filmov

tv

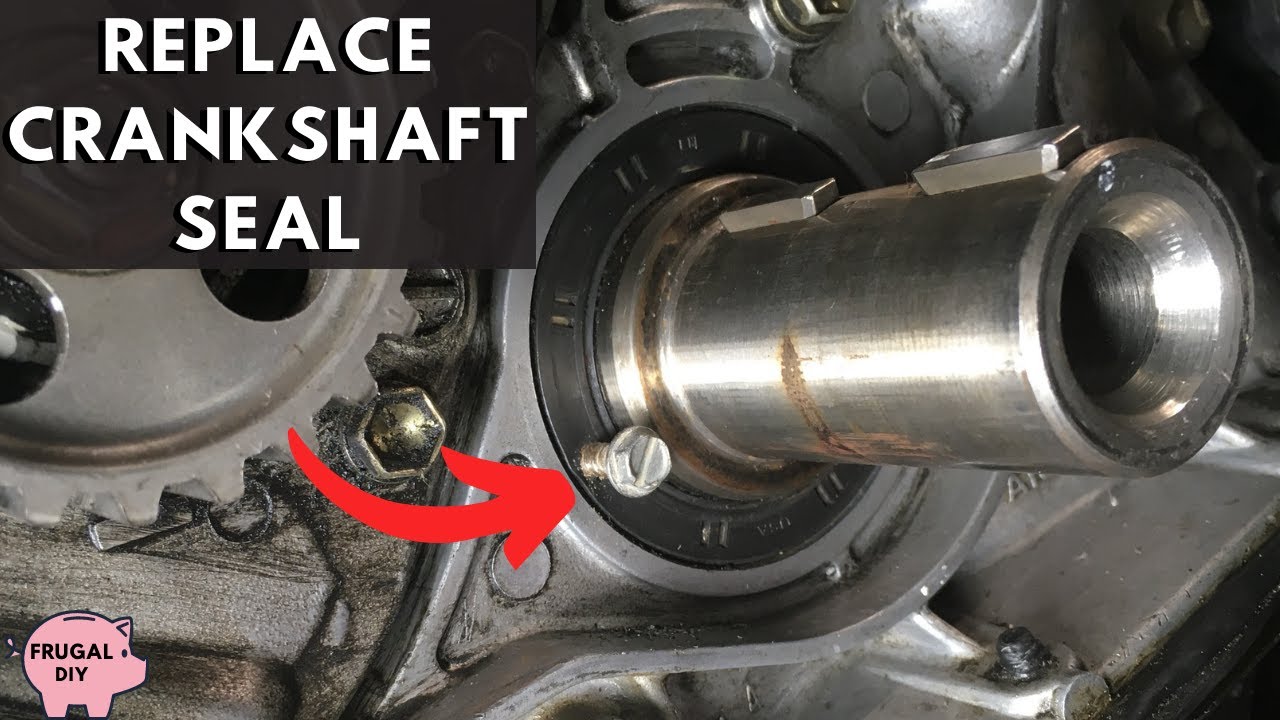

Remove and Replace Crankshaft Seal

Показать описание

We used an 1/8" drill bit and a sheet metal screw to remove the crankshaft seal on my 1995 Toyota Camry. We used the crankshaft sprocket to push the seal in square and then used a 2" piece of ABS pipe and piece of wood to seat the crankshaft seal into its housing.

Remove and Replace Crankshaft Seal

How to Replace Crankshaft Seal on Your Car

Super Easy Crankshaft Seal Removal

how to change crankshaft oil seal/ how to replace front crankshaft oil seal

4 Ways To Remove Camshaft And Crankshaft Seals

Front Crankshaft Seal DIY (No Special Tools) - BMW N55 Engine Rebuild Project Part 8

How to Replace Crankshaft Seal 04-09 Subaru Outback

Front Main Crankshaft Seal Replacement TDI ALH VW

Replace Crankshaft Oil Seal

Easy How To Replace Crankshaft seal 2007-2011 Honda Accord(Low Quality Video)

Oil Seal Replacement - Small Engine Crankshaft Seal

Rear Main Seal Replacement. Easy DIY

How To Replace A Crankshaft Seal On A Two Stroke Motorcycle 🔧⚙️🔩 KTM Husqvarna 300/250 xc xcw...

OLD MECHANICS TRICK TO REPLACE CRANKSHAFT SEALS!

HOW-TO Replace A Lawnmower Crankshaft Seal

BMW F30 crankshaft seal removal and installation ditailed video/ Замена переднего сальника коленвала...

How to Rear Main Seal Replace - Crankshaft Seal Replacement Leak Repair How To DIY

How to REMOVE the Small Crankshaft Seal on a Stihl Chainsaw – WITHOUT Buying Expensive Tools!!

How to Avoid Failure Replacing a Front Crankshaft Seal: Example Shown On Older Mercedes Diesel

How to replace front crankshaft oil seal:how to fix crankshaft oil leak(oil leak fix toyota prado)

How to replace the crankshaft oil seal and harmonic damper - Mercedes w169/w245 - A/B class

How to remove old crankshaft seal and install new one. Easy crankshaft change.

FRONT CRANKSHAFT SEAL REPLACEMENT REMOVAL HYUNDAI KIA 2.4 GDI, CRANKSHAFT SEAL OIL LEAK

Volkswagen Golf mk2 crankshaft oil seal replacement pt1

Комментарии

0:07:40

0:07:40

0:03:56

0:03:56

0:02:43

0:02:43

0:01:21

0:01:21

0:01:48

0:01:48

0:08:03

0:08:03

1:07:53

1:07:53

0:05:15

0:05:15

0:03:50

0:03:50

0:08:20

0:08:20

0:09:01

0:09:01

0:04:56

0:04:56

0:21:44

0:21:44

0:04:44

0:04:44

0:06:12

0:06:12

0:10:21

0:10:21

0:10:04

0:10:04

0:06:29

0:06:29

0:09:41

0:09:41

0:05:08

0:05:08

0:12:38

0:12:38

0:12:04

0:12:04

0:05:21

0:05:21

0:09:55

0:09:55