filmov

tv

Worm & Worm Wheel Free Hobbing Method

Показать описание

Shown here is how a worm and worm wheel was made in the home workshop.

What's it for? The answer can be found here-

What's it for? The answer can be found here-

A simple idea for making a worm gear from a tap drill thread on a lathe

Worm & Worm Wheel Free Hobbing Method

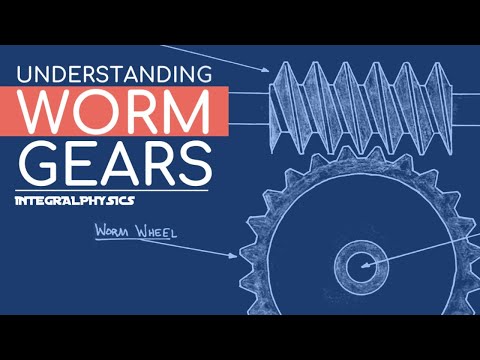

This is why worm gears are so cool...

Worm Gears Explained, Calculated & Modeled

Zero backlash for the worm drive

Making Worm Gears With Taps - BUSTED

WORM & WORM GEAR APPLICATION

WORM GEARS - Forces and Speed Relations in Just Under 15 Minutes!

Free hobbing a worm wheel

Free Hobbing a Wormgear with Tap - A Design & Manufacturing Guide

275. Worm gear reducer || Free download 3D model

Worm Gearbox - CAD simulation Roue et vis sans fin

Making Worm Gears. Harder Than You Might Think

worm gear and worm shaft meshing testing / worm gear set center distance and backlash inspection

machining worm gear wheels

How to model Worm Gears (Gears pt 7/?)

Worm Gear Using FreeCad's Gear Addon

Intermittent worm wheel with cam

How to Make a Worm Gear (Hobbing Process)

Worm Gear Reducer Animation - SolidWorks 2007

FreeHobbing Gears on the lathe Tutorial

Hobbing Brass Worm Gear With DIY Gear Hob

Powered Lathe Slotter Build Part 24. Setting the backlash on the Worm Shaft and Worm Wheel

Making a Worm Gear on Bolt

Комментарии

0:14:44

0:14:44

0:18:45

0:18:45

0:03:12

0:03:12

0:07:32

0:07:32

0:00:27

0:00:27

0:10:07

0:10:07

0:00:45

0:00:45

0:14:36

0:14:36

0:07:42

0:07:42

0:08:12

0:08:12

0:00:15

0:00:15

0:00:51

0:00:51

0:25:17

0:25:17

0:00:24

0:00:24

0:45:25

0:45:25

0:18:37

0:18:37

0:01:34

0:01:34

0:00:21

0:00:21

0:05:09

0:05:09

0:00:19

0:00:19

0:05:14

0:05:14

0:00:39

0:00:39

0:25:17

0:25:17

0:08:08

0:08:08