filmov

tv

Fatigue Failure Analysis

Показать описание

Understanding Fatigue Failure and S-N Curves

Fatigue Failure Analysis

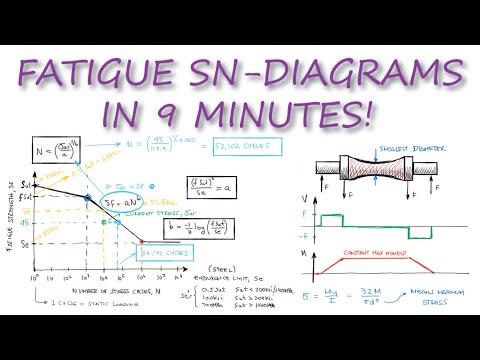

Fatigue (Strength-Number of Cycles) SN-DIAGRAMS in Under 10 Minutes!

FATIGUE FAILURE 💔

Take a Closer Look at Fatigue and Fracture: Fatigue Crack Growth Test

Fatigue Test

Fatigue FAILURE CRITERIA in Just Over 10 Minutes!

ASM Digital Short Course: Failure Analysis: Fatigue Failures

Fatigue Mechanisms

How and When Metals Fail

Mechanics of Materials: Lesson 16 - Fatigue and Creep Failures with S-N Diagram

Fatigue

Fatigue SN Diagrams - Number of Cycles to Fatigue Failure - Example 1

Lecture 23 - Fatigue Failure of Materials (Introduction, Historical Events, S-N Diagram)

Shaft Design for INFINITE LIFE and Fatigue Failure in Just Over 10 Minutes!

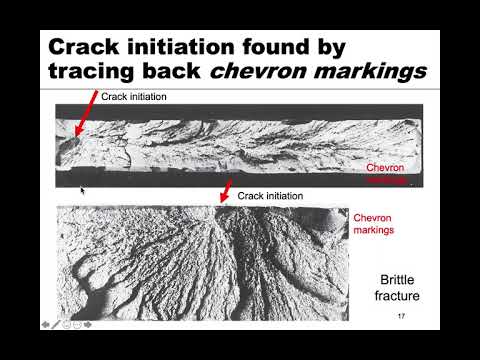

MSE 201 S21 Lecture 26 - Module 2 - Fracture Surfaces

Springs Fatigue and ZIMMERLI Analysis in Just Over 10 Minutes!

Understanding Failure Theories (Tresca, von Mises etc...)

#fatigue failure #analysis #materials

In Our Element: What is Fatigue Failure? | Episode 31

Understanding Fatigue of Composite Materials

Fracture Mechanics video 4 - Fatigue Failure

fatigue failure analysis - part2d.

ch 8 Materials Engineering

Комментарии

0:08:23

0:08:23

0:06:32

0:06:32

0:08:40

0:08:40

0:14:21

0:14:21

0:01:24

0:01:24

0:12:01

0:12:01

0:11:35

0:11:35

0:01:28

0:01:28

0:15:15

0:15:15

0:02:58

0:02:58

0:06:54

0:06:54

0:12:24

0:12:24

0:02:53

0:02:53

0:39:53

0:39:53

0:11:59

0:11:59

0:08:20

0:08:20

0:11:44

0:11:44

0:16:18

0:16:18

0:00:29

0:00:29

0:01:38

0:01:38

0:16:03

0:16:03

0:01:37

0:01:37

0:19:15

0:19:15

1:38:42

1:38:42