filmov

tv

PLC Programming Example – Pick and Place Testing

Показать описание

More information can be obtained at our website including all of the links and downloads mentioned in the video.

PLC Programming Example – Pick and Place - Video

This video will show you the sequence of operation and the testing of the final project.

We will apply the five steps to PLC program development to a pick and place robot example. The example will use a BRX PLC communicating to Factory IO (3D Software Simulator). Developing the PLC program is a process that can be clearly defined. In our series on the five steps to PLC program development we have done some similar practical examples.

Here is a review of the steps:

1.Define the task

2.Define the inputs and outputs

3.Develop a logical sequence of operation

4.Develop the PLC program

5.Test the program

Previous PLC Programming Examples using the Five Steps to PLC Program Development:

Five Steps to PLC Program Development - Press

Press Video

Process Mixer

Process Mixer Video

Process Mixer Test Simulation

Shift Register Conveyor Reject

Shift Register Conveyor Reject Video

Paint Spraying

Paint Spraying Video

Delay Starting of 7 Motors

Delay Starting of 7 Motors Video

PLC Programming Example – Pick and Place - Video

This video will show you the sequence of operation and the testing of the final project.

We will apply the five steps to PLC program development to a pick and place robot example. The example will use a BRX PLC communicating to Factory IO (3D Software Simulator). Developing the PLC program is a process that can be clearly defined. In our series on the five steps to PLC program development we have done some similar practical examples.

Here is a review of the steps:

1.Define the task

2.Define the inputs and outputs

3.Develop a logical sequence of operation

4.Develop the PLC program

5.Test the program

Previous PLC Programming Examples using the Five Steps to PLC Program Development:

Five Steps to PLC Program Development - Press

Press Video

Process Mixer

Process Mixer Video

Process Mixer Test Simulation

Shift Register Conveyor Reject

Shift Register Conveyor Reject Video

Paint Spraying

Paint Spraying Video

Delay Starting of 7 Motors

Delay Starting of 7 Motors Video

PLC Programming Example – Pick and Place

PLC Programming Example – Pick and Place Testing

PLC programming of pick and place robot arm module. 'automatic'

Pick and Place Robotic Arm programming in PLC Programming Tutorials for Beginners

PLC Ladder Logic Basics For Beginners With A Working Conveyor

PLC Programming for Pick & Place Robot -

PLC Programming Tutorials for Beginners || Ladder logic for pusher

Pick & Place Robot | Industrial Robot | PLC Program | TIA Portal | #siemensplc #factoryio #s7120...

PLC Pneumatic Pick-and-Place

PLC based Pick and Place Automation System Conveyor Transfer

How to Program for Bottle Divider and Conveyors || PLC Programming Tutorials for Beginners

PLC Pick & Place

Pick & Place |ITS | PLC Programming

Pick & Place Robot with Delta PLC in Factory IO

Pick and Place, plc module training

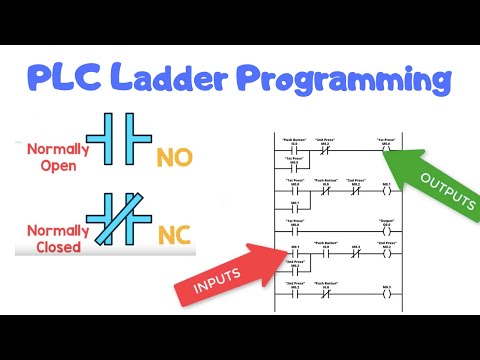

Introduction to PLC Ladder Program: NO and NC Contacts Explained | Automation and PLC Series Part 4

😋 ❤️ CONTROL 365 with GX WORKS, Pick & Place, PLC simulator

Pick and Place Robot using PLC and Pneumatics

PLC-Based XYZ Motion Gantry Pick and Place Simulation

PLC Programming Example – Palletizer Drum Instructions

What is a PLC? (90 sec)

Factory IO tutorial Pick and Place ( Basic ) | TIA portal | S7-1200 PLC

Object Size detection and sorting using PLC Ladder Logic || Part #1

PLC Programming Example of a Palletizer

Комментарии

0:12:58

0:12:58

0:06:11

0:06:11

0:00:21

0:00:21

0:10:47

0:10:47

0:06:35

0:06:35

0:16:22

0:16:22

0:03:48

0:03:48

0:05:50

0:05:50

0:00:53

0:00:53

0:02:03

0:02:03

0:09:25

0:09:25

0:03:43

0:03:43

0:03:29

0:03:29

0:02:07

0:02:07

0:00:36

0:00:36

0:04:45

0:04:45

0:02:24

0:02:24

0:10:20

0:10:20

0:02:08

0:02:08

0:13:00

0:13:00

0:01:39

0:01:39

0:03:48

0:03:48

0:06:25

0:06:25

0:15:04

0:15:04