filmov

tv

Basic Rules for Lapping length in Beam - Lap length in RCC Beam || By CivilGuruji

Показать описание

#civilguruji #civilengineers #Beam #Lapping

Basic Rules for Lapping length in Beam - Lap length in RCC Beam

Get 75% Discount Use Coupon Code :- GURUJI

For Training Call Now : 9111001234

ABOUT THIS VIDEO :-

In this video Er. Akash Bohare & Corporate Trainer of Civil Guruji (Civil Engineers Training Institute) is Explaining About Basic Rules for Lapping length in Beam - Lap length in RCC Beam

The perfect zone for lapping is where the moments remain zero for continuous beams or in the bending moment diagram, where the values surpass the x-axis or remain at L/4 for simply supported beams. The lapping should be provided on tension zone as moments will be created with greater tension.

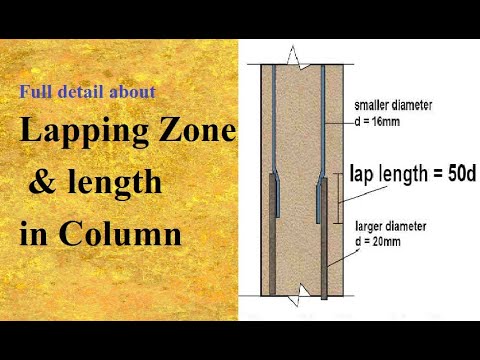

Lap Length | Lap length of Beams | Lap Length of Slabs | Lap Length of Columns | Lapping Zone of Beams and Columns. Lap length can be defined as the length that is provided so as to allow the overlapping of two reinforcement bars thereby ensuring safe and efficient transfer of load from one bar to another.

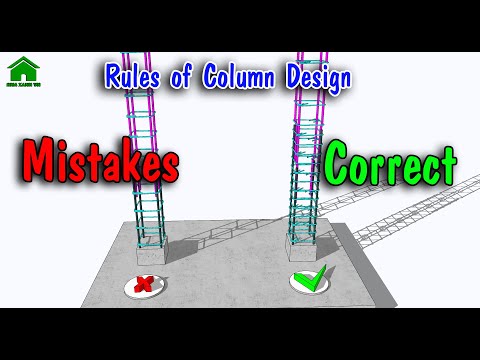

When we provide lapping in a column, all the rebars should be lapped in zone-B as shown in the drawing. The top and bottom portion of the column, i.e. zone-A ( L/4 length ) should be avoided as there will be a maximum moment in this zone due to lateral forces acting on the column.

This amount of overlap between two bars is called “lap length”. Lapping is usually done where minimum bending stress is encountered. In general, lap length is 50d which means 50 times the bar diameter, if both bars are of same diameter.

Basic Rules for Lapping length in Beam - Lap length in RCC Beam

Get 75% Discount Use Coupon Code :- GURUJI

For Training Call Now : 9111001234

ABOUT THIS VIDEO :-

In this video Er. Akash Bohare & Corporate Trainer of Civil Guruji (Civil Engineers Training Institute) is Explaining About Basic Rules for Lapping length in Beam - Lap length in RCC Beam

The perfect zone for lapping is where the moments remain zero for continuous beams or in the bending moment diagram, where the values surpass the x-axis or remain at L/4 for simply supported beams. The lapping should be provided on tension zone as moments will be created with greater tension.

Lap Length | Lap length of Beams | Lap Length of Slabs | Lap Length of Columns | Lapping Zone of Beams and Columns. Lap length can be defined as the length that is provided so as to allow the overlapping of two reinforcement bars thereby ensuring safe and efficient transfer of load from one bar to another.

When we provide lapping in a column, all the rebars should be lapped in zone-B as shown in the drawing. The top and bottom portion of the column, i.e. zone-A ( L/4 length ) should be avoided as there will be a maximum moment in this zone due to lateral forces acting on the column.

This amount of overlap between two bars is called “lap length”. Lapping is usually done where minimum bending stress is encountered. In general, lap length is 50d which means 50 times the bar diameter, if both bars are of same diameter.

Комментарии

0:02:46

0:02:46

0:11:05

0:11:05

0:03:30

0:03:30

0:10:02

0:10:02

0:08:18

0:08:18

0:13:56

0:13:56

0:03:07

0:03:07

0:05:27

0:05:27

0:13:34

0:13:34

0:03:14

0:03:14

0:01:56

0:01:56

0:15:04

0:15:04

0:01:56

0:01:56

0:03:03

0:03:03

0:03:20

0:03:20

0:10:09

0:10:09

0:06:22

0:06:22

0:09:10

0:09:10

0:04:45

0:04:45

0:04:10

0:04:10

0:03:34

0:03:34

0:10:10

0:10:10

0:04:44

0:04:44

0:10:01

0:10:01