filmov

tv

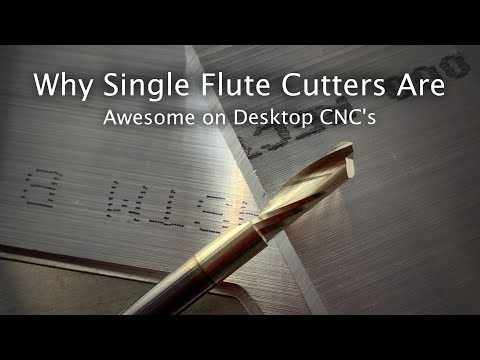

Machining Aluminum with the 278-Z on the Shapeoko - #MaterialMonday

Показать описание

Single flute endmills aren't just for plastic. They're also awesome for aluminum on desktop CNC's. (Don't use your plastic cutters in aluminum though, different geometry.) Here are some speeds and feeds for machining aluminum with our 278-Z on the Shapeoko.

-----

-----

Machining Aluminum with the 278-Z on the Shapeoko - #MaterialMonday

Single Flute Endmills Machining Aluminum on the Nomad - #MaterialMonday

Machining Aluminum Longboard Kicktails - Carbide Cruiser Ep. 4

Shark CNC doing a high MRR cut in aluminum

You Need to Start Machining Metal

Testing High Efficiency Milling Techniques on a Shapeoko 3

milling aluminum on my Shapeoko HDM. Cuts through aluminum like butter!

How I get the smoothest aluminium in Europe!💪🏻🇳🇱 #machine #production #aluminium

How to Decide Which End Mill to Use in Aluminum | A Quick Beginner's Guide to Milling in a Torm...

cnc machining milling aluminum parts manufacturing,Custom precision aluminum cnc processing

Helical milling aluminum

Cutting Aluminum with a 1/8' bit

Cutting Pattern Into Aluminum #stepcraftcnc #cnc #cncmachine

Cutting Aluminum Letter on CNC

Cutting Aluminum - Shapeoko 5 Pro - Video 7

Tool Testing: Dreanique3 flute 6mm dlc end mill on aluminium

1/2 aluminum sheet cut with 3/8” Aluminum bit #satisfying #satisfyingvideo #subscribe #like #viral

CNC machining aluminum parts, low volume production from Modo Rapid

CAM and Machining of the Longboard Deck, Pt. 1 - Carbide Cruiser Ep. 2

Machining 5052 Aluminum on CNC Router

Cutting Aluminum with 1/4' Bit

Aluminum Chipbreaker End Mill to make those stringy chips a thing of the past!

Incredibly fast cutting of aluminium at 30,000mm/min feed

CNC aluminum products processing#cnc #aluminium #production

Комментарии

0:04:31

0:04:31

0:02:29

0:02:29

0:09:00

0:09:00

0:00:49

0:00:49

0:17:54

0:17:54

0:04:19

0:04:19

0:00:16

0:00:16

0:00:29

0:00:29

0:03:25

0:03:25

0:00:21

0:00:21

0:00:42

0:00:42

0:00:59

0:00:59

0:00:22

0:00:22

0:00:16

0:00:16

0:04:21

0:04:21

0:00:22

0:00:22

0:00:13

0:00:13

0:00:29

0:00:29

0:08:39

0:08:39

0:01:01

0:01:01

0:01:00

0:01:00

0:00:07

0:00:07

0:00:14

0:00:14

0:00:40

0:00:40