filmov

tv

sewage treatment plant onboard ship - biological sewage treatment plant in ship

Показать описание

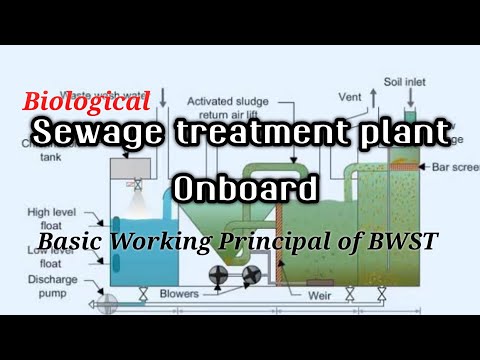

Raw sewage is passed to an aeration chamber and air is supplied through diffusers. This promotes the action of aerobic bacteria which break down the sewage into carbon di-oxide, water and inorganic waste. Figure below shows a typical biological sewage treatment plant.Sewage then passes into the clarification or settling chamber. Any solids that settle out are returned via an air lift to the aeration chamber which ensures that they are fully broken down. The sample applies to any surface scum. A small vane type air compressor supplies the air for air diffusers and air lift.

The clear liquid then passes through the chlorinator where the liquid is disinfected, into the chlorination chamber. The chamber has float switches, which control the discharge pump, and a high level alarm.

Although the sewage treatment plant runs automatically, without regular maintenance the unit will not function properly and anaerobic bacteria may promote the formation of hydrogen sulphide and methane, both of which are hazardous.

The chambers need to be cleaned out occasionally to remove any accumulated matter. The aeration diffusers should be checked to ensure they are clear and that air is bubbling from them. The air lift returns should also be checked to make sure they function correctly. These usually have a clear plastic pipe so that the sludge can be seen returning to the aeration chamber.

The internal tank coating should be inspected for any signs of cracking or blistering.

When cleaning out a sewage unit rubber gloves and a mask should be worn. After overhaul the external surfaces of the unit and surroundings are to be washed down with disinfectant. Hands should also be thoroughly scrubbed and overalls washed.

Reference

“Operation and Maintenance of Machinery in Motor Ships” by N.E. Chell

The clear liquid then passes through the chlorinator where the liquid is disinfected, into the chlorination chamber. The chamber has float switches, which control the discharge pump, and a high level alarm.

Although the sewage treatment plant runs automatically, without regular maintenance the unit will not function properly and anaerobic bacteria may promote the formation of hydrogen sulphide and methane, both of which are hazardous.

The chambers need to be cleaned out occasionally to remove any accumulated matter. The aeration diffusers should be checked to ensure they are clear and that air is bubbling from them. The air lift returns should also be checked to make sure they function correctly. These usually have a clear plastic pipe so that the sludge can be seen returning to the aeration chamber.

The internal tank coating should be inspected for any signs of cracking or blistering.

When cleaning out a sewage unit rubber gloves and a mask should be worn. After overhaul the external surfaces of the unit and surroundings are to be washed down with disinfectant. Hands should also be thoroughly scrubbed and overalls washed.

Reference

“Operation and Maintenance of Machinery in Motor Ships” by N.E. Chell

0:02:11

0:02:11

0:02:00

0:02:00

0:09:02

0:09:02

0:10:19

0:10:19

0:21:18

0:21:18

0:00:22

0:00:22

0:03:14

0:03:14

0:02:07

0:02:07

0:09:05

0:09:05

0:09:20

0:09:20

0:06:07

0:06:07

0:06:23

0:06:23

0:04:54

0:04:54

0:22:23

0:22:23

0:22:19

0:22:19

0:09:01

0:09:01

0:01:32

0:01:32

0:03:49

0:03:49

0:13:38

0:13:38

0:06:11

0:06:11

0:00:31

0:00:31

0:01:56

0:01:56

0:14:36

0:14:36

0:08:09

0:08:09