filmov

tv

Run a Hard Drive Brushless Motor Without Driver

Показать описание

Simple way to run a hard drive motor without driver

Support Ludic Science on Patreon:

Run a Hard Disk Drive Brushless Motor With A Phone Charger

Run a Hard Drive Brushless Motor Without Driver

Unlock the Potential of Your Old Notebook Hard Drives: Build a Drone Engine! #zaferyildiz #diy

Running Motor HDD without ESC

How to run a HDD motor with a mini power supply.

Run a Hard Drive Brushless Motor

BLDC MOTOR inside hard disk #viral #shorts

#diy how to connect DC power with HDD motor #hdd

How To Run a Hard Drive Brushless Motor

How to Run Hard Disk Drive Motor || High Speed Running Brushless Motor

Running HDD motor with ESC

Running a Hard Disk Brushless Motor with ESC and DX8 #femtophysiker #rchobby #hdd #spektrumrc

how to remove bldc motor from old hard disk, how to connect motor to xr 105 bldc motor driver

HOW TO MAKE | POWER SUPPLY FOR HDD | HARD DRIVE SANDER | HARD DRIVER GRINDER | Technical Institute |

How to run without arduino and esc.

Run HDD Brushless Motor || Brushless Motor

How to run hard disk (brushless motor)#shorts

How to Run Hard Drive Disk Brushless Motor with A Mobile Phone Charger

Hard disk grinder | science project #tech #project #science

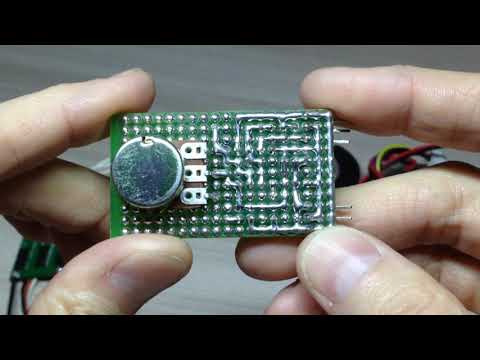

Brushless BLDC motor ESC controller using irfz44, CD, HDD motor driver

How to make BLDC motor ESC using mosfet

Hdd for Brushless Motor Running ESC Control For Servo Tester - Run a Hard Drive Brushless Motor

Run HDD motor without ESC | uses 7805

Make brushless motor run on 3 mosfet #shorts

Комментарии

0:10:37

0:10:37

0:05:03

0:05:03

0:01:01

0:01:01

0:07:58

0:07:58

0:04:05

0:04:05

0:02:28

0:02:28

0:00:09

0:00:09

0:00:59

0:00:59

0:04:27

0:04:27

0:06:00

0:06:00

0:00:22

0:00:22

0:01:04

0:01:04

0:08:00

0:08:00

0:06:53

0:06:53

0:02:55

0:02:55

0:00:32

0:00:32

0:00:50

0:00:50

0:06:24

0:06:24

0:00:24

0:00:24

0:12:09

0:12:09

0:08:58

0:08:58

0:20:24

0:20:24

0:11:06

0:11:06

0:01:00

0:01:00