filmov

tv

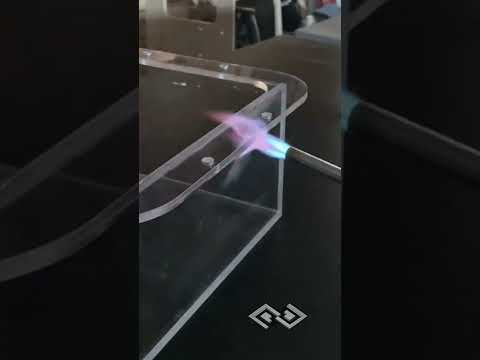

Laser Cleaning vs Manual Buffing - Rust removal

Показать описание

𝐒𝐚𝐯𝐞 𝐭𝐢𝐦𝐞 𝐚𝐧𝐝 𝐦𝐨𝐧𝐞𝐲 𝐰𝐢𝐭𝐡 𝐋𝐚𝐬𝐞𝐫 𝐂𝐥𝐞𝐚𝐧𝐢𝐧𝐠

Traditional methods like mechanical buffing, sandblasting and chemical etching require expensive consumables and can be extremely harmful to the environment and employees. Some of these procedures require abrasive compounds to remove unwanted layers of rust, paint or material. These compounds can be expensive, time and energy consuming to clean, and can damage surfaces if not done correctly.

On the other hand, 𝐋𝐚𝐬𝐞𝐫 𝐂𝐥𝐞𝐚𝐧𝐢𝐧𝐠 uses just light energy, no consumables are needed, and is controlled by computer programs for a precise layer removal. Additionally the laser cleaning process can be fully automated. High quality CE certified Lasers are also environmentally friendly and safe for workers, it is a non-contact process, and there is no damage to the surfaces being cleaned.

.

.

.

#lasercleaning #lasertechnology # #quality #savetimeandmoney #innovation #innovationtechnology #environmentalfriendly #chemicalfree

Traditional methods like mechanical buffing, sandblasting and chemical etching require expensive consumables and can be extremely harmful to the environment and employees. Some of these procedures require abrasive compounds to remove unwanted layers of rust, paint or material. These compounds can be expensive, time and energy consuming to clean, and can damage surfaces if not done correctly.

On the other hand, 𝐋𝐚𝐬𝐞𝐫 𝐂𝐥𝐞𝐚𝐧𝐢𝐧𝐠 uses just light energy, no consumables are needed, and is controlled by computer programs for a precise layer removal. Additionally the laser cleaning process can be fully automated. High quality CE certified Lasers are also environmentally friendly and safe for workers, it is a non-contact process, and there is no damage to the surfaces being cleaned.

.

.

.

#lasercleaning #lasertechnology # #quality #savetimeandmoney #innovation #innovationtechnology #environmentalfriendly #chemicalfree

0:00:28

0:00:28

0:00:14

0:00:14

0:00:13

0:00:13

0:00:12

0:00:12

0:00:21

0:00:21

0:02:17

0:02:17

0:00:16

0:00:16

0:00:05

0:00:05

0:00:28

0:00:28

0:00:39

0:00:39

0:00:59

0:00:59

0:00:24

0:00:24

0:00:24

0:00:24

0:00:09

0:00:09

0:00:46

0:00:46

0:00:18

0:00:18

0:00:10

0:00:10

0:00:26

0:00:26

0:00:06

0:00:06

0:00:12

0:00:12

0:00:31

0:00:31

0:00:30

0:00:30

0:00:11

0:00:11

0:00:13

0:00:13