications, and shares the stories of welders around the world who believe that together, WE BUILD.

Комментарии

0:00:38

0:00:38

0:01:26

0:01:26

0:08:11

0:08:11

0:03:45

0:03:45

0:10:42

0:10:42

0:00:49

0:00:49

0:04:41

0:04:41

0:07:28

0:07:28

0:02:05

0:02:05

0:01:05

0:01:05

0:02:07

0:02:07

0:11:14

0:11:14

0:10:50

0:10:50

0:10:39

0:10:39

![[English] Porosity -](https://i.ytimg.com/vi/jxnlMbjDx0Q/hqdefault.jpg) 0:14:55

0:14:55

0:00:31

0:00:31

0:01:31

0:01:31

0:04:08

0:04:08

0:07:28

0:07:28

0:00:21

0:00:21

0:08:04

0:08:04

0:00:58

0:00:58

0:03:47

0:03:47

0:10:51

0:10:51