filmov

tv

Tiling on Your CNC Router

Показать описание

Tiling allows you to make items that far exceed your machine size. Carbide 3D helps you GO BIG with this new software feature. Kevin details the core functions you'll need to understand.

Tiling is now included for all Carbide Create Pro Subscribers.

Tiling is now included for all Carbide Create Pro Subscribers.

Tiling on Your CNC Router

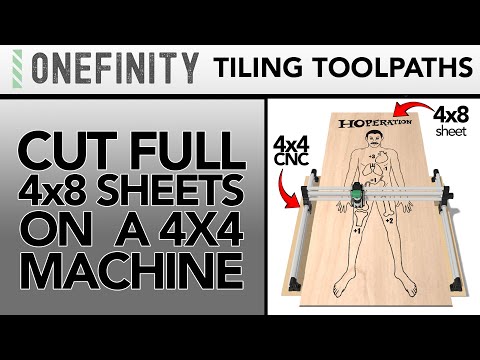

EP. 30 Onefinity CNC - Tiling a Life Sized Operation Cornhole Board

Cutting Larger Than Machine with Tiling

Making Large Parts on a Hobby-level CNC Router - Tiling Tutorial with Fusion 360

How To Make Larger Projects Than Your CNC Table Size | ToolsToday

Magic of Tiling BIG Signs With a Small CNC - VCarve / Onefinity CNC

Learn How To Tile In Carbide Create for Custom CNC Flag with this Simple Tutorial

CNC Router on Ceramic + Glass Tiles

CNC Router Lesson: Tiling - Cutting Material Larger than your CNC

2. Milling Leg Blanks - PRO TIP: Fusion 360 CAM Tiling for Furniture Pieces Longer Than the CNC Bed

How to: Flatten Stock on your CNC Router

When your project doesn't fit

Tiling on a work piece on a Bob's E3 using Vcarve Desktop

Tiling in VCARVE PRO! It’s NOT That Hard to Do

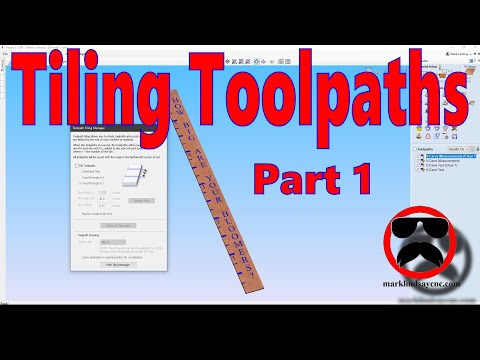

Tiling Toolpaths Part 1 – Design, Toolpath, and Save G-Code

How to make BIG signs on a small CNC // Tiling

Tile Project using LightBurn

Mastering CNC Tiling Techniques using Vectric VCarve Pro

How to Carve a Large Sign/Flag on a CNC / How to Tile Using Carbide Create / Tiling on Shapeoko

Tiling by CNC PRO

How To Cut Parts Bigger than your CNC Bed with Fusion 360

OMNI CNC Router works on the tile(2)

How to Make a Big Rustic Flag on a Small CNC (Tiling)

CNC Shark Tiling Function (VCarve) Overview | Glass Impressions

Комментарии

0:06:01

0:06:01

0:08:24

0:08:24

0:01:00

0:01:00

0:09:56

0:09:56

0:04:29

0:04:29

0:24:17

0:24:17

0:07:40

0:07:40

0:05:37

0:05:37

0:12:28

0:12:28

0:08:19

0:08:19

0:07:19

0:07:19

0:00:36

0:00:36

0:05:57

0:05:57

0:24:29

0:24:29

0:26:17

0:26:17

0:11:36

0:11:36

0:04:47

0:04:47

0:14:37

0:14:37

0:12:48

0:12:48

0:02:51

0:02:51

0:12:51

0:12:51

0:03:05

0:03:05

0:14:42

0:14:42

0:07:13

0:07:13