filmov

tv

Homemade x-ray tube - how i made it ☢

Показать описание

In this video i will show you the results of my homemade vacuum tube attempts. The greatest improvement is given by the use of a titanium getter pump to reach vacuum levels like in industrial x-ray tubes.

Homemade x-ray tube - how i made it ☢

DIY X-ray Machine

Making X-rays in my basement using parts from an old Tv

X Ray Vacuum Tube #nuclear #radiation #physics #highvoltage #engineering #science #energy #xray

Built My Own X-Ray After a Hospital Charged Me $69,210.32

DIY testing eBay X-ray tube- Part 1

Turning a test tube into an x ray tube

Homemade fluoroscopic X-ray – HDD, FDD and vacuum tubes ! #3/3

How to build a nuke

Home Made X-Ray Images

X-ray machine diy

Homemade fluoroscopic X-ray / fluoroskopický rentgen #2/3

Electron Beam Radiation From Home Made Cathode Ray Tube

DIY X-ray CT scanner controlled by an Arduino

X ray tube with not very good vacuum ! look at the color !

My DIY X-Ray Tube Components and Description

XD3 X-Ray Tube

Building a DIY CT/CAT scanner for 200$

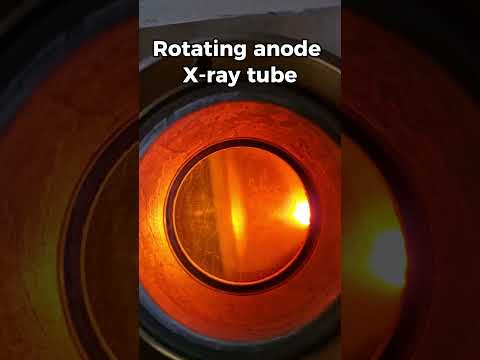

Rotating anode X-ray tube #xray #electronic #vacuumtube #diy #radiation #education #medicalequipment

X-Ray vacuum tube DIY

I Made My Own X-Ray Machine

Scientific Glassblowing, making X-ray tubes.

Homemade X-Ray pictures

Selbstbau Röntgengerät - homemade xray machine

Комментарии

0:09:59

0:09:59

0:15:22

0:15:22

0:00:59

0:00:59

0:00:46

0:00:46

0:17:08

0:17:08

0:00:11

0:00:11

0:06:17

0:06:17

0:02:18

0:02:18

0:05:36

0:05:36

0:08:27

0:08:27

0:19:00

0:19:00

0:03:32

0:03:32

0:00:12

0:00:12

0:06:36

0:06:36

0:00:27

0:00:27

0:06:51

0:06:51

0:00:16

0:00:16

0:14:38

0:14:38

0:00:18

0:00:18

0:00:39

0:00:39

0:08:32

0:08:32

0:00:26

0:00:26

0:03:33

0:03:33

0:02:40

0:02:40